www.elsevier.es/rmuanl

ORIGINAL

ARTICLE

Evaluation

of

inter-batch

variability

in

the

establishing

and

quality

control

of

glucose

J.

Moya-Salazar

a,∗,

L.

Pio-Dávila

baM.T.,FacultaddeCienciasyFilosofía,UniversidadPeruanaCayetanoHeredia,Lima,Peru bM.L.T.,HospitalNacionalDosdeMayo,Lima,Peru

Received18October2015;accepted1March2016 Availableonline11June2016

KEYWORDS

Glucose;

Qualityrequirements;

Inter-batch variability; Operativepoint

Abstract Thisresearchevaluatedtheinter-batchvariabilityintheidentificationandquality controlofglucose,accordingtointernationalspecificationsdetailedintheguideCLSIEP-15. Type ofqualitative research, analytical, notexperimental, prospective cross-sectional con-ductedattheDepartmentofClinicalLaboratoryatPolyclinic‘‘LaFe’’duringJanuary2015was performed.Theinter-batchvariabilityforglucoseinthesemi-automatedbiochemicalanalyzer URIT-810withliquidenzymeglucose-LSreagent(GOD-PAP)Valtek® batch140825was evalu-ated.Thecalibrators(CS)werethelotCS-A:140428,CS-B:120912andCS-C:131202.Data analysiswasperformedinSPSSversion20.0statisticalanalyzerandMicrosoftOfficeExcel2010 forWindows.Thevaluesfoundbycalculatingthesigmametricwere:2(SE−0.35),0(SE 1.65) −0.9(SE−0.75) toCS-A,CS-BandCS-C,respectively (p<0.05).OnlyCS-Amightbe abletoimprovetheirperformance,althoughwithgreatercost.Sub-optimalperformance char-acteristicsbyusingstandardcalibratorsshowhighinter-lotvariability,suggestingthechoice andsearchforanewandbettercalibrationmethodtoensureresultsthatcontainnomedically importanterrorsaffectingpatienthealth.

©2016UniversidadAut´onomadeNuevoLe´on.PublishedbyMassonDoymaM´exicoS.A.Thisis anopenaccessarticleundertheCCBY-NC-NDlicense(http://creativecommons.org/licenses/ by-nc-nd/4.0/).

Introduction

Glucose is the main energetic biomolecule for most

liv-ingsystems,responsible formaintainingcellularfunctions

∗Correspondingauthorat:Pacifico957Urb,SanFelipeLima07,

Peru.Tel.:+5114873681;mobile:+511986014954.

E-mail addresses: jeel.moya.s@upch.pe, jeelms@outlook.com (J.Moya-Salazar).

through glucid catabolism. Since its isolation in 1747 by

AndreasSigismund, and the discovery of its configuration

in 1902 by Emil Fisher, the function of glucose has been

explainedandcorrelatedwiththedevelopmentofdiverse

disorders and homeostatic mechanisms for its control.1

Thus,glucoseallowsforthediagnosisofseveraldisorders,

suchasdiabetes mellitus, Cushing’s syndrome,meningeal

inflammatoryprocesses,metabolicsyndrome,

heredofamil-ial intracorpuscular hemolysis, and even enzymopathies,

intoleranceor improper carbohydrate enteric absorption,

http://dx.doi.org/10.1016/j.rmu.2016.03.004

kidney diseases, and in vitro tests for cellular functional statusevaluation,inadditiontobeingusedasa

preserva-tionagent for haemocomponents, among others.2 Hence,

glucoseistranscendentalfordiagnosisinalmostallclinical laboratoriesareas.

Itis mainlyusedfordiagnosing diabetesmellitus (DM),

a metabolic disease which imposes a high economic and

social cost in the world today, especially type II DM.

Diagnosis is made through signs and symptoms and

stim-uli/response tests, such as the oral glucose tolerance

test (OGTT), among others.3,4 Moreover, explorations of

carbohydrate metabolism are employed, such as random

glycemias,fastingplasmatic glycemias,the glucose toler-ancewithcorticoids test and,recently, withtheglycated hemoglobinA1Ctest,aswellasplasmaticinsulinlevel eval-uations,peptideCandglucagondosing,andglucoseinurine andlipidprofiles.5---7

Determined valuesindicate how the organism controls

glucose.Biochemicaldeterminationisgenerallyperformed

with reducing methods, enzymatic methods (hexokinase,

glucose-oxidase,andglucose-dehydrogenase),and

commer-cialdeterminationsbydrychemistryforclinicaldiagnosis,

aswell asfor in-homemonitoring andimmunoradiometric

trials.Enzymaticmethodsincommercialpresentationsare

the most utilized, followed by patient monitoring by dry

chemistry, usually with acceptable sensitivity ranges and

errormargins.8Nevertheless,glucoseisoneofthe metabo-liteswhichsuffersmorepre-analyticandanalyticchanges,

and onewhich presents an elevated biological intra-and

inter-individual variability. However, the reagent maker

incorporates internationally-validated technical specifica-tions;duetodifferentfactors,thesecannotbereproduced intheroutinelaboratory,thusmakingqualitycontrolunder workconditionswhichguaranteethequalityoftheirresults necessary.9,10

Parameterstoensurequalityinclinicalbiochemistry,as

described by the Clinical Laboratory Standards Institute

(CLSI), include analyticalmethods and verification guides

which lead to a correct planning and choosing of

qual-itycontrolrulesforcontinuousmonitoringofperformance

underworkconditions. Obtainingof thesedatesthetotal

erroroflaboratorymethod(Tea)iscomparabletothe

max-imum permissible error designed from different sources

liketheClinicalLaboratoryImprovementAmendments1988

(CLIA’88), biological variability, RCPA regulatory

require-ments,etc. Subsequently,planning andmethodcontrolas

wellasqualitywillshowcontinuousimprovement.11 Quality verificationof amethod’s analytical character-isticsis applicable toallkindsof laboratories.In addition

tomeasurable dataonthe system’sperformance

(inaccu-racy and bias), quality requirements and real reference

valuesarenecessary.12Qualityrequirementsforglucoseare diverse,withmaximumquantifiablepermissibleerrorvalues upto±10%(±6mg/dl)inmostsources.5,13

Subsequent to the establishment of internal quality

control,thesamereagentlotshouldbemaintainedin bio-chemistry(andhematology)for ayear,inordertocontrol performance.14Likewise,variabilityofthecontrolmaterials fromlot-to-lotshouldbeminimal.Sinceitrepresentsasmall amountofobservedvariation,thisshouldnotexceed10%.15 Amongstthecommunity,thecirculationoflyophilized con-trolsispredominant,which,unlikeliquidcontrols,present

highererrorandstabilityandlowercost,butrequirecareful handlingofvolumetricmaterial,distilledwaterand recon-stitution.

Withinthecommunity,therearefewclinicalanalysis lab-oratories withquality systemsin biochemistry. Consistent

with the evolution of laboratories, most National

hospi-tals and some private Health Centers in Lima maintain

internal,externalandinter-laboratoryquality implementa-tionwithoutacosmopolitanreachinthecapital.Thevast

majority of new clinical laboratories with economic

limi-tations, interest of profit, or those which are unfamiliar withtheclinicalimpactofresultswithoutaqualitysystem onlyuse‘‘standardcalibrator’’controls,usually

semiauto-maticbiochemicalanalyzersprovidedbythemanufacturer

asaqualityreferenceforworkperformanceevaluationand resultreliability.

Itisevidentthatthelackofconscienceaboutthissubject andtheampleuncertaintyproducedintheresult,sincethe errorisnotquantifiedorcorrected, willbemagnified pro-gressivelyandbecomeuncontrollable.Inthisregard,some

of themost commonlyusedreagents inclinical chemistry

amongstthecommunitydonothavethesamelotinsidethe

kit(inotherwords,adifferentlotfortheenzymaticreagent andforthestandardcalibrator).Then,howcanthequality oftheresultsbeensuredintheseconditions?

The objectiveof thisinvestigation wastoassess inter-batch variabilityin the determination andquality control

of glucose, according to the international specifications

detailedintheCLSIEP-15-A3guide.

Method

and

materials

A qualitative, analytic, non-experimental, prospective

cross-sectional study wasconducted in the Clinical

Labo-ratoryDepartmentatthebiochemicalareaofthe‘‘LaFe’’ PolyclinicHealthCareCenterduringJanuary,2015.Glucose inter-batch variabilitywas assessed according tothe CLSI EP15-A3guide,highlightingtheusefulnessof‘‘control

let-ters’’ (metric sigma, power control chartand Normalized

OPSpecschart).12

Sample

On-probabilistic,samplingintentionallybyconvenience.

Biochemicalanalyzer

In order to perform determinations, we used aURIT-810

MedicalElectronic(Guangxi,PRChina)semiautomatic

bio-chemicalanalyzer,whichwasstabilizedto220V,100VA.

Reagents

Valtek®Glucose-LSenzymaticliquidreagent(Valtek diagno-sis,SantiagodeChile,Chile)lot140825,withastoragerange

between 2 and 8◦C, 50ml bottle, with glucose

oxidase-peroxidase (GOD-PAP) enzymatic colorimetric method,

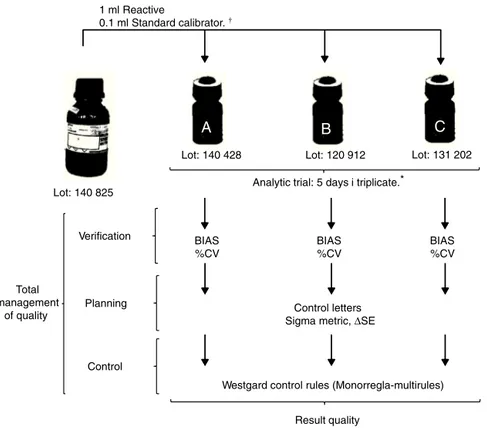

A

B

C

1 ml Reactive

0.1 ml Standard calibrator.

Lot: 140 825

Lot: 140 428 Lot: 120 912 Lot: 131 202

Analytic trial: 5 days i triplicate.*

BIAS %CV

BIAS %CV

BIAS %CV

Control letters Sigma metric, ∆SE

Westgard control rules (Monorregla-multirules)

Result quality Verification

Planning

Control

* Total management

of quality

Established underthe work protocol forGlucosedetermination–LS Valtek® Analytictrials describedbytheCLSI EP-15 guide.

Figure1 Workschemewithintheglucoseserummatrix.

andCcalibrators(CS-BandCS-C)oflot120912and131202, respectively(100±1mg/dl).

Controlreagent

Inordertoperformmethodverification,thekit’s‘‘standard calibrators’’wereutilizedascontrolsaccordingtooperative needs.

Datarecollectiontechniqueandsampleprocessing

Accordingtothemaker’srecommendations,CSswere

sta-bilizedat roomtemperature(roomtemperature25±2◦C)

for10minbeforeprocessing.Theequipmentstabilizedfor

10min beforetheanalyticruns.Ablankreagentwasused

beforetheanalysisverificationfromlot-to-lot. Inorderto

evaluateprecision,threesetsofmeasurementsweremade

fivedaysinarow.Fortheevaluationofveracity,duplicates ofthe5daysoftheprecisionprotocolofthe3control mate-rials for glucose were necessary (CS-A, CS-B and CS-C).12 Analyticrunswereconductedbytheinstitution’spersonnel underthe work’s protocol specifications.17 Procedures for

glucoseverification wereconducted usingtheCLSI

EP-15-A3guide,measuredinstandarddeviation(SD)andvariance

coefficient (%VC) toasses bias and imprecision. With the

dataobtainedfrom%VC,biasandTea, thedotand

opera-tivelinesweredeterminedtoevaluatetheperformanceof

themethodology, demonstratedingraphics withincontrol

letters.Thesedeterminetheamountofcontrolsnecessary

fortheanalyticalrun,aswellastheclinical assaycontrol rules.18TheworkoutlineisshowninFig.1.

Dataanalysistechnique

Dataanalysis wasdone using the statistical analyzer IBM

SPSS, version 21 (Armonk, USA) and MS Excel 2010

(Red-mond,USA)forwindows.Thequalitymatrixwasdeveloped

inanExcelsheetshowingSD,%VC,Tea,sixsigmaandcritical systemicerror(SDEorSE).

Limitations

Severallimitations oughttobeaddressed before interpre-tingresults.

First,theremaybefailures inthe conservationor sta-bilityofstandard calibrators, withindomesticdistribution byfranchisesorthebrand’scommercialdistributors.These maybethecauseforerroneousresults.Asecondlimitation

is the fact that we were not able to compare the

inter-batch glucose variability results found in this study with

thosedescribed by Valtek reagentsfor glucose,which do

notshow significant systemic differences in accuracy and

imprecisionwhencomparedtoothercommercialreagents,

obtainedusingtheBSseriesMINDRAYauto-analyzer.16Athird limitationisthattheclinicalbiochemistrylaboratorywhere

thestudy wasconducted is not accredited under the ISO

15189 norm,but it does have the technical and

manage-rialrequirementsoftheISO 9001normimplemented.The

Table1 Averagebias%,%CV,teaforglucosewiththreeCS.

CS-A CS-B CS-C

bias% 0 10 21

%CV 6 11 12

Teaa 10 10 10

Sigma 2 0 0.9

SE 0.35 −1.65 −0.75

aQualityrequirementsunderCLIA’88.

and VALTROL-P (code210-110) areused in the

biochemi-calfieldonaweeklybasis.Lastly,notalllinkedprotocols wereanalyzedwithmethodverification(linearity,detection limit,referencevalues,etc.)11,17.Despitetheselimitations, thisresearchisthefirsttodescribeverificationprocesses, planningandqualitycontrolusingstandardcalibratorssuch ascontrolserainclinicalbiochemistry.

Results

Oftheconductedresearch,thevaluesfoundbythesigma

metriccalculationwere2,0and−0.9,forCS-A,CS-Band CS-C,respectively.Theseindicateaverypoorperformance, whichcannotbecontrolledormaintainedwithinthe appli-cationofastatisticalcontrol(p<0.05).19(Table1)

Sigma metric is a process improvement methodology.

Itsonly goal is toreach less than one defect per million

(99.9997% successes). Although quality requirements are

different for each magnitude, these unify with six sigma

inordertocomparemethodswithasinglevalue.20 Inthis

sense,we areable toexpressvalues andknow statistical

controlstrategiesbasedonsigma,asshowninFig.2asan example.

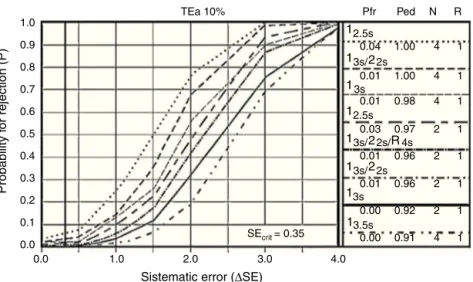

Othercontrollettersareoperativespecificationgraphics

(OPSpecs) and power control chart. Power control chart

represent the most powerful graphic because of the vast

amount of data which can be obtainedfrom them during

quality planning. These requires SE calculations, based

onthemethod’smaximumpermissibleerror,whichshould

not be more than the quality requirements (up to 90%

of quality assurance), which equals the statistical value

of 1.65 standard deviations.21 These functions present

the information about the performance of a rejection

probability graphic control rule versus the analytic error measures,asshowninFig.3.

Every one of the cases underwent 2 control levelsfor

every analytical run (n=2). Choosing one control rulefor every analyte,therearefeweralarms ininternal control, thusfreeingtheanalyticalrunwithagoodchanceoferror detectionandalowprobabilityofrejectinggoodruns.Every letterbeginswiththechoiceofcontrolrules,accordingto

each case (mono-rules or multi-rules) whichevaluate and

controlimmeasurablesystemicandrandommistakes.

Discussion

Performancecharacteristicswerenotoptimalwiththeuse

of standardcalibratorsfor glucosedetermination, accord-ingtothesigmametricevaluation(Table1).Thesedeficient performances(sigma<3)suggestachoiceandsearchfora

newandimprovedcalibrationmethodwhichimproves

pre-cision,sincethereisnominimumqualitycontrolunderthe studied conditions. The analysisof results with statistical controlstrategychartsbasedonsigmametricsprovesthat

Manual selection TEa=10.00 %(SE)

Probability f

or rejection (P)

Process metric (Sigma-scale)

1.65 2.65 3.65 4.65 5.65 P

ed P

fr

1

1 2 3s 0.03

0.04 1

2.5s

3s 2s 4s 1.00

1.00 4 1

4 1

0.03 1.00 4 1

0.01 1.00 4 1

0.01 0.99 4 1

0.03

0.01 0.96

0.94 2

2 1

1

0.01

4.0 3.0

2.0 1.0

Control metric (∆SE, multiples of s)

0.0 0.0 0.1 0.2 0.3

Sigma = 2

∆SEcrit = 0.35

0.4 0.5 0.6 0.7 0.8 0.9 1.0

0.94 2 1 2s 4s 1s /

2 /

13s

13s

13s 12.5s

2s 2 /

2s 2 /

13s 2s/2 R /

4s R / R / /4

N R

1.0

TEa 10% Pfr Ped N R

0.9

0.8

0.7

0.6

0.5

Probability f

or rejection (P)

0.4

0.3

0.2

0.1

0.0

0.0 1.0 2.0

Sistematic error (∆SE)

SEcrit = 0.35

3.0

0.00

1

0.91 4 1 0.00 0.92 2 1

13s

1 2

2 R

2s 2s/ 4s

3s/

1 1

3s/

22s

13s/

13s

2.5s

12.5s

0.01 0.96 2 1 0.01 0.96 2 1 0.03 0.97 2 1 0.01 0.98 4 1 0.01 1.00 4 1 0.04 1.00 4 1

4.0 3.5s

Figure3 PowercontrolchartforglucoseCS-A.Showthateventhoughwith10%ofprobabilityforrejectionbeableestablisha correctplanningandchoosingofqualitycontrolruleswithstatisticalcontrolchart.

analytical qualitycontrol management with standard

cal-ibrators providedby the manufacturer are not enough to

ensure results free of medically significant errors affect-ingthehealthofthepatient.Moreover,statisticsshowthe specificconcentrationtestperformanceinworkconditions inherenttothementionedlaboratory.22

The vast majority of clinical chemistry laboratories in

Lima,which usemanualor semiautomaticmethodologies,

presentahighdegreeofinaccuracyinglucoseand choles-teroldeterminations,highlightingnotonlythepoorquality oflabresults,butalsotheneed fordynamicandefficient controls which ensurequality inprocesses.23 Bynot using Good ClinicalLaboratory Practices, theerror is not quan-tified,thusuncertaintyintheresultcreatesabadclinical diagnosis. Itis worth notingthatqualityis nota common characteristicamongstbiochemicallaboratoriesinLima.A

contrariosensu,withthedevelopmentandnormalizationof

clinicalmedicine,doctorsandpatients areexpectinghigh qualityresults,whichis achallengefor alllaboratoriesin

thecommunity.

Results provided during the calibrator’s analytical run

shouldbetruthfulandpreciseinordertocertifythatroutine

analyticaldeterminationsensureaminimumqualityanda

correctclinical interpretation, in additiontobeinguseful fortheirinter-laboratorycomparability.22,23

OPSpecs’ statistical control letters as well, as power

control chart, describe the acceptable imprecision and

inaccuracy for a method and qualitycontrol necessary to

supervise performance, as well as the test performance

understableconditions,andwarnifthereareanychanges thatmayaffectthereport.Thegoalistoobtain<90%

prob-ability of error detection (Ped or AQA) and less than 5%

probabilityof false rejection (Pfr),with an N(amount of controlsbeinganalyzed)aslowaspossibleandinasingle analytical run.24 In the example shown in Fig. 3,none of therules is eligible, withtwocontrols peranalytical run.

Through the use of control materials ‘‘CS’’ anda proper

statisticalmanagement,weareabletoprovethatnorule

orcontrolisusefulintheverificationofthemethod.25,26,27

In the same manner, the error in Valtek’s critical

glucose-LSlevelswereestimated.Thesystemicerroristhe

differencebetween the conventionallytruthful value and

the median value of a number of determinations which

are experimentally measured. Within this investigation,

we were able to find a 0%, 10% and 20% of bias for

CS-A, CS-B and CS-C, respectively. On the other hand, the

systemic error, that is to say the resultant precision of

the approximation’s repeated measured values, were 6%,

11% and 12% of CS-A, CS-B and CS-C, respectively. These

continuous quantitativevariables, when expressed

graph-ically, show thewide inter-batchvariability and error for

glucose.Of these, only lot140428 (CS-A) could be

capa-ble of improving its performance of being indispensable

for analysis in the laboratory, in other words,

capa-bleof recognizing, monitoring, minimizing and correcting

errors, although it would be costly to maintain it within

quality.14,15,17

Thecausesofthisvariabilitycouldbelinkedtodifferent motives,whichitisnotanobjectiveofthisinvestigationto describe.Butitistoconsiderwhetherornotsomefactors aredirectlyinterfering,suchthematrixtype,signal varia-tionbetweenequipment,lackofnoisecontrol,CSbehavior inworkconditions,measuredcommutability,transportation

and control storage and lack of preventive maintenance,

toname afew.In consequence, fullroutinemonitoring is

ineludible.

Glucose concentration is very important for

endocri-nologists,diabetologistsand diabeticpatients,evenwhen

dysglycemicor apparently healthy, particularly when the

concentrationisclosetothe upperlimitof thereference interval(±10%or6.1mmol/L).28Theconcerningprevalence ofdiabetesandprediabetessuggeststheimmediate prioriti-zationofhealthcareinordertoavoidfuturecomplications.

Diagnosis by stimuli-response and/or explorations of the

carbohydrate metabolism ought to be evaluated for all

phenomenawhichmayinterveneduringeveryanalysisand

generate non-quantifiable errors, which will not ensure

Conclusions

In this investigation, the measure of standard glucose

calibrators was performed in order to prove inter-batch

variability and the application of control letters,

follow-ingevaluationproceduresrecommendedby theCLSIEP15

guide.Totalerrorwasidentifiedandqualitycontrol

neces-sarytocontrolthemethodperformancewasevaluated.

Thewideinter-batchvarietyworksagainstresult

repro-ducibility and quality, hence we must opt for a different

controlmaterialforqualitymonitoringinglucose-LS

deter-mination with Valtek® reagents. Quality planning helps

clinicalanalysislaboratorieswhichdon’tquantifyerrorsor guaranteeatrustworthy diagnosisfacequalitychallenges.

However,theproblem withvariabilityand qualitycontrol

estimationsisthatmostlaboratoryusersarenotfamiliarized withtheconcepts and themeasuringprocess isstill

hier-archically restrained toreference methods, which ensure

processtraceability,butarenotaccessibleforeveryclinical

laboratorynationwide.

Itis notaproblemfor ourmethodtoworkwitha

cer-taindegree of error. The problem is for this error tobe

greaterthanthe maximumpermissibleamount, according

tothemethod’squalityspecifications.Inthissense,quality ofresultsisnotguaranteedbyusingonlystandard

calibra-torsprovidedby themanufacturer; thisevaluationshould

bethestartingpointtodevelopqualityprocesses.

Analytical chemistry shouldnot only equilibrate a

col-lection of data and methods, but obtain representative

samples,optimizemethodsand interferencemanagement

andguaranteequalityof data.We hope thisinvestigation

isabletopromotetheuseofoptimalcontrolmaterialsfor correctplanningandqualitycontrolinclinicalanalysis lab-oratories.

Funding

sources

Self-financedbytheauthors.

Conflict

of

interest

Theauthorsdeclarenottohaveanyconflictsofinterest.

References

1.FisherE.Synthesesinthepurineandsugargroup.NobelLect. 1902:21---35.

2.PrietoVJ,YusteAJ.Laclínicayellaboratorio-Balcells,vol.3, 20ed.Espa˜na:Elsevier-MassonPublisher;2006.p.47---50. 3.MoyaSJ,PioDL.Evaluationcriteriafortheinterpretationoftest

oforalglucosetolerance(OGTT)inHospitalNacionalDocente Madre-Ni˜no‘‘SanBartolome’’.MedUniv.2015;17:147---52. 4.Puig-DomingoM,LeivaHA.Diabetesmellitus:concepto,

clasi-ficaciónyetiología.In:CasanuevaFreijoF,VázquezGarcíaJA, editors.Endocrinologíaclínica.Espa˜na:DíazDeSantos;1995. p.241---9.

5.American Diabetes Association.Diagnosis and classification of diabetes mellitus. position statement. Diabetes Care. 2010;33:562---9.

6.TietzNW.Fundamentalsofclinicalchemistry.Philadelphia:WB Saunders;1996.

7.DeBuitragoJM.Bioquímicaclínica.Amsterdam:Elsevier Pub-lisher;1998.

8.SuardíazJ,CruzC,ColinaA.Laboratorioclínico.La Habana: EditorialCienciasMédicas;2004.p.12---3.

9.KrouwerJ.Settingsperformancegoalsandevaluatingtotal ana-lyticalerrorfordiagnosticassays.ClinChem.2002;6:919---27. 10.ChenH, Zhang L, Bi X, Deng X.Two evaluation budgetsfor

themeasurementuncertaintyofglucoseinclinicalchemistry. KoreanJLabMed.2011;31:167---71.

11.BadrikT.Qualityleadershipandqualitycontrol.ClinBiochem Rev.2003;24:81---93.

12.CLSIEP-15-A3.Userverificationofprecisionandestimationof bias;approvedguideline----ThirdEdition.950WestValleyRoad, Suite2500,Wayne,Pennsylvania19087,USA:Clinicaland Lab-oratoryStandardInstitute;2014.

13.WestgardJ,SeehaferJ,BarryP.Allowableimprecisionfor lab-oratory test based on clinical and analytical test outcomes criteria.ClinChem.1994;10:1909---14.

14.ÁlvarezFV,MontserratMM,KirchnerJA,etal.Elalgoritmode Westgardcomosistemadecontrolinterno.Sociedadespa˜nola deQuímicaClínica.QuímClín.1990;9:97---101.

15.ISO 15189 Medical Laboratories. Particular requirements for qualityandcompetence,2003.Geneva,Switzerland: Interna-tionalOrganizationforStandards;2007.p.2.

16.Trinder P. Determination of bloodglucose using an oxidase-peroxidasesystemwithanon-carcinogenicchromogenic.JClin Pathol.1969;22:158---61.

17.Valtekdiagnosis.Glucosa---LS(GOD---PAP)reactivolíquidopara ladeterminaciónfotométricadeGlucosaensuerooplasmay otrosfluidosbiológicos.Valtek, ˜Nu˜noa,SantiagodeChile;2010. 18.Guglielmore R, De Elías R, Kiener O, Collino C, Barzón S. Methodverificationinacertifiedlaboratoryandinternal qual-itycontrolpacification.ActaBioquímClínLatinoam.2011;45: 335---47.

19.D’IsaG,RubinsteinM.Sixsigmaenellaboratoriodequímica clínica.Bioanalisis.2009;1:12---5.

20.Terrés-SpezialesA.Sixsigma:determinacióndemetas analíti-cas con base en la variabilidad biológica y la evolución tecnológica.RevMexPatolClín.2007;54:28---39.

21.Westgard J, Groth T. Powerfunctions for statistical control rules.ClinChem.1979;6:863---9.

22.KonieczkaP,NamiesnikJ.Quality assuranceand quality con-trolintheanalyticalchemicallaboratory.NewYork:CRCPress Taylor&FrancisGroup,LLC;2009.p.97---129.

23.SandovalVM,SalazarCY,LoliPR,HuamánGO.Inexactitudenlas determinacionesbioquímicasdeglucosa,colesteroly triglicéri-dos,enlaboratoriosclínicosdeLima.RevInvUnivNorbWiener. 2014;3:31---40.

24.WestgardJ.Basicmethodvalidation.3ed.Madison,WI: West-gardQC,Inc;2008.

25.WestgardJO,SteinB.Anautomaticprocessforselecting sta-tisticalQCprocedures toassureclinicaloranalytical quality requirements.ClinChem.1997;43:400---3.

26.WestgardJO, GrothT. Powerfunctions for statisticalcontrol rules.ClinChem.1979;25:863---9.

27.Darán M. Control de calidad en los laboratorios clínicos. Barcelona:EditorialRevertéS.A.;2002.

28.WestgardJ,EhrmeyerS,FallonKD.CLIAfinalrulesforquality systems.ClinChem.2004;1:107---17.