Monterrey, Nuevo León a 3 de Junio de 200 3

Lic. Arturo Azuara Flores:

Director de Asesoría Legal del Sistema

Por medio de la presente hago constar que soy autor y titular de la obra

titulada:" A computer-aided framework for manufactura bility

analysis of robot-made assemblies

", en los sucesivo LA OBRA, en virtud de lo cual autorizo a el

Instituto Tecnológico y de Estudios Superiores de Monterrey (EL INSTITUTO)

para que efectúe la divulgación, publicación, comunicación pública, distribución y

reproducción, así como la digitalización de la misma, con fines académicos o

propios al objeto de EL INSTITUTO.

El Instituto se compromete a respetar en todo momento mi autoría y a

otorgarme el crédito correspondiente en todas las actividades mencionadas

anteriormente de la obra.

A computer-aided framework for manufacturability analysis of

robot-made assemblies-Edición Única

Title

A computer-aided framework for manufacturability

analysis of robot-made assemblies-Edición Única

Authors

Olivia Maricela Barrón Cano

Affiliation

ITESM

Issue Date

2003-05-01

Item type

Tesis

Rights

Open Access

Downloaded

19-Jan-2017 05:50:09

Olivia Mariela Barron Cano

Ph.D. Thesis

Instituto Tenologio y de Estudios

Superiores de Monterrey

Campus Monterrey

Graduate Programs of Eletronis, Computer Siene,

Informatis and Communiations

TheommitteemembersherebyreommendthethesispresentedbyOliviaMariela

Barron Cano to be aepted as a partialrequiremente to be admitted tothe Degree

of Dotor of Philosophy in Artiial Intelligene.

Commitee Members

Dr. Jose LuisGordillo Mososo Dr. LuisEnrique SuarSuar

Advisor

Dr. Arturo Molina Gutierrez Dr. JoseManuel Sanhez Gara

Dr. DavidGarza Salazar

Diretor of Graduate Programs of Eletronis,

Computer Siene, Informatis and Communiations

my own researh.

OliviaMariela BarronCano

Monterrey

Ithasbeenproventhatmanufaturingenterprisesouldobtainsigniantsavings,both

intime andmoney,by makinghangesduringtheearlyphases ofdesignof their

prod-uts[Whitney 90℄. Thisfathasleadtothedevelopmentofanumberofmethodologies

and software systemstailoredtogivedesigners toolstoanalyzemanufaturability

dur-ing the design stage [Priest 01℄.

Two dierent approahes ould be taken for analyzing the manufaturability of a

given design. One is to use metris based on dierent fators, like number of

oper-ations, omplexity of the involved operations, et. The other one is to simulate the

manufaturing proess to see if it is feasible tobuild the design without having to do

a physialmok-up. In the ase ofroboti assembly of eletro-mehanialdevies, the

seond approah ismoreuseful beausedetailedassemblyplansare generatedinorder

to dothe analysis [Choi00℄.

In order to test if a given design ould be manufatured by a spei roboti ell,

designers must answer a number of questions about sequening, stability, xturing,

grasping, motion planning and tool aessibility. Although several tools have been

developed for omputing some of the answers required by designers, they have been

developed inanisolatedfashionmakinghardthe integrationoftheirresults. Eahtool

uses its own objet models, sets of onstraints, sale fators, and base units leading

to inompatibility problems when designers have to use the output from one tool as

the input foranother one. Unfortunately,these problems makedesigners would rather

answertheirquestionsempirially,one byone, and thusa systemthatintegratesthese

toolsisneed. Suhasystemwillrelievedesignersfromtheintegrationburden allowing

them to fous onthe reative aspets of their jobs.

This thesis desribes a omputer-aided framework that enables the integration of

software tools for manufaturability analysis. Based on a given desription of the

assembly, a feasible assembly sequene, a roboti ell model, a set of software tools

and a desription of the order in whih the tools must be alled, the framework is

apable of givingdetailed plans for the assembly (if they exist) or feedbak about the

manufaturability problems (when it is impossible to make the assembly in the given

ell). The framework is designed in suh a way the software tools do not have to be

run loally,instead they ould berun in any plae inthe world whihan be aessed

trough Internet.

Two Web-aesible omputer systems were implemented to aomplish this

re-searh;the rst one wasdeveloped as amean togure out the problems that must be

takled down tointegrateseveral software tools,and the seond one was developed to

show the feasibility of buildingthe proposed framework.

The major ontributions of this researh an beharaterized as follows:

Denition and formal speiation of a entral assembly-oriented data model

whih inludes informationabout assemblies, roboti ells and onstraints. The

data modelisbasedona omprehensivedomain ontologythat enablesthe

inter-operation of manufaturability analysis software tools by managinginformation

Denitionof amodularframeworkfor integrationof software toolsand feedbak

mehanisms. Ablakboxintegrationapproahisusedallowingthesoftwaretools

to be implemented in any omputer language as long as they use the standard

input/output system to read variables and output results. Constraint

manage-mentisused as aommuniation mehanismbetween the tools. The integration

of their solutions is made by testing eah solution generated to keep oherene

withthe requirementsofallthetools. Sokets are usedtoommuniatewith the

software tools,sothey ould beruninany omputer pluggedtothe World-Wide

Web atany loationaround the world.

A simple example was set and four tests were run in order to prove the main

harateristis of the framework. Also, a survey was designed and applied to expert

IwouldliketothankDr. PradeepKhoslaforseveralreasons. Heallowedmetoontinue

mydotoralstudiesasavisitingresearher intheEngineeringDesignResearhCenter

(EDRC) at Carnegie Mellon University for one year. As my external advisor, he

provided me with invaluable support, guidane, and insight to help me aomplish

my researh eetively. Also, due to the generosity of the EDRC, I had aess to

many vitalresoures as urrent related journals, publiations, letures, seminars, and

software whihplayed animportantrole inorder toomplete the theoretiomponent

members. I am very grateful to Dr. Gordillo for his advie, guidane, and patiene.

I am also grateful to Dr. Molina, Dr. Sanhez, and Dr. Suar, who kindly agreed to

join my ommittee and provide very valuable omments onmy thesis draft.

I would like to express my gratitude to those who were present in the dierent

phases in whih I was involved during this researh. I appreiate the supportreeived

from Dr. Franiso Cantu to start this PhD Program. I would also like to thank all

the people who enlightened my stay in the Engineering Design Researh Center, at

Carnegie Mellon University, speially Dr. Pradeep Khosla, Dr. Raju Matikalli, Dr.

Satyandra Gupta and Peter Brown. I also appreiate the support I reeived from my

friends there,speially Otavio, Sandy and Antonio.

I am grateful tothe Center for Intelligent Systems at ITESM, Campus Monterrey

for the researh failitiesand to allhismembers. Very speial thanks toSantiago and

Leonardo, my fellows inthe dotoral program.

I give my appreiation to my whole family, speially to my husband, my mother

and my motherinlawwhohad alwayssupportedme, takingare ofmykidswhenever

I had tofous on my thesis.

Finally, I appreiate the nanial support of ITESM, Campus Monterrey and

To the memory of my father, who lives in my hearth

Committee Delaration i

Delaration ii

Abstrat iv

Speial Aknowledgements v

Aknowledgements vii

Dediation ix

List of Figures xiv

1 Introdution 1

1.1 Problem Statement . . . 2

1.2 Proposed Solution. . . 4

1.3 Main Contributions . . . 6

1.4 Organization . . . 7

2 Related Work 9 2.1 Assembly DataModelling . . . 9

2.2 Assembly Planning . . . 10

2.2.1 General planners . . . 10

2.2.2 Sequeners . . . 11

2.2.3 Other approahes . . . 12

2.3 Graspingand Fixturing. . . 13

2.4 Software Integration Systems . . . 15

2.5 Blakboard systems . . . 16

2.6 Summary . . . 18

3 Framework 19 3.1 Framework overview . . . 20

3.2 InternalStrutures . . . 23

3.2.2 Roboti Cell . . . 27

3.2.3 Constraints . . . 30

3.2.4 HistoryReord . . . 31

3.2.5 DataInterfaes . . . 32

3.2.6 SolutionsTree . . . 33

3.3 Central Constraint Manager and SpeializedAnalyzers . . . 35

3.4 Summary . . . 37

4 TestBed 39 4.1 Example . . . 39

4.2 Usingthe testbed to solve the example . . . 41

4.3 Summary . . . 47

5 Computer System Desription 49 5.1 DenitionsMenu . . . 49

5.1.1 Assembly . . . 51

5.1.2 Proess . . . 53

5.2 AnalysisMenu . . . 54

5.3 Status Menu . . . 54

5.3.1 System Messages Retrieval . . . 54

5.3.2 HistoryReord Retrieval . . . 55

5.4 Example . . . 55

5.5 Evaluationby designers. . . 63

5.6 Summary . . . 65

6 Conlusions and further work 67 6.1 Contributions . . . 68

6.1.1 Central Assembly-Oriented Data model . . . 68

6.1.2 Method . . . 69

6.2 Signianeand Impliationsof the Researh. . . 70

6.3 MainLimitationsand suggestions for further work . . . 70

Referenes 72

1.1 Assembly and Robot . . . 3

1.2 Framework Arhiteture Overview . . . 6

3.1 Framework Arhiteture Overview . . . 21

3.2 Framework arhiteture exeution owfor a typialsession . . . 22

3.3 Assembly Objet Representation . . . 23

3.4 Boundary Representation. . . 24

3.5 CSG representation . . . 25

3.6 Assembly sequene representation . . . 25

3.7 Mating onditions . . . 26

3.8 Roboti Cell ObjetRepresentation . . . 28

3.9 ConstraintObjet Representation . . . 30

3.10 History Objet Representation . . . 31

3.11 Data Interfae ObjetRepresentation . . . 32

3.12 Tree Node ObjetRepresentation . . . 34

4.1 Test bed Snapshoot . . . 40

4.2 Assembly and Robot . . . 40

4.3 Assembly's parts CSG representation . . . 41

4.4 Relationships between assembly parts . . . 42

4.5 One possible assemblysequene . . . 42

4.6 Example's Constraints . . . 43

4.7 Base Part's external faes and their stabilityindexes . . . 44

4.8 Step 1: StablePositionsAnalysis . . . 45

4.9 Stayout Zones . . . 46

4.10 Two FixturingSets . . . 47

4.11 Step 2: FixturingSets Analysis . . . 48

5.1 System Snapshoot. . . 50

5.2 Loading the base part into the system. . . 56

5.3 Analyzers information . . . 57

5.4 Analyzers information . . . 58

5.5 Set of analyzers and analysis progress window fortest 1 . . . 59

5.6 Set of analyzers and analysis progress window fortest 2 . . . 59

5.8 Analysisprogress windowfor test 3 . . . 61

5.9 Analysisprogress windowfor test 4 . . . 61

5.10 System messages and History reord windows for test 3 . . . 62

Introdution

Manufaturing enterprises have always faed the hallenge of dereasing the time

in-terval between produt oneption and rst prodution. In today's world it is vital

beause nowdays enterprises had to ompete in a global market that inludes

om-panies from all around the globe [Erkes 96℄ . Moreover, almost all ompanies rely in

state-of-the-art tehnology tohandle user requests assoonas possible [Jain 01℄.

Due to historial reasons, ompanies plae design and manufaturing funtions

intodistint departments [Gupta 97℄. Therefore, the proess of bringing a produt to

market involvesseveral iterationsbetween the design andmanufaturingstas. These

iterationsare time-onsumingandthus onlyafew designalternativesan be analyzed

in order to satisfy the turn-around time onstraint, limiting the quality of the nal

produt.

It has been proved that signiant savings, both in time and money, an be

ob-tained by the abilityto make hanges during the earlyphases of design [Whitney 90℄.

This savings ould be obtained beause the ost of making design hanges when the

produt development yle has started inreases quikly with time. This fathas lead

tothedevelopmentofanumberofmethodologiesandsoftware systemstailoredtogive

designers toolsto analyze manufaturability during the design stage [Priest 01℄.

Amongallmanufaturingdomains,assemblyofeletro-mehanialdeviesisavery

important one beause a lot of the produts made world wide are eletro-mehanial

devies whih require assembly operations. Moreover, even when assembly aounts

for typially 10% to 15% of the ost of goods sold, it an aount for a great deal of

the hiddenost, around 80% inindustries like airraft [Whitney 95℄.

On the other hand, the urrent trend of onstant produt hanges makes exible

manufaturing very appealing. One way to obtain exibility is through the use of

robots, so it isvery ommontond them onmodern fatories.

Two dierent approahes ould be taken for testing the manufaturability of a

given design. One is to use metris based on dierent fators, like number of

oper-ations, omplexity of the involved operations, et. The other one is to simulate the

manufaturingproess toseeif itisfatibletobuildthedesignwithouthavingtobuild

a physialmok-up. In the ase ofroboti assembly of eletro-mehanialdevies, the

toperform the analysis [Choi 00℄.

In order to test if a given design ould be manufatured by a spei roboti ell,

designers must answer a number of questions about sequening, stability, xturing,

grasping, motion planning and tool aessibility. Typially, designers have to answer

thesequestionsbythemselveswithoutthe helpofany tool. Insome ases,the answers

an not begiven until a prototype is atually tested,with the onsequent lostof time

and money if the test isunsuessful.

Although several tools have been developed for omputing some of the answers

need by designers, they have been developed in an isolated fashion making hard the

integrationoftheirresults. Eahtoolusesitsownobjetmodels(whihhighlightsome

partiular analysis features), sets of onstraints, sale fators, and base units (inhes,

mm, et.) leadingtoinompatibilityproblems when designers havetohain them, i.e.

tousetheoutputfromonetoolastheinputforanotherone. Forinstane, ifadesigner

wants to hain Mattikalli and Khosla system [Mattikalli89℄ with Brost and Goldberg

system [Brost96℄, he/she must obtain basi geometry information from the assembly

modeldeveloped inACIS, for ommuniating both systems.

Unfortunately,these problems makedesigners would ratheranswertheir questions

empirially,one by one, and thus a system that integrates that tools is need. Suh a

systemwillrelievedesigners fromthe integrationburden allowingthemtofousonthe

reativeaspets of theirjobs.

The systems desribed in [Thomas 01℄ and [Gupta 01℄ are good examples of the

eorts made toreate automatirobot programmingenvironments and assembly

sim-ulatorsrespetively. Thereare alsoommerialsoftwaresystems forsimulatingroboti

ells, like the one depited by [Ahrens 02℄. But these systems ould not analyze all

aspets of an assembly beause they make some simpliations in order to ompute

allthesolutionswithoutuserguidane. Forinstane,the [Thomas 01℄systemassumes

the grasp positions of eah objet are pre-speied. Also, as these systems are losed

ones,itwillbehardtointegratethemwith othersowftaretoolsinordertodoabetter

analysis.

A generaltreatmentof the integration issues would lettoreatea system inwhih

assembly analysis toolsould behained together by the designer, inorderto perform

manufaturability analysis of a given assembly design for a spei roboti ell. A

system like this will help manufaturing enterprises to speed up their turn-around

times and to improve the quality of their nal produts by allowing designers analyze

several designalternativesin less time.

1.1 Problem Statement

Analysis of assembly manufaturability is not an easy task; even for the simplied

assembly and the 4 D.O.F robotshown ongure 1.1, several problems must besolved

in orderto say if the robot an assemble it:

(a) Simplied disk driveassembly

(b)SeikoRobot

Figure 1.1: Assembly and Robot

Stability: To nd aset of orientationsfor eah piee of the assembly, so they an be

positionedinthe working table withoutfallingdown.

Grasping: To nd a set of grasping points on eah piee, so they an be grasped by

the gripper withoutfallingdown.

Fixturing: To nd a set of xtures for eah piee, so they an remain on an stable

positionin the working table while the robotis making the assembly.

Motion planning: To nd free trajetories for eah assembly step, so the robot an

reah allthe piees.

Tool aesibility: Tondout ifthereisenoughroomoneahpieetoguarantee tool

aessibility.

Eah one of these problems onstitutes an ative researh area by itself, and to

automatially answer them is omputationally expensive. For instane, in order to

synthesize a grasp or axture, a set of simultaneous linear equations must be solved;

typially,there are innitesolutionsand onlysome of them must behosen.

Moreover, there are alsoseveral issuesthat must besolved in orderto integrateall

the answers. Adetailedassemblyplanisalistoftheassemblystepswithspeiations

abouthowtoplaethepiees,howtogripthemandhowtoxturethemalongwiththe

trajetories and the end-eetor hanges the robot must follow tobuild the assembly.

Togenerateafeasible detailedplan, individualanswers must beseleted insuhaway

that no one violates any of the onstraints imposed by previous solutions.

Toreateafullyautomatedassemblymanufaturabilityanalysissystemthatworks

foranykindofassemblyandanykindofrobotiellisoutofreahforatualtehnology.

Abetterideaistobuildasystemthathelpsdesignerstointegratesoftwaretools,whih

This researh desribes the design and implementation of a modular

omputer-aided framework whihenables the integration of software tools for manufaturability

analysisofrobot-madeassembliesofeletro-mehanialdeviesduringthedesignstage.

The integration of stability analysis, grasping and xturing tools was taken as a

working example;itisassumed thatafeasibleassemblysequene isgivenasinput,but

an assembly sequener ould be added as atoolif the designer wants totest dierent

sequenes.

1.2 Proposed Solution

The general problem of integrating software tools developed by dierent people had

been addressed by several works like [Yang 00, Harvey 97, Bao 96, Fromme93℄. All

of thempropose omputer frameworks that helpprofessionalprogrammersin building

new omputer systems by meansof hainingpre-existent software tools.

But designers are not professional programmers, and they do not want to build a

system; they need asystem whihletthem speifyinteratively aset of software tools

to be alled, the assembly problem to be analyzed by the tools, and the information

interhange between the tools in order to nd a set of detailed plans to build the

assembly, oratleast some advie about the probable auses of failureif noplan ould

befound. Thedesign anddevelopmentof suh asystem isthe maingoalofthis thesis.

Eah one of the speied tools will produe several alternatives, and eah one of

the alternatives must be tested to see if they are oherent with the requirements of

the other tools. Therefore, the system must beapable of integrating the information

handled byeahtool,maintainingthe ohereneoftheinformation,andautomatially

transforming the information.

Evenwhenitseemsthestatedproblemismoreatehnialproblemthanasienti

one, in orderto solve itsome importantissues were addressed:

Is there a onsistent domain ontology that ould enable the ommuniation

be-tween software toolsaimed atassembly manufaturability analysis?

How ould that ontologybe formalized?

Is thereageneralway toletdesigners speifyalls tothird-party software tools?

Isthereageneralwaytoletdesigners speifythedatainterhangebetween those

tools?

Could the toolsbeaessed via Internet?

Could the toolsbewritten inany omputer language?

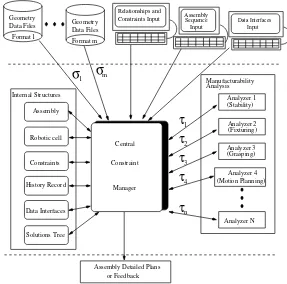

Figure1.2depitsanoverviewoftheproposedarhiteture. Asitanbeseen,itisa

modulararhiteture and onsist of three key elements: a entral onstraintmanager,

internal strutures and a set of speialized analyzers (software tools). The entral

onstraintmanagermakesrequests tothe speializedanalyzersinordertobuildatree

with all the feasible plans of assembly (solutions tree). The analyzers at as servers

apable of solving problems in grasping, stability,xturing, et. The order for alling

the analyzers and thedata ows between themand the internalstrutures isprovided

by the designer and stored in the data interfaes struture. The entral onstraint

manageralsoreordseahalltothe servers, andtheir resultsin aninternalstruture

(history reord) inorder to beapable of trae bak any oherene problem.

In a typial session the user rst feeds the system with assembly and roboti ell

desriptions. These desriptions inlude geometri data, relationships between parts,

onstraints and a feasible assembly sequene. As laimed previously, an assembly

se-quener ould be added as one of the analyzers if dierent sequenes will be tested.

Geometri dataould berestored fromles writtenin any format, as long as a

trans-formationmapping('s)between thatformatandtheinternalstruturesofthesystem

isprovided. Constraintsaredened by booleanevaluationproedures thatreturntrue

if the onstraint holds for a partiular objet orlist of objets, orfalse otherwise.

Later,theuserspeiestheorderofanalysisandthedatainterfaesbetweenthe

in-volvedproesses. Ablakboxintegrationapproahisusedallowingtheanalyzerstobe

implemented inanyomputer languageaslongasthey usethe standard input/output

system toreadvariablesandoutputresults. Sokets areusedtoommuniatewiththe

analyzers, so they ould be run in any omputer plugged to the World-Wide Web at

any loationaround the world. The entral onstraintmanager llsitsinternal

stru-tures with the information provided by the user and start to generate allthe feasible

assemblyplansthatagreewiththeseleted sequene ofassembly, usingtheonstraints

to prune the results and thusto reduethe time toompute all the feasible solutions.

Foreahstep of the sequene, the entralonstraintmanageralls the appropriate

speialized analysis proess, hek the onstraints,disardthe resultsthat violate any

onstraint, addthe validresultstothe solutions tree, andgenerate a newentry onthe

history reord to registerthe proess alled and the resultsobtained fromthat all. If

it is the ase that nofeasible planremains inthe solutions tree,the entral onstraint

manager informs the user, and allows himtosee the history reords totrae bak the

problem.

Itisworthtomention thateven whenthe proposed frameworkarhiteture

resem-bles a blakboard arhiteture [Newell 62, White 90,Nii 86, Hewett 97,Koh 00℄they

dier mainlyinthe following points:

Blakboard systems are losedsystems inthe sense thatmodyng the system to

add or replae tools requieres a programming eort. The proposed framework

is an open system beause it is designed to add or replae tools dynamially at

run-time by letting the user speify physial loation and I/O requirements of

1

σ

Format 1

Geometry

Data Files

Format m

Geometry

Data Files

σ

m

Relationships and

Constraints Input

Assembly

Sequence

Input

Data Interfaces

Input

Manufacturability

Analysis

(Stability)

Analyzer 1

(Fixturing)

Analyzer 2

(Grasping)

Analyzer 3

Analyzer 4

(Motion Planning)

Analyzer N

Assembly

Robotic cell

Constraints

Data Interfaces

Solutions Tree

Central

Constraint

Manager

τ

1

τ

2

τ

3

τ

4

τ

n

Assembly Detailed Plans

or Feedback

History Record

Internal Structures

Figure 1.2: Framework Arhiteture Overview: 's and 's represent transformation

mappings between geometry formatsand data interfaes respetively

analysis of assemblies, inludeonly high levelplanners whih an not be usedto

generate detailed assembly plans of any assembly done inany roboti ell. This

is due mainly beause to automatially handle the omputational omplexity

involved is out ofreahfor atualtehnology. The proposedframeworkdoes not

try to fully automate manufaturability analysis of assemblies, it is designed to

give designers a systemati way of searhing a verylarge solution spae, sothey

ouldtakeintoaountabiggernumberofsolutionsthanthenumberofsolutions

they atually ould handle.

1.3 Main Contributions

The majorontributions of this researh an beharaterizedas follows:

Denition and formal speiation of a entral assembly-oriented data model

wih inludes information about assemblies, roboti ells and onstraints. The

data modelis basedonaomprehensivedomainontologythat enablesthe

inter-operation of manufaturability analysis software tools by managing information

[image:21.612.145.432.97.381.2]mehanisms. Ablakboxintegrationapproahisusedallowingthesoftwaretools

to be implemented in any omputer language as long as they use the standard

input/output system to read variables and output results. Constraint

manage-mentis used asaommuniationmehanismbetween the tools. The integration

of their solutions is made by testing eah solution generated to keep oherene

with therequirementsofallthe tools. Sokets areused toommuniatewiththe

software tools,so they ouldberun inanyomputer pluggedtotheWorld-Wide

Web at any loation aroundthe world.

1.4 Organization

Chapter 2 provides bakground information, it inludes setions on Assembly Data

Modelling,AssemblyPlanning,Graspingand Fixturing,Software Integration Systems

and Blakboard Systems. Chapter 3 desribes the proposed framework. Chapter 4

presents the testbed built and aworking example. Chapter 5 provides adesriptionof

the omputer implementationof the framework anduses the previous dened working

example to test it. Finally,Chapter 6 summarizes the motivationof this researh, the

Related Work

Asstatedintheintrodution,thegoalof thisworkistobuildaomputer-aided

frame-work whih enables the integration of software tools for manufaturability analysis of

robot-made assemblies.

The software tools will answer a number of questions about sequening, stability,

xturing,grasping, motionplanningandtoolaessibility. Eahoneofthesequestions

onstitutes anativeresearharea by itself,andtoautomatiallyanswerthemis

om-putationallyexpensive. Reif showed motion planningtobe PSPACE-hard, Natarajan

and Wolterproved theassemblysequening problemwithanarbitrarynumberofparts

to be alsoPSPACE-hard, and itremainsPSPACE-hard whenthe partsare limited to

a onstant number of verties [Reif 87, Natarajan88, Wolter 88℄. For synthesizing a

grasp or a xture, a set of simultaneous linear equations must be solved. Typially,

there are innitesolutionsand onlysome of them must behosen.

The framework is designed in suh a way designers ould guide the analysis, and

eventest dierentversionsofatool. Theintegrationofstabilityanalysis,graspingand

xturing toolswas taken asa working example;it isassumed thata feasible assembly

sequene is given as input, but anassembly sequener ould be added as a tool if the

designer wants totest dierent sequenes.

Inthe followingsetions the work alreadydone inassemblydata modeling,

assem-blyplanning,graspingandxturingandsoftware integrationsystemsispresented. For

a surveyonmotionplanning, readersare referredto[Latombe93,Hwang 92℄. For

ref-erenes abouttoolaessibility,[Wilson 96℄ouldbeonsulted. Asetiononblakboard

systems isalsoinluded tomake lear the dierenes between them and the proposed

framework.

2.1 Assembly Data Modelling

Astheframeworkwillenabletheintegrationofsoftwaretoolsaimedtoassembly

manu-faturabilityanalysis,itisimportanttondoutasharedlanguage,ordomainontology,

whih lets the tools toommuniatebetween eahother.

Robotis researhers were the rst to model assemblies, and their models

[Whitney 77℄.

Later, assemblies wererepresented by aseriesofgeometri modelsforeah

individ-ualpart,andalistoftherelativepositionandorientationofeahindividualpartinthe

nalassembledonguration[Lee 85,Lin90,Minami 95℄. This approahisommonly

used by most of the works related toassemblies, and it ould be onsidered the basi

model.

In[Whitney 95℄,aomprehensivelistofaspetsthatmustbemodelforrepresenting

assemblies is given. But not an spei model is proposed beause it is laimed that

more work is needed to really understand assemblies and their models. Nevertheless,

this list isvery useful when trying to dobetter models.

Adetailedliteraturereviewabout assemblyrepresentationsispresentedbyMasle.

He onludes that the basi model remains essentially the same from one author to

another. He alsoproposes anew modelin whihthe assemblystates (or steps)are an

integral part of the produt model[Masle 99℄.

More reent works add some features tothe basi modelin order toperform

intel-ligent simulations. For instane, [Gupta 01℄ presents an assembly representation that

allows artiulation handling.

2.2 Assembly Planning

As stated in [Wolter 92℄: \An assembly planner is a program designed to generate

high-level plans for the manufature of mehanial assemblies". Assembly planners

ould be ategorized by the approah taken togenerate the plans. The most ommon

approahes are reviewed inthe next subsetions.

2.2.1 General planners

The Artiial Intelligene (AI) ommunity has always been interested inthe

develop-mentofdomain-independentplanners. The lassialAIplanningproblemisdenedin

asimpleformastheproblemofsimultaneouslyahievingatthenaltimeseveralgoals

alled \subgoals". A planner determines the order whih makes the goal ahievable.

In some ases the goal state an be ahieved if the subgoalsare ahieved in a ertain

order (linear planning problem). However, in other ases even thought the goal state

isvalidand ahievable thereis noorderingonthe onjuted subgoalsthat an ahieve

the goal state (non-linear planning problem). Theoretially, the underlying planning

method inthese systems isdedution.

STRIPS was one of the rst pratial planners wih fous in the onjutive goal

problem [Fikes 71℄. It was based on the linearity assumption and ould solve only

problems where the onjution of several subgoals ould be ahieved by ordering the

subgoal ahievement proesses. NOAH and SIPE are also representative examples of

thesedomain-independentplanners [Saerdoti 77,Wilkins 84℄. In STRIPSandNOAH

Buildisanad-hoplannerforbuildingspeiedstruturesoutofsimpletoybloks,

the planning is done in a modeled 3D-spae in whih bloks of various shapes and

sizes an be represented in any orientation and loation; it inorporates geometrial

tests for inter-objet ontat and ollision,and for stability involving fritional fores

[Fahlman 74℄.

Another AI approah is presented by Bakstrom; he uses rst order prediate

al-ulus for geometri reasoning about assembly proesses. His work is restrited to a

2D-world and no planner is presented, just an algorithm for verifying assembly steps

[Bakstrom 87℄.

Unfortunately, this kind of planners do not reason about geometri onstraints in

the way needed by anassemblyplannerbeausealmostallmakeuse ofaveryabstrat

geometri desription of the objetsand their relationsexpressed inlogial notation.

2.2.2 Sequeners

Assemblyplanningmayalsobeviewedasageneralmotionplanningproblem,butthat

makes extremly hard to handle it [Latombe 93℄. This fat has lead to a simpler

sub-problem denition known as assembly sequene planning in whih only the geometri

onstrains arisingfromtheassemblyitselfare onsideredassumingthattheparts

om-posing the assembly are free-ying objets, i.e. the manipulation system (e.g. robots)

is ignored.

Sequene editors

The early assembly sequeners were mainly sequene editors in whih geometri

rea-soning was supplied by a human who answers questions asked by the systems, whih

in turn generate the assembly sequene from the answers.

Thesystem developed by Bourjaultrepresentsthe rst step towards anautomated

assembly planner. That system asks a human expert arefully onstruted yes-no

questions, and the preedene relationships between onnetions or between logial

ombinationsofonnetionsareinferredfromtheanswers[Bourjault 84℄. DeFazioand

Withney present an improvement on the number of questions asked to the user. For

simple ases, these approahes take advantage of the expert intuitive understanding

of parts relations and feasibility of operations. Unfortunately, the orretness and

ompleteness of the algorithms used in both systems have not been proved and it

is neesary to have those proofs in order to guarantee that the resulting preedene

relations are satised by all the feasible assembly sequenes and only by the feasible

ones; besides,forlargeassemblies,itisverydiÆultforahumanexpert togiveorret

answers [De Fazio 87℄ .

Generate-and-test sequeners

questionstohektheirfeasibility,andsomegeometrireasoningmodulesforanswering

these questions.

Geometri omputations are repeated several times making relatively inneient

this approah tothe pointthat itis appliable onlyto assemblies with few parts.

Homem de Mello and Sanderson present a orret and omplete algorithmfor the

generationof mehanial assemblysequenes. They transformtheproblemof

generat-ing assembly sequenes into the problem of generating disassembly ones. Assemblies

are represented through arelational modelthat inludesparts, ontats, attahments

and a set of relationships between them [Homem de Mello88℄ . Galloand Pallottino

presents omputationallyeÆient hyper-graph algorithmsto solve the assembly

prob-lemas dened by Homemde Melloand Sanderson [Gallo 92℄.

Frommherz and Hornberger also use the disassembly tehnique, but they use only

geometrial informationabout eah part of the assembly as input. Their outputis in

the form of preedene graphs[Frommherz 88℄.

Mattikalli and Khosla developed a system apable of determining assembly

se-quenesinvolvingrotationalandtranslationalonstraints. They userelativelydetailed

3D models as input [Mattikalli89℄.

Santohi and Dini desribe FLAPS (Flexible Assembly Planning System), a

om-pletesystem forthe planningofassemblyoperations. A ompromisebetween the fully

automated and the interative approah is used; they ask the user information about

preedenerules,aessibilityonstraintsandelementsthatannotbedisassembledby

simple translation. The system ismade of four modules,only the rst one isreported

as fully implemented: sequene generation, assembly operation planning, seletion of

the best assembly sequene, and o-lineprogrammingof mahines [Santohi 92℄.

2.2.3 Other approahes

Wilson and Latombe redued the omplexity of generating assembly algortihms for

3D models to polynomial bonds through the use of non-diretional bloking graphs

(NDBG), whihdesribes the potentialinterations amongparts in polynomialspae.

Their onstrution derives from the observation that innite families of motions an

be partitioned into nite olletions of subsets suh that the interferenes among the

parts are onstant over every subset. One omputed, the NDBG an be exploited

for a variety of purposes, inludingthe polynomial generation of assembly algorithms

[Wilson 94℄.

Mostoftheaboveplanners haveproblems whendealingwith realworldassemblies,

Chakrabarty and Wolter propose a hierarhial approah to lessen the ombinatorial

problems in realisti assemblies. They view an assembly as a hierarhy of standard

strutures and merge partial plans for these strutures to derive a plan for the whole

assembly. Their system take advantage of the fatthat ertain typial ways in whih

setsofpartsareombinedreurveryoften,notonlyinagivenassemblybutindierent

assemblies aswell. Theombinatorialproblems arelessened beausetheplans for

reasoning rst about geometri properties and then, about non-geometri onstraints [Lin 93℄.

Kaufman et. al have developed another omplete system, Arhimedes 2. They

relyonuserinputinsteadofusing sophistiatedfeature-reognitionsoftware,and have

implemented a fastollision detetion algorithm. Thisalgorithmuses agraphi

work-station hardware Z buer to quikly nd ollisions between omplex faeted models.

Their system haveomputed sequenes for assemblies from both industryand

govern-ment [Kaufman96℄.

Other approahes taken to solve the assembly planning problem inlude the use

of Petri Nets [Zhang89, Astuti 94, Caselli 95℄, ase-based reasoning [Pu 92℄, state

matrix representation [Noorhosseini 95℄, otree representation [Dini95℄, and geneti

algorithms[Bonneville 95℄.

AnewversionofArhimedessystem, Arhimedes4isdesribed in[Calton99℄. The

newsystemtakesasinputaCADmodel,automatiallyomputespart-to-partontats

and ollision-free insertion motions using the NDBG approah, and the fast ollision

detetion algorithmto generate feasible sequenes that are ranked by a user-speied

quality metri(speiedintermsofostsfor standardassemblyproesssteps likepart

insertion, fastening,et.). Italsohasaninterativeuserinterfaewhihletstheuserto

systematially explore the spae of feasible sequenes. Then the user ould add more

onstraints, like requering ertain parts to be assembled rst and ask the system to

generate again the feasible sequenes. Five modules were added to handle ergonomi

and ostanalysisanddenitionoftool,graspingandxturingonstraints. Thesystem

hasbeentestedover100assembliesandtheminimumandmaximumreportedplanning

timesare4seondsand6hoursrespetively. Also,usershavereporteda75%redution

in time shedules, and 25% redution inprototyping fabriation.

2.3 Grasping and Fixturing

Grasping and xturing are losely related. Both of them pursue the same goal: tox

an objet kinematiallyby meansof asuitable set of ontats. Thus, it is logialthat

researh in one area benets the other and vie versa.

Formally, the ation of grasping an objet an be dened as the plaement of the

gripper relative to the objet, and it is haraterized by a set of ontats alled a

grasp. Grasp planningonsists in hoosing the loation,the type (pointwith frition,

soft nger, et.) and appliedfores and torques.

The planning must be done in suh a way there is a ollision free trajetory to

reah every ontat, the objets are seurely grasped and holded, the task ould be

performed,andthereisawaytodroptheobjetinaknownonguration. Dealingwith

all these onditions is intratable, so grasp planning is usually split into overlapping

subproblems.

Two importantoneptsinthe areaarethose of\formlosure"and\fore losure"

A \fore losure" grasp is a grasp where the maintenane of the body's equilibrium

requires the appliation of anexternally applied wrenh [Trinkle92℄.

An extensive survey onxturingand graspingan befound in[Pertin-Troaz 89℄.

A review of gripperdesigns, ontrolmethodsand grasp ongurations is presented by

[Boubekri 02℄.

Reuleauxwasthersttoworkthroughtheunderstandingofgraspingandxturing.

On his work he showed that four higher-pair ontats were requiered to prevent all

motion fora rigid laminarestrited towork in aplane [Reuleaux 76℄.

Somo alsowas apioneeronthis area, and he stablished that aminimumof seven

pointontatsareneessary forformlosureofanarbitrary3Drigidbody[Somo 00℄.

The rst works on human grasping are due to Napier. In those works, human

grasping is studied from anatomial and funtional points of view, and two patterns

forprehensilemovementsareproposed: the powergraspandthe preisiongrasp. Also,

one non-prehensile postureis dened: the hook grasp [Napier56, Napier 62℄.

Napier studies stimulated the further development of dextrous robot hands, like

the tri-ngered hand with adjustable rigidity one developed by Hanafusa and Asada.

They alsodeveloped anheuristiforobtainingastablegrasp fromasensoryprolefor

theirhand,and basedthatheuristionthesearhforaloalminimumofthe potential

funtion with the enter of the hand near the entroid of the prole [Hanafusa 77a,

Hanafusa 77b℄.

Lakshminarayanawasthersttodesribeanapproahtosynthesizingform-losure

grasps of 3D fritionless objets; he also showed that seven ngers are neessary to

ahieve fore-losure of a 3D objet [Lakshminarayana 78℄.

Abel,HolzmannandMCarthydetailanalgorithmtondaurveofpossiblegrasps

fromasetofequilibriumequationsparametrizedbythemagnitudoftheappliedfores;

theyalsointroduedtheoneptofinipientrigidbodyslipandshowedhowtoompute

the frition fores assoiated with a grasping[Abel 85, Holzmann 85℄.

Mason and Salisburygave onditionsforomplete restraintof anobjetby agrasp

in terms of internal fore. Their work was used for the design of hands that grasp

seurely and for generalized graspingwhen the motion of the objet to manipulate is

not ompletely onstrainedby the gripper, partiularlywhen pushing[Mason 85℄.

Cutkosky developed a proedure for analyzingthe grasp properties of stiness and

resistane to stipping and introdue the onept of innitesimal stability in order to

ompare grasps [Cutkoski 85℄.

NguyenusedReuleauxideastodevelopalgorithmstosynthesizeform-losuregrasps

of given rigid laminaand 3D objets. Theseworks alsopresentbinary tests indiating

the existene ornon existeneof form losure[Nguyen 86℄.

Ji and Roth gave onditions for equilibrium and fore losure in the three nger

ase [Ji87℄. Nguyen presented a geometri test for two-nger fore-losure grasps on

both polygonal and polyhedralobjets [Nguyen 88℄.

Markenso, Ni and Papadimitriou proved that any non exeptional fritionless

objet anbegrasped informlosurewith onlyseven ontat points[Markenso 90℄.

Lately, systems for omputer-aided planning and analysis of xture set up, and

omputer-aided xture design veriation are disussed in [Shirinzadeh 02, Kang 02℄

respetively.

Also a new tehnique for workpiee retention during mahine proessing based on

eletrorheologial uids ispresented by [Monkman01℄.

2.4 Software Integration Systems

In the eld of Software Engineering, reuse of ode has been always a goal to improve

system prodution. As early as the eighties, work had been reported for setting the

harateristisof integrable software tools[Nejmeh 89℄.

Sine then a number of software integration frameworks oer a reusable faility

for the integration of software tools; typially they provide at least a ommuniation

mehanism,adatastorageandaontrolfailitytobuildnewsystemsbasedonalready

devlopedones. Asurveyaboutthiskindofenvironmentsouldbefoundin[Harvey 93℄.

Among others, the works of [Yang 00, Harvey 97, Bao 96, Fromme 93℄ are

repre-sentativesof the urrenttrends inthearea. Allof themproposeomputer frameworks

that help professional programmers in building new omputer systems by means of

hainingpre-existent software tools.

But designers are not professional programmers, and they do not want to build a

system; they need a systemwhihletthem speify interativelyaset of software tools

to be alled, the assembly problem to be analyzed by the tools, and the information

interhange between the tools in order to nd a set of detailed plans to build the

assembly, orat least someadvie about the probable auses offailureif no plan ould

befound.

The work desribed in[Weatherill99℄allows the integration of arbitraryomputer

appliation software into an environment to provide a multi-disiplinary engineering

analysis apability within one unied omputational framework. Unfortunately, it

works only forunstrutured gridappliations and itdoesnot havethe failityto

inte-grate several answers.

Otherintegrationeortshad fousedintodevelopingsystemsthat ouldplan,

eval-uate and exeute programs for industrial robots. In order to do that, the systems

must synthesize a robot spei program from a sequene of tasks, must deide how

to grasp and xture the parts, and whih are the robotmotions needed toaomplish

the task athand. Thisresearh area isknown asTask-Level RobotProgramming.The

deisions took by these systems are interdependent and propagate aross eah other.

For instane, the hoie of a grasping onguration determines what motions of the

robotare requiredtopositionthe part. So, onstraints mustbemonitoredarefullyto

ensure that the seleted optionssatisfy all the requirements.

The rst attempt to develop suh a system was done by [Ernst 61℄. Sine then,

a number of systems and languages have been proposed: the Stanford Hand-Eye

[Lozano-Perez 85℄,theCornellRobotSystem[Campbell85℄,Handey[Lozano-Perez 89℄,

SPAR [Huthinson 90℄and IRAS [Tung 94℄ amongothers.

Most of these systems were not implemented at all, or were ustom designed and

tailored to very spei tasks in order to deal with the omputational omplexity

involved when trying tointegrateall the omputationsneedfor generatinga omplete

system. Forinstane,the CornellRobotSystem,Handey,SPARandIRAS arelimited

primarily topik-and-plae operations.

TheArhimedessystems[Kaufman96,Calton99℄gobeyondpik-and-plae

assem-bly,but they produe ode for a spei work-ell.

Carrikerworkalsogoesbeyondpik-and-plaeassemblyby theuse ofanextensible

frameworkof modular planners, modeling systems and software tools. His system an

generate ode for dierent work-ells, but his grasping and xturing algorithms are

restrited to spei xtures and grippers. Also, it is not lear from his work how to

replae one planner by a better one, or how to add new planners in order to handle

dierent kindsof tools. He also does not take into aount mehanisms for providing

feedbak tothe designers [Carriker 95℄.

Thomas system is useful for diferent roboti ells, beause it uses a arefully

de-signed library of skill primitives, but itassumes the grasp positions of eahobjet are

pre-speied [Thomas 01℄.

2.5 Blakboard systems

Blakboard systems use a group of ooperating knowledge-based systems (knowledge

soures)whihommuniatewitheahotherbysharinginformationonaommondata

struture alled a blakboard. Newell oined the term blakboard by analogy with a

physialblakboardinwhihooperatingworkers ouldaddordeleteinformationwhile

solving a problem[Newell 62℄. The blakboard must be leaned from time to time to

prevent luttering. They an be applied to various types of problems, partiularly

those where sub-problems require nospei order of solution. They are alsosuitable

for problems where multiple lines of reasoning exist[White 90℄.

The ontrol strategy used by blakboard systems is termed opportunisti beause

eah knowledge system monitors the blakboard and ativates itself based on the

so-lutionstate represented by the blakboard. Formonitoring theblakboard,knowledge

systems must see everything onthe blakboard atall times and must write their

on-lusions withoutgettingin the way of other knowledge systems [Nii86℄.

The basiexeutionyle ofany blakboardsystem has threemainphases: agenda

maintenane,sheduling,andknowledgesoureexeution. Tomaintaintheagenda

up-to-datetwolistsarekept,oneisthetriggeredagendawhihliststheknowledgesoures

alreadytriggeredbysomeevents,theotheroneistheexeutableagendawhihliststhe

knowledge soures ready for exeution. The sheduling is done by seleting the best

knowledge soure available for exeution in eah yle, based on ontrol knowledge.

onditions determinewhetherthe knowledgesoureisexeutable, obviationonditions

indiate whih knowledge soures must be removed from the agenda and be

perma-nently disarded, ontrol knowledge let the system to rank the knowledge soures in

the exeutionagenda, and selet the best one of them [Hewett 97℄.

Trigger onditions, preonditions for exeution, obviation onditions and ontrol

knowledge are appliation-spei and must be enoded by someone, usually a

sys-tem integrator with some experiene in the appliation and in knowledge modeling

[Lander 96℄.

Commerialavailable high-performane blakboardtoolkits,suh asGBBorKPM

from Knwoledge Tehnologies International, let system integrators to develop

blak-board systems whih ombine a number of analysis tools. However, the developed

systems are losed systems beause they are not designed for hanging dynamially

the set of knowledgesoures whihare involved; toadd or replaeany tool,the whole

environment must be at least reompiled. Also, any tool that was not speially

developed as part of the system must be wrapped in an enapsulation shell in order

to anhor it into the system's infraestruture [Lander96℄. In that sense, blakboard

systems are similarto generalsoftware integration systems disused earlier.

Anumberof blakboardsystems had been developedtoaidinthe areaofrobotis.

Mainly, they had been used to implement ontrol approahes for oordinating

au-tonomous robots[Lisano 95, Oello92, Harmon 86,Bzzyky 01℄ orto implement

in-telligentontrolstrategies for a single robot[Ananthanarayanan 92℄.

Additionally, asystem for exible assembly ooperative planningwas proposed by

[Lee 90℄. This system oordinate a number of intelligent agents aimed to generate

assemblyplans. Ituses asinputanobjetmodelwhihintegrates basi informationof

parts and liasons between the parts. It is similar to [Chakrabarty 94℄ beause it also

proposes ahierarhial approahtoexploit paralellism. Anassemblyost isomputed

in order toselet assemblies with minimalost.

In general terms, blakboard systems had been eetive for high level planning,

like proess planning, supply hain planning and prodution shedule [Laliberty 96,

Sadeh 99℄. Also,they work wellinevent-data proessingofexperimentalsetupswhih

are outside ofhuman ontroland whih produesdata atunknown timepointsand in

unknown numbers [Koh 00℄.

High level planning is not apable of reasoning about geometri onstraints, in

the way needed by manufaturabilityanalysis ofassemblies, beause most of the time

it uses abstrat geometri desriptions of the assembly and the roboti ell. Even

when detailed geometri desriptions are used in some points of the planning, to

au-tomatiallyhandlethe omputationalomplexity involved whentrying touse detailed

geometri desriptions all the time isout of reah for atual tehnology. On the other

hand, manufatuarbilityanalysis ofassemblies involvesfairlystraighforward sequenes

of ativities whihare appliedto aomplish spei goals, and this kind of sequenes

are diÆulttostruture appropriately with opportunisti ontrol.

Theframeworkproposed by thisthesishas threekeyelements: aentralonstraint

systems and some ontrolstrategy for oordinating those systems.

Nevertheless, the proposed framework diers from blakboard systems in the

fol-lowing points:

Blakboardsystems are losed systemsin the sensethat modyng the systemto

add or replae tools requieres a programming eort. The proposed framework

is an open system beause it is designed toadd or replae tools dynamially at

run-time by letting the user speify physial loation and I/O requirements of

eahtoolused.

Blakboard systems developed until now, in areas related to manufatuarbility

analysis of assemblies, inludeonly high levelplanners whih an not be usedto

generate detailed assembly plans of any assembly done inany roboti ell. This

is due mainly beause to automatially handle the omputational omplexity

involved is out ofreahfor atualtehnology. The proposedframeworkdoes not

try to fully automate manufaturability analysis of assemblies, it is designed to

give the designer asystemati way of searhing a very large solution spae.

2.6 Summary

This hapter has presented the state of the art in the areas related to this researh:

assembly data modeling, assembly planning, graspingand xturing and software

inte-gration systems. The review of previous work for eah area was done fousing in the

aspetsthat needtobesolvedinordertobuild theframeworkproposed bythis thesis.

From this review it follows that:

There isnoformal assembly data modelthat inludesinformationabout

assem-blies, roboti ells and onstraints. There is a lak of a shared language for

ommuniating toolsfor assembly manufaturability analysis.

Atual planningsystems were developed as losedsystems so itisno possible to

add third-party software tothem for doing better analysis.

Even when general software integration frameworks let make new systems by

mixing third-party software, they are too general to be used by designers and

they are not apableof hanginginterativelythe mixed software atrun time.

Task-levelrobotprogrammingsystemsalsohadbeendevelopedaslosedsystems.

Asetiononblakboardsystemswasalsoinludedtomakelearthedierenesbetween

them andthe proposed framework. Mainly, the framework isdierentbeause itisan

open system whih ould integrate third-party software, and does not try to fully

Framework

As statedearlier,the maingoalofthis researhis toshow thatitisfeasible todevelop

a modular omputer-aided framework whih enables the integration of software tools

for manufaturability analysis of robot-madeassemblies of eletro-mehanial devies

during the design stage.

Aseahone of thespeiedtoolswillprodueseveral alternatives, andeahone of

the alternativesmust betestedtosee ifthey are oherentwiththe requirementsofthe

othertools,thesystemmustbeapableofintegratingtheinformationhandledby eah

tool,maintainingtheohereneoftheinformation,andautomatiallytransformingthe

information.

To gure out some of the harateristis of suh an integrative system, a testbed

was developed to emulate the atual problems designers must fae when they deide

to use the analyisis toolsthey had at hand. The testbed isdesribed in next hapter.

Even whenitseemsthestatedproblemismoreatehnialproblemthanasienti

one, in order tosolveit some interesting issues were addressed:

Is there a onsistent domain ontology that ould enable the ommuniation

be-tween software toolsaimed at assembly manufaturabilityanalysis?

Howould that ontologybeformalized?

Is therea generalway toletdesigners speify alls tothird-party software tools?

Isthereageneralway toletdesignersspeifythe datainterhangebetweenthose

tools?

Could the tools be aessed via Internet?

Could the tools be writtenin any omputer language?

Is there a way to letdesigners prunethe solutionspae?

Could the geometry data be represented inany format?

Inthefollowingsetionsthedesriptionoftheframeworkproposed bythisresearh

3.1 Framework overview

Althoughthereisnouniversal denitionofthe termmanufaturability,itisaommon

plaetounderstanditasthe referenetothedesignharateristiswhihindiatehow

diÆultor easy the designis from manufaturing perspetive[Gupta 97℄.

Instead of proposing someindex of manufaturability, aonstrutiveapproahwas

used tosolvethis problem,i.efeasibleplansmust befound inordertoverifyif agiven

assembly design is manufaturable by a given roboti ell. If no plan ould be found,

some advie about the probable auses of failuremust begiven.

Figure 3.1 depits an overview of the proposed framework. As it an be seen, it

has a modular arhiteture and onsist of three key elements: a entral onstraint

manager, internal strutures and a set of speialized analyzers (software tools). The

entral onstraint manager makes requests to the speialized analyzers in order to

build a tree with allthe feasible plans of assembly (solutions tree). The analyzers at

as servers apable of solving problems in grasping, stability, xturing, et. The order

for alling the analyzersand the data ows between them and the internal strutures

is provided by the designer and stored in the data interfaes struture. The entral

onstraintmanageralsoreordseahalltothe servers, andtheirresultsinaninternal

struture (history reord) inorder tobeapable of trae bak any oherene problem.

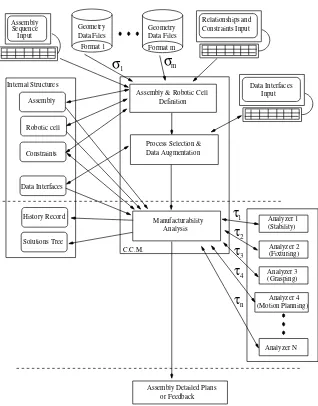

As shown in gure 3.2, in a typialsession the user rst feeds the system with

as-sembly and roboti elldesriptions. These desriptions inlude geometri data,

rela-tionshipsbetween parts,onstraintsandanassemblysequene. Aslaimedpreviously,

anassemblysequenerouldbeaddedasoneoftheanalyzersifdierentsequenes will

be tested. Geometri data ould be restored from les written in any format, as long

as a transformation mapping ( 's) between that format and the internal strutures

of the system is provided. Constraints are dened by boolean evaluation proedures

thatreturntrue ifthe onstraintholds forapartiularobjetorlistofobjets, orfalse

otherwise.

Later,theuserspeiestheorderofanalysisandthedatainterfaesbetween the

in-volvedproesses. Ablakboxintegrationapproahisusedallowingtheanalyzerstobe

implemented inany omputer languageaslong asthey use the standard input/output

systemtoreadvariablesandoutputresults. Sokets areusedtoommuniatewiththe

analyzers, so they ould be run in any omputer plugged to the World-Wide Web at

any loationaround the world. The entralonstraint managerlls itsinternal

stru-tures with the informationprovided by the user and start togenerate all the feasible

plansthat agreewiththe seleted sequene ofassembly, usingtheonstraintstoprune

the results and thus toredue the time to ompute allthe feasible solutions.

Foreah step ofthe sequene, the entralonstraint manageralls the appropriate

speialized analysis proess, heks the onstraints, disards the results that violate

any onstraint, add the valid results to the solutions tree, and generate a new entry

on the history reord to register the proess alled and the results obtained from that

all. Whenever no feasible plan remains in the solutions tree, the entral onstraint

1

σ

Format 1

Geometry

Data Files

Format m

Geometry

Data Files

σ

m

Relationships and

Constraints Input

Assembly

Sequence

Input

Data Interfaces

Input

Manufacturability

Analysis

(Stability)

Analyzer 1

(Fixturing)

Analyzer 2

(Grasping)

Analyzer 3

Analyzer 4

(Motion Planning)

Analyzer N

Assembly

Robotic cell

Constraints

Data Interfaces

Solutions Tree

Central

Constraint

Manager

τ

1

τ

2

τ

3

τ

4

τ

n

Assembly Detailed Plans

or Feedback

History Record

Internal Structures

Figure 3.1: Framework Arhiteture Overview: 'sand 's represent transformation

[image:36.612.159.476.235.555.2]Assembly & Robotic Cell

Definition

1

σ

σ

m

Assembly

Internal Structures

Solutions Tree

History Record

Data Interfaces

Robotic cell

Constraints

Process Selection &

Data Augmentation

Data Interfaces

Input

Manufacturability

Analysis

(Stability)

Analyzer 1

(Fixturing)

Analyzer 2

(Grasping)

Analyzer 3

Analyzer 4

(Motion Planning)

Analyzer N

Assembly Detailed Plans

or Feedback

1

τ

τ

2

τ

3

τ

4

τ

n

Relationships and

Constraints Input

Format 1

Geometry

Data Files

Format m

Geometry

Data Files

Assembly

Sequence

Input

C.C.M.

Figure 3.2: Framework arhiteture exeution ow for a typial session: 's and

'srepresent transformationmappings between geometry formatsand data interfaes

[image:37.612.135.453.182.588.2]Sequence

Step

Part

Id

Step

Id

Part

Mating

Part

Mating

Relation

Fixtured

Part

Id

Geometrical Descr.

Kind

Info

Volume

Gravity

Center

of

Reference Frame

Reference Frame

Assembly

Figure3.3: Assembly Objet Representation

3.2 Internal Strutures

The proposed framework must be apable of integrating the information handled by

eahtool,maintainingthe oherene ofthe information,and automatially

transform-ing the information.

Therefore,itisneessary tosetasharedlanguage,ordomainontology,

omprehen-sive enoughto handle informationfor haining proesses, storingsolutions and giving

feedbakto theuser. A omprehensiveontologyinludesallthe basionepts needed

to fully desribe the domain.

The internal strutures depited in gure 3.1 let the Central Constraint Manager

managethe domainontologyproposed by thiswork. Aentralassembly-orienteddata

modelisinludedinsidetheontology,anditisstoredin3dierentstrutures: assembly,

roboti ell, and onstraints.

The informationneeded to give feedbak tothe user isstored inthe history reord

internal struture, the information needed to use the output from one proess as the

inputfor anotherone isstoredinthedatainterfaesinternalstruture, andthe results

of the analysis are stored inthe solutions tree internalstruture.

Asstated in[Woodok 96℄, the ornerstoneof any formalsoftware development is

the onstrutionof a lear speiation. The domain ontologyis speied using the Z

notation in the following setions. Fora omplete desription of Z readers are refered

to [Woodok 96℄.

All the referene frames mentioned below are represented by 4

4-homogeneous-transform matries[Shilling 90℄.

3.2.1 Assembly

An assembly data model would ontain all the information any proess would want

to know about an assembly, but suh a database might be unmanageably large or

hard to navigate. Thus, to represent anassembly, a subset of the aspets of assembly

outlined by Whitney as neessary or useful in an assembly-oriented database were

Figure3.4: BoundaryRepresentation (BREP):asolid isdesribed asalistof verties,

edgesandfaes. Eahvertexisdenedbythreeoordinates (x,y,z), anedgeisdened

by two verties, and a fae is dened by a listof edges. Forinstane V1 is dened by

(X1,Y1,Z1), E1is dened by (V1,V6) and f1 is dened by (V1,V2,V8,V7).

sequene steps, and a referene frameto loate the assembly onthe global oordinate

system. The assembly referene frame allows the plaement of the assembly relative

tothe globaloordinate system.

Foreahpartthe usermust provideanidentier(Id),ageometridesriptionanda

refereneframe toloate the part onthe loaloordinatesystem. Eahpart referene

frameallows the plaementof parts relative tothe assembly oordinatesystem.

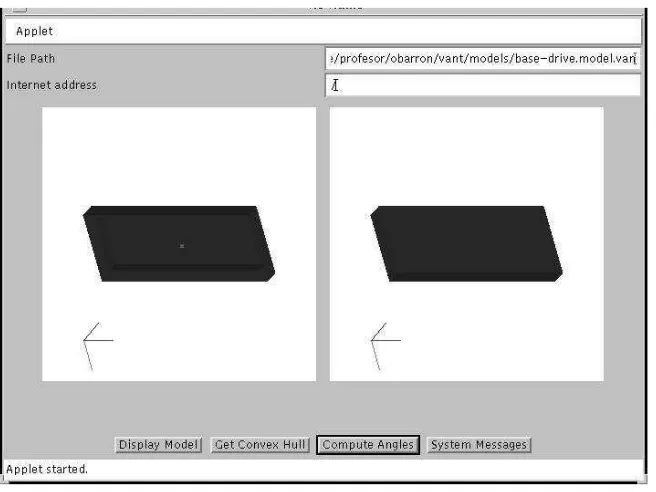

Thegeometridesriptionsarerestoredfromgeometrydatales. Thedatalesan

bewritteninanyformat,aslongasatransformationproedureisprovided totranslate

ittoboundaryrepresentation(BRep). BRepisarepresentation shematausedinsolid

modeling whih desribes the oriented surfae of a solid as adata struture omposed

of verties,edges, and faes [Homann 89℄, asseen ingure 3.4.

Otherwise, the geometri desriptions must be given in terms of CSG ommands

through the use of the Vantage Modeling System [Balakumar 91℄. CSG stands for

\Construtive Solid Geometry" and is another way to represent solids. Within this

approah,solidsarerepresentedasasetofBooleanexpresionsofprimitivesolidobjets,

of a simplerstruture [Homann 89℄, as seen in gure3.5.

The Central Constraint Manager asks the speialized analyzers to ompute other

geometri desriptions (for example, BRep information) and attributes (volume and

enter of gravity) asthey are required.

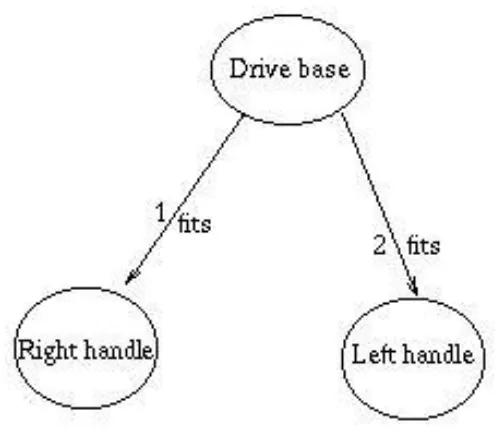

Figure3.6desribesthe sequene ofassembly asanayli direted graphinwhih

the vertexes represent the parts, andthe labeleddireted ars between vertexes dene

the order of assemblyand the relationships between parts.

The work of Anantha, Kramer and Crawford is used to desribe the relationships

between parts, i.e. all the relationships between parts are modeled through the ts,

Figure3.5: CSGrepresentation: Asolidisdesribedbybooleanexpresions ofprimitive

solid objets. The L-shaped solid is represented as a unionof the two boxes.

Figure 3.6: Assembly sequene representation, vertexes are parts, labeled ars dene

[image:40.612.175.352.121.321.2] [image:40.612.192.443.446.666.2]000000

000000

111111

111111

000000

000000

000000

111111

111111

111111

Fits

(a)Fits00000000000

00000000000

00000000000

00000000000

00000000000

00000000000

00000000000

00000000000

00000000000

11111111111

11111111111

11111111111

11111111111

11111111111

11111111111

11111111111

11111111111

11111111111

0000000000

0000000000

0000000000

0000000000

0000000000

0000000000

0000000000

0000000000

0000000000

1111111111

1111111111

1111111111

1111111111

1111111111

1111111111

1111111111

1111111111

1111111111

Parallel

(b)Parallel0000000000

0000000000

1111111111

1111111111

Against

() AgainstFigure3.7: Mating onditions

in appendix A. In the following paragraphs the most important speiations are

presented in reverse order, so readers ould go from a general speiation to a more

detailedone.

An Assembly is dened by a list of sequene steps, a list of parts and a referene

frame. The listof sequene steps must not be empty, and at least 2 parts are needed

toform anassembly.

Assembly

Sequene :iseqSequeneStep

Parts :iseqPARTID

RF :REFERENCEFRAMEID

Sequene 6=hi

#Parts 2

Asequenestepisdened byanId,abasepart, amatingpart,themating

relation-ships between the base part and the mating part, a xtured part, the xture in use,

and the end eetor in use. The xtured part ould be the base part or the mating

partand theremust beatleast onematingrelationshipbetween thebase partand the

mating part.

SequeneStep

Id :SEQUENCESTEPID

BasePart :PARTID

MatingPart :PARTID

MatingRel :iseqMatingData

FixturedPart :PARTID

FixtureInUse :FIXTUREID

EndEetorInUse :ENDEFFECTORID

FixturedPart =BasePart _MatingPart

#MatingRel 1

A Part is dened by an Id, a list of geometry desriptions, a volume, a enter of

gravity and a refereneframe. The listof geometrydesriptions must not be empty.

Part

Id :PARTID

GD :iseqGEOMETRYDESCRIPTIONID

Vol :VOLUMEID

CenterofGravity :CENTERID

RF :REFERENCEFRAMEID

GD 6=hi

A Geometry Desriptionof a 3D-objet is dened by an Id, akind and data.

GeometryDesription

Id :GEOMETRYDESCRIPTIONID

Kind :KindsOfGeometry

Info :Data

Kind =Info:Kind

Datato dene a3D-objet ouldbeBoundary Dataor PropietaryData.

Data =b BoundaryData _PropietaryData

A referene frameisdened by a 44-homogeneous-transformmatrix.

RefereneFrame

Id :REFERENCEFRAMEID

XRotation :R R R

YRotation :R R R

ZRotation :R R R

Position :R R R

Perspetive :R R R

Sale:R

3.2.2 Roboti Cell

The objet representation of the roboti ell is depited in gure 3.8. A roboti ell

desription enapsulates the information of all its omponents: a robot, xtures and

end-eetors (tools and grippers).

As for the assembly, the geometrial desription of the robot, xtures and

end-eetors an be restored from geometri data les and the referene frames will be