Instituto Tecnológico y de Estudios Superiores de Monterrey

Campus Monterrey

Lic. Arturo Azuara Flores:

Director de Asesoría Legal del Sistema

Por medio de la presente hago constar que soy autor y titular de la obra titulada:"

_", en los sucesivo LA OBRA, en virtud de lo cual autorizo a el Instituto Tecnológico y de Estudios Superiores de Monterrey (EL INSTITUTO) para que efectúe la divulgación, publicación, comunicación pública, distribución y reproducción, así como la digitalización de la misma, con fines académicos o propios al objeto de EL INSTITUTO.

El Instituto se compromete a respetar en todo momento mi autoría y a otorgarme el crédito correspondiente en todas las actividades mencionadas anteriormente de la obra.

De la misma manera, desligo de toda la responsabilidad a EL INSTITUTO por cualquier violación a los derechos de autor y propiedad intelecutal que cometa el suscrito frente a terceros.

Nombre y Firma AUTOR (A)

Methodology For Desing and Integration of Collaborative E

Engineering EnvironmentsEdición única

Title Methodology For Desing and Integration of Collaborative E Engineering EnvironmentsEdición única

Authors Ricardo Mejía Gutiérrez

Affiliation Itesm

Issue Date 20031201

Abstract Tesis presentada para obtener el grado de Maestro en ciencias especialidad en Sistemas de Manufactura

Item type Tesis

Rights Open Access

Downloaded 18Jan2017 17:56:20

SUPERIORES DE MONTERREY

CAMPUS MONTERREY

DIVISIÓN DE INGENIERÍA Y ARQUITECTURA

PROGRAMA DE GRADUADOS EN INGENIERÍA

TECNOLÓGICO

DE MONTERREY

METHODOLOGY FOR DESIGN AND INTEGRATION OF

COLLABORATIVE EENGINEERING ENVIRONMENTS

TESIS

PRESENTADA COMO REQUISITO PARCIAL

PARA OBTENER EL GRADO ACADÉMICO DE

MAESTRO EN CIENCIAS

CON ESPECIALIDAD EN SISTEMAS DE MANUFACTURA

RICARDO MEJIA GUTIÉRREZ

INSTITUTO TECNOLÓGICO Y DE ESTUDIOS

SUPERIORES DE MONTERREY

CAMPUS MONTERREY

DIVISIÓN DE INGENIERÍA Y ARQUITECTURA

PROGRAMA DE GRADUADOS EN INGENIERÍA

Los miembros del Comité de Tesis recomendamos que la presente Tesis del Ing. Ricardo Mejía Gutiérrez sea aceptada como requisito parcial para obtener el grado académico de Maestro en Ciencias con especialidad en:

SISTEMAS DE MANUFACTURA

COMITÉ DE TESIS

Dr. Arturo Molina Gutiérrez Asesor

Ing. Adán López Miranda Dr. Ciro Rodríguez González Sinodal Sinodal

APROBADO

Dr. Federico Viramontes Brown

A mi familia.

En especial a mis padres Richer y Silvia, por brindarme su amor y por enseñarme el ejemplo de lucha y lealtad. A Camila, Juanda y Antonia, por quererme tanto y por creer en mí. A la Abuelita Emilia por ser el foco familiar y velar por todos y cada uno de nosotros. ¡Gracias a todos por su apoyo incondicional! Los quiero mucho.

A Colombia.

Agradecimientos

En especial al Dr. Arturo Molina

Por la oportunidad de trabajar todo este tiempo en su grupo y por la confianza que siempre me brindó, así como sus valiosas enseñanzas durante todo este proceso de aprendizaje y desarrollo de experiencias. Gracias por el apoyo para mis estudios de maestría, estancias en el extranjero y su asesoría en el desarrollo de este proyecto de tesis. Como profesional y persona, creo que es un gran ser humano y le deseo muchos éxitos más.

Al Dr. Ciro Rodríguez y al Ing. Adán López

Por aceptar participar en mi comité de tesis y contribuir con sus valiosos comentarios para la culminación de la misma

Cátedra de Investigación en Mecatrónica

El desarrollo del presente trabajo de tesis ha sido apoyado con los fondos de la cátedra de investigación en Mecatrónica del ITESM, Campus Monterrey.

A Laurita

Por tu incondicional apoyo y paciencia en todo este tiempo. Gracias por tu ayuda, en especial a los duros momentos en la terminación de esta tesis y por todos los buenos momentos que hemos compartido. Gracias por confiar en mí!

Al gpomol

En especial a: José Luis, Joaquín, Marcela y Nathalie, por su larga y especial amistad y con quienes compartí muchos momentos.

A la actual generación: Manfred, Paco, Compi, Maddito, Andrés, Ana María, Luis, David, Paola, Roberto, Emilio, Alma y Gerry; y a Mike, ya como profesor.

A IECOS, el Ing. Mario y Mario E.

A las generaciones pasadas: Veruz, Moni, Maria Paula, Edo, Rubén, Fernando, Camilo, Carlos, Pedro, Daniel, Martín, Vero, Kike, Julián, Eunice, Tere V., Myrna, Raúl y chano. (Espero no se me pase nadie....)

A los que han venido de fuera: Marc, Kai, Amir y Guta. Mejor dicho, a todos aquellos que participaron en el grupo de trabajo, y a las múltiples generaciones con las que tuve el gusto de compartir buenos y malos momentos. Gracias por su amistad y apoyo durante todo este tiempo de trabajo y estudio. A todos ustedes, les deseo lo mejor!

A México

SUMMARY

The globalization of the industrial activities and decentralization of the product life cycle activities, nave lead companies to work collaboratively and simultaneously with distant engineering partners. The expansión of Internetbased tools has opened new opportunities for collaborative work improvement, through the development of a new generation of tools designed to support this kind of activities. For these reasons the creation of Collaborative eEngineering Environments (CeEE) has been a key issue in nowadays Information Technology's challenges, in order to enable people to collaborate and interact on the development of a new product regardless of their geographic locations. The presented research describes a methodology for the design and integration of CeEE. The definition of this methodology was accomplished under an action research approach, as the research methodology used, where the experiences in developing Collaboration environments has lead the author to define an structured way of creating CeEE in order to transfer these concepts to the industry. The methodology has four main steps: I) Define the company requirements and model ASIS development process, II) Assess ASIS model, and model TOBE development process, III) Design and integration of environment and applications, which includes: III.1) Modeling the workflow (MODEL), III.2) Selection and Integration of eEngineering applications (INTÉGRATE), III.3) Connection of environment and application using standard and web protocols (CONNECT) and III.4) Definition of performance measures and monitoring techniques (MONITOR). The last stage IV) Execute and manage the CeEE. The methodology was used for the development of three CeEE, and the action research cycles allow the improvements detection from one to the next one. The principal results obtained were: 1) A taxonomy for supporting applications in Integrated Product Development was proposed, based on the experiences of applying and improving the methodology and it is used as a tool for the computer applications integration, 2) A revised and improved methodology for the CeEE design, integration and transfer to the industry was developed; and 3) the improvement of the methodology was achieved applying it in three CeEE scenarios. The major conclusions from this research are: a) The applications taxonomy allows the identification of the necessary tools that engineers needs as a minimal support in their activities execution, b) Not all the activities require collaboration supporting tools, but all of them requires the exchange of Information and knowledge, c) the functional tools, are specific supporting tools, used on specific activities, while the coordination, collaboration and Information management are platforms standardized to the whole engineering life cycle, d) the technology may not be an obstacle in the collaboration efforts of the enterprises, and e) related to the application of Action Research, it can be concluded that cycling process of execution and reflection, allow identification of improvements both, for Technologies as well as for the automated process in execution (workflow). As a result, the enterprises must consider that in the near future collaborative activities for engineering will be the key for the competitive position in a globalized market.

Ricardo Mejía Gutiérrez

CONTENTS

SUMMARY I

CONTENTS II

LIST OF FIGURES VI

LIST OF TABLES VIII

CHAPTER1. INTRODUCTION 1

1.1 Background 1 1.2 Research justification 1 1.3 Objective and relevance of the research 3 1.4 Scope of the research 3 1.5 Thesis organization 4

CHAPTER 2. LITERATURE REVIEW 6

2.1 Introduction 6 2.2 Market analysis 8 2.2.1 From traditional engineering, to Collaborative Engineering 8 2.2.2 Industry background 9 2.3 Collaborative Engineering Environments 10 2.3.1 Context 11 2.3.2 Related research 13

CHAPTER 3. RESEARCH METHODOLOGY 17

3.1 Introduction 17 3.2 What is action research? 19 3.3 Action research cycles 20

CHAPTER 4. METHODOLOGY FOR DESIGN AND INTEGRATION OF

COLLABORATIVE EENGINEERING ENVIRONMENTS 23

4.1 Step I: Define the company requirements and model the ASIS of the development process 26 4.2 Step II: Assess the AS IS, and model the TOBE 27 4.2.1 Process Domain 28 4.2.2 Information /Knowledge Domain 29 4.2.3 Organization Domain 30 4.2.4 Technology Domain 31 4.3 Step III: Design and integration of environment and applications 32 4.3.1 MODEL: Modeling the workflow 32 4.3.1.1 Créate and model the Workflow 33 4.3.1.2 Define the people ¡nvolved ¡n modeling 35 4.3.1.3 Followthe modeling steps 35 4.3.2 INTÉGRATE: Selection and Integration of eEngineering

applications 36 4.3.2.1 Identification of Functional tools 38 4.3.2.2 Definition of Coordination, Collaboration and

I nformation/Knowledge Management tools 40 4.3.3 CONNECT: Connect environment and applications using

standard and web protocols 41 4.3.3.1 Identify required information from partners involved 43 4.3.3.2 Define connectivity solution through exchange formats 45 4.3.4 MONITOR: Definition of performance measures and

monitoring techniques 48 4.3.4.1 Identify the types of measures (default from WFMS and

userdefined) 50 4.3.4.2 Define customized performance measures 51 4.3.4.3 Determine the monitoring level 53 4.4 Step IV: Execute and manage the CeEE 54 4.4.1.1 Configure the generic environment settings 54 4.4.1.2 Reléase the workflow model 55 4.4.1.3 Execute the Workflow Runtime 56 CHAPTER 5. CASESTUDY 58

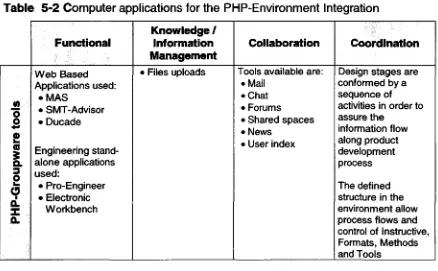

5.1 Cycle 1: Php groupware Technologies 60 5.1.1 Step I. ASIS 60 5.1.2 Step II. TOBE 60 5.1.3 Step III. Environment 61 5.1.3.1 Step 111.1 MODEL 62 5.1.3.2 Step III.2 INTÉGRATE 63

Ricardo Mejía Gutiérrez

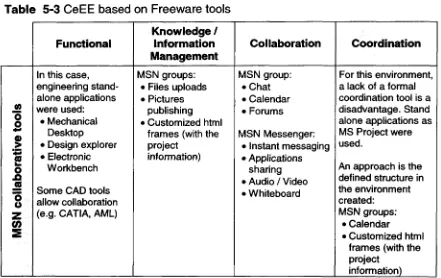

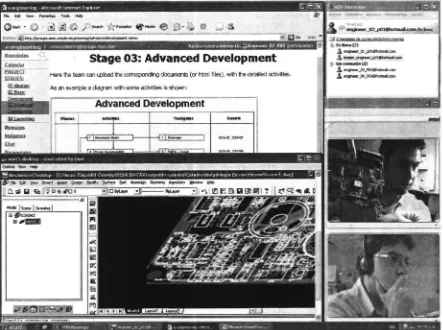

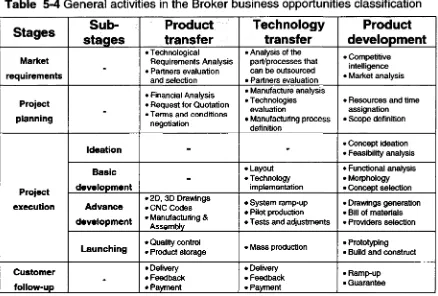

5.1.3.3 Step III.3 CONNECT 64 5.1.3.4 Step III.4 MONITOR 64 5.1.4 Step IV. Execute 64 5.2 Cycle 2: Freeware applications 65 5.2.1 Step I. ASIS 66 5.2.2 Step II. TOBE 66 5.2.3 Step III. Environment 66 5.2.3.1 Step III.1 MODEL 66 5.2.3.2 Step III.2 INTÉGRATE 67 5.2.3.3 Step III.3 CONNECT 68 5.2.3.4 Step III.4 MONITOR 68 5.2.4 Step IV. Execute 69 5.3 Cycle 3: Industrial Scenario Case Study 70 5.3.1 General description of the scenario 70 5.3.1.1 Industry networks management 70 5.3.1.2 Customer Background 71 5.3.1.3 Product description 73 5.3.2 Design the Collaborative eEngineering Environment for

Aerospace Maintenance Tooling 73 5.3.2.1 Step I. ASIS 73 5.3.2.2 Step II. TOBE 77 5.3.2.3 Step III. Environment 77

5.3.2.3.1 Step III. 1 MODEL 81

5.3.2.3.2 Step 111.2 INTÉGRATE 82 5.3.2.3.3 Step III.3CONNECT 84 5.3.2.3.4 Step 111.4 MONITOR 85

5.3.2.4 Step IV. Execute 86 CHAPTER 6. RESULTS AND CONCLUSIONS 89

6.1 Results 89 6.2 Conclusions: 89 6.3 Further research: 91

REFERENCES 92

APPENDIXES 97

APPENDIX A. Collaborative environments related research (description)

APPENDIX B. Computer Applications Taxonomy B.1 Functional Tools

B.1.1 Functional Tools based on Information B.1.2 Functional Tools based on Models B.2 Coordination Tools

B.3 Collaboration Tools

B.4 Tools for information / knowledge Management

APPENDIX C. The IGES, DXF and STEP exchange formats C.1 IGES (Initial Graphics Exchange Specification)

C.2 DXF (Data eXchange Format)

C.3 STEP (STandard for the Exchange of Product model data)

APPENDIX D. Process domain for cycle 3: product transfer case study

APPENDIX E. IBM WebSphere™

E.1 Technology Architecture and Application Architecture. E.2 Highlevel overview of the WebSphere platform

E.2.1 WebSphere Foundation & Tools E.2.2 WebSphere business portáis

E.2.3 WebSphere Business Integration products

E.3 Applications to Implement CeEE Architecture from Cycle 3: Landing Gear case study

Ricardo Mejía Gutiérrez

LIST OF FIGURES

Figure 11 Integrated eServices offered by eHUBs [Molina, 2003] 3 Figure 21 Tendencies to 21st Century engineering and manufacturing [Wright,

2001] 7 Figure 22 Global product development [Molina, 2003] 9 Figure 23 A Virtual Collaborative Design Environment conceptual model

[Bochenek and Ragusa, 2001] 12 Figure 24 Opportunity in early design stage [Wang, et. al., 2002] 16 Figure 31 Understand action research [Iversen, et. al., 2002] 17 Figure 32 Concept of action research [Kemmis and McTaggart, 1992] 21 Figure 33 Action Research evolution through cycles [Grane and Richardson,

2000] 22 Figure 41 eEngineering Transfer Model to the industry 24 Figure 42 Methodology for Technology Transfer 25 Figure 43 Generic project core process, activities and configurable subactivities 27 Figure 44 ASIS / TOBE process development assessment 28 Figure 45 Design and integration of environment and applications 32 Figure 46 Workflow based on the four domains of the Particular model for an

instance of Product/Process/Facility design 33 Figure 47 Connect applications of Customers and Suppliers 44 Figure 48 Performance Measures definition 49 Figure 49 Executed steps from Collaborative Environments Design 55 Figure 410 Workflow Reference Model [Hollingsworth, 1994] 57 Figure 51 Case studies: Performed Action Research Spiral 58 Figure 52 Integrated HighTech Product Development Process 61 Figure 53 Stages of Product Development process in the PHP CeEE 62 Figure 54 Php groupware architecture 64

Figure 55 PHPGroupware characteristics 65 Figure 56 Stages of Product Development process in freeware based CeEE..67 Figure 57 MSN™ collaborative tools (Messenger and groups) 69 Figure 58 Virtual Enterprise Broker projects 72 Figure 59 Installation/removal tool for airplane landing gear 73 Figure 510 Generic product transfer process based on the quality

documentation 74 Figure 512 Selected activity to exemplify the Environment design (Step III) 77 Figure 511 Product transfer TOBE 78 Figure 513 3D solid model of the Pickup tool 80 Figure 514 TOBE assessment for the selected activity 81 Figure 515 Workflow model for product transfer (in LotusWF ™) 82 Figure 516 Applications identif¡catión in the Product Transfer Engineering

changes activity 83 Figure 517 Information exchange in Engineering changes activity from Product

transfer process 85 Figure 518 Performance measures definition in engineering changes activity .86 Figure 519 CeEE architecture with WebSphere Technologies 87 Figure 61 Recommended sequencing for CeEE design 90

Ricardo Mejía Gutiérrez

LIST OF TABLES

Table 21 Collaborative Engineering Environments Review 14 Table 41 Computer applications Classification that supports integrated product

development 37 Table 42 Functional tools that supports integrated Product/Process/Facility

development 38 Table 43 Standardformats in common CAD systems 45 Table 44 CAD representations and some associated file formats 47 Table 45 Functionality needed after translation and the associated CAD

representations 47 Table 46 Performance measures Classification (Adapted from Zachman's

Framework) 53 Table 51 Legend for Methodology implementation in CeEE developments 59 Table 52 Computer applications for the PHPEnvironment Integration 63 Table 53 CeEE based on Freeware tools 68 Table 54 General activities in the Broker business opportunities Classification 71 Table 55 European Standard for case study RST profiles and their equivalences 79 Table 56 Case study Material and their equivalences 79 Table 57 CeEE based on WebSphere™ tools 84

ChapteM. Introduction

1.1 Background

The age of Information era and globalization has created a situation of increased International competition which has put manufacturing companies under augmented pressure in order to sustain and improve their market share. This has lead to more International collaboration within large companies or among different companies. Under this scenario the tasks of design and manufacturing of products are being executed by different facilities within a large company or by several different companies, usually at different geographically locations.

An example of this situation is happening between Latín America and the United States/European Union, where the design groups are in USA/EU and manufacturing facilities are located in Latín America. One of these cases is the automotive industry where systems and parts are distríbuted among 1 st Tler and 2nd Tier suppliers. For example a part is designed in USA and then the manufacture is transferred to Mexican companies [Acá, et. al., 2003].

1.2 Research justif¡catión

The special case of the North American Free Trade Agreement (NAFTA) has closed the relation between USA and México, especially commercial and industry relations. Today, Northern Mexican Región has been seen the installation of a large number of US manufacturing facilities looking for advantages in low cost labor, cióse to border localizaron and Mexican manufacturing expertise. The sectors with higher grow in the border are Electronic, Automotive and Power Industry [SECOFI 1999]. However, these facilities require transferring products in a more efficient and effective manner in order to reduce time to market.

Ricardo Mejía Gutiérrez

Problems faced between US and Mexican companies are lack of collaboration during early stages of life cycle product development, miscommunication between design and manufacturing engineers, poor access to Information manufacturing technological capacities and deficient knowledge of manufacturing process capabilities.

In order to support the manufacturing community of Small and Médium Enterprises (SMEs), the strategic programs as Virtual Industry Clusters [VIC, 2000] and Virtual Enterprise Broker [VEB, 2001] have been implemented. These programs support the development of SMEs through the use of information technology and the creation of valué added networks. Within these programs as well, groundbreaking work has been done in manufacturing, especially in life cycle engineering, collaborative product development, and SME clustering and brokerage, where the integration of these áreas, are the challenge for the next generation engineering work. Likewise, the world wide engineering requirements are demanding more than parts/components outsourcing and also engineering knowledge sharíng with their partners and allies, through an Integrated Product Development.

The concept of "Integrated Product Development" means the integration of all the activities, methods, information and technologies to conceive the complete Product Life Cycle" [Tipnis 1999]. Nowadays, several Computer based information systems have been introduced to support Integrated Product Development; however, there are two major technical challenges in computer supported group work:

• The applications have to enable the product development team to share, discuss and realize ideas.

• The envíronment and the collaborative applications integrated in these environments. The environment has to provide some services and to take care about the consistency and availability of data.

Based on these statements, a methodology to implement Collaborative e Engineering Environments (CeEE) will be proposed, providing a model to transfer the eengineering concepts to the industry. A taxonomy of supporting technologies for Collaborative Engineering is also proposed, and used as a tool for the applications integration into the environments design.

1.3 Objective and relevance of the research

Define a methodology to design and intégrate CeEE, in order to transfer the concepts of collaboration in engineering to the industry. The environment should intégrate computer applications which will support engineering activities for design and manufacturing in global product development.

Demónstrate the environments with improved scenarios based on the "Action Research" approach, in order test the methodology and improve it through reflections from cycling process improvement.

1.4 Scope of the research

There are five integrated eServices (as shown in Figure 11) that an engineering eHUB1 should offer as center for ondemand eservices for valué added industrial networks: eMarketing, eBrokerage, eEngineering, eSupply and eProductivity. The conjunction of these eServices will improve the competitive position of Latin American SMEs based on the Virtual Enterprise concept.

e Hoductivity

Figure 11 Integrated eServices offered by eHUBs [Molina, 2003]

An eHub is a Broker entity which act as an integrated engineering service provider through virtual capabilities of engineering and manufacturing

[image:18.575.162.432.426.633.2]Ricardo Mejía Gutiérrez

Brief descriptions of the mentioned eServices are:

• eMarketing to support the development of intelligent Webportals for promotion of producís and services of SMEs.

• eBrokerage to underpin the exploitation of business opportunities for the creation of supply chains, integrated networks of microenterprises and Virtual Enterprises based on SMEs.

• eEngineering to establish environments that foster collaboration among engineering groups to support integrated product development

• eSupply integrales services related to efactory, elogistics for importing/exporting materials and products, supplier and customer relation management.

• eProductivity integrales technologies for the diagnosis, planning, evaluation and monitoring of SMEs.

The present research ¡s focused on the eEngineering services, defining a methodology for the design and integration of CeEE.

1.5 Thesis organization

The present research work is organized in six chapters. Chapter 2 reports relevant literature review of the state of the art in Collaborative Engineering. It starts presenting the tendencies on simultaneous and remote engineering, and finally brief descriptions of collaborative environments from woridwide research groups are analyzed.

Chapter 3 describes the research methodology, which is based on "action research". A definition of this type of methodology is described, and analyzed in order to clarify the way the results were achieved, through the experiences developing CeEE.

The Chapter 4 presents the proposed methodology for design and integration of CeEE in order to transfer eEngineering practices to Industrial projects. The methodology is an improved set of steps resulting from the evaluation cycles from action research.

On Chapter 5, a description of the experiences developing CeEE with different technologies ¡s presentad. The progress and evolution is shown from one scenario to the next one, thorough the use of the proposed methodology ¡n these scenarios.

The Chapter 6 summarizes the results and conclusions of the experiences in developing CeEE, through action research improving cycles.

Finally at the end of this thesis a group of appendixes are presented, where Appendix A presents the detail of the reviewed "Collaborative Environments" analyzed ¡n the Literature Review. Appendix B explains each of the categories proposed in the taxonomy of Computer applications and tools to the integration of applications in CeEE. Appendix C is the a description of the most common exchange formáis on engineering design, followed by the Appendix D which presents detailed Information from the Process domain from Landing Gear case study. Finally the Appendix E contains the explanation of the IBM WebSphere™ technologies.

Ricardo Ate/Va Gutiérrez

Chapter 2. Literature Review

2.1 Introduction

Engineering design can be defined as the systematic, intelligent generation and evaluation of specifications for artifacts whose form and function achieve stated objectives and satisfy specified constraints [Dym and Little, 2000], these artifacts are most often "physical", like airplanes, wheelchairs, ladders, and carburetors. But they can also be "paper" products, such as drawings, plans, computer software, articles, and books. The form or the artifact is its shape, its geometry. By function we mean those things the artifact is supposed to do. The specifications of artifacts are precise descriptions of the properties of the object being designed. Typically they are numerícal valúes of performance parameters (e.g., constants or variables that serve as indicators of the artifact's behavior) or of attributes (e.g., properties or characteristics of the artifact). As a matter of terminology, we will refer to design specifications as that set of valúes that articúlales what a design is intended to do. Design specifications, then, also, provide a basis for evaluating proposed design, as they become the "targets" of the design process against which we can measure success in achieving them.

For hundred of years, the way of doing things was trough physical labor, in which a person with hand tools used craft skills to make objects. Since the industrial revolution, machinen/ has played an increasing role, but In more recent decades, the technologies have become more end more important, like computer aided design and manufacturing (CAD/CAM) and new concepts in quality assurance (QA). It is expected that the 21st century will bring even better process models, more exacting control, and ¡ncreased integration, through computer technologies and virtual integrations as shown in Figure 21:

Past, Present and Future

Early 18thCentury 19thCentury 20th Century 21th Century

A person with an anvil and a hammer Poorly understood process Craftspeople Cottage ¡ndustry Steampowered machinery Improved understanding of process Factory conditions ¡n cities Computer aided design, planning, and manufacturing Limited process models using closed loop control Increased factory automation Systemwide networks and information Robust processes and intelligent control Global enterprises and virtual manufacturing corporations

Figure 21 Tendencies to 21st Century engineering and manufacturing

[Wright, 2001]

The present trends created by the Internet have now set the stage for an even larger scale or global approach to manufacturing. We can expect to see global networks of information and distributed engineering and manufacturing enterprises. The Internet is certainly providing the infrastructure for these more flexible and informal ways of creating new enterprises that respond to people with a naturally entrepreneurial spirit.

Another important issue is that a successful design is not something that just happens. Rather, it is the result of careful thought about what customers demand, and the specification of ways to realize those requirements. There are various tools and techniques that assist the engineers in this design process. A particularly important element of successful design ¡s managing the design project. Just as thinking about design in a rigorous way doesn't imply any loss in creativity, using formal (and informal) tools to manage the process doesn't mean that we give up either technical competency or inventiveness. [Dym and Little, 2000] On the contrary, we can see many examples of organizations that foster imaginative engineering design as an integral part or their management style.

[image:22.579.117.499.83.306.2]Ricardo Mejía Gutiérrez

2.2 Market analysis

The manufacturing tendencies reflect the changes on the customer demands over the years. Nowadays, the market is constantly requiring more customized producís, moving from mass production, through mass customization until "one ofakind production" in less time with lower costs. These changes imply more flexibility, giving more importance to reconfigurable systems (ondemand)

A new competitive environment for industrial products and services is emerging and ¡s forcing a change in the way manufacturing enterprises are managed. Competitive advantages in the new global economy will belong to manufacturing enterprises, capable of responding rapidly to the demand of high quality and highly customized products [Molina; 1998].

Operating new competitive firms is becoming more difficult as product variety and options increase, product complexity increases, product life cycles shrink, and profit margins decrease. In addition, the capital costs of manufacturing technologies are extremely high. These factors impose high productivity levéis for manufacturing facilities. There is also the need to créate the next generation manufacturing systems with higher levéis of flexibility, allowing these systems to respond to very dynamic markets demands [lacocca Institute; 1991].

Those market needs, have been driving the manufacturing technologies through different concepts as customization, flexibility and business strategy. As a consequence, the term Next Generation Manufacturing (NGM) refers to the application of new concepts, models, methodologies and Information technologies, with the goal of preparing companies to become more competitive in a global and networked environment [Molina and Bell, 2002].

2.2.1 From traditional engineering, to Collaborative Engineering

The product design in industry is an activity where collaboration is fundamental. Indeed, many actors collaborate to achieve a common goal: The definition of a product that can be used and may be sold [Riboulet et. al., 2002]. At the same time the globalization of the industrial activity and decentralization of many manufacturing processes leads companies to work in relation to very distant collaborators as shown in Figure 22.

I*

A na ly sis

Supplier Assembly

Figure 22 Global product development [Molina, 2003].

In this context collaboration must be organized to allow a better communication between actors. Concurren! engineering methodologies are developed in order to involve the different points of view on the product, all along its life cycle. This trend is pushed by the product's evolution: design of complex artifacts and systems requires the cooperation of multidisciplinary design teams providing optimization from any point of view.

Organizations are constantly seeking better methods for improving productivity and effectiveness in task accomplishment, prímarily through the use of technology management. Examples include the need to reduce the cost of designing new products and to significantly shrink overall development life cycles [Bochenek and Ragusa, 2001]. The most common use of Collaborative e Engineering Environments (CeEE) is currently in collaborative design, education and training.

2.2.2 Industry background

In industrial cases, specially in large projects, physically colocated meetings are often expensive, impossible to manage and may be of poor efficiency. So the expansión of Intemetbased tools has opened new opportunities for collaborative

Ricardo Mejía Gutiérrez

work improvement. This can explain the development of a new generation of tools designed to support this kind of activity: Internet/Web and CSCW (Computer Supported Cooperative Work) in design. [Riboulet et. al., 2002]

An everincreasing number of organizations are beginning to use virtual environment tools for product development. These systems are characteristically 3D computer graphic systems with realtime user interactive control and viewer centered perspectives. However, the use of virtual environments technologies raises severa! virtual CeEE operational and research issues that need identification and investigation.

For example [Keller, 1998] the Boeing Corporation used ComputerAided Threedimensional Interactive Application (CATIA) software to reduce by 60 to 90 percent design rework for its 777 aircraft. Various auto manufactures have also experienced substantial improvements and acceleration in vehicle styling and design made possible through the use of CeEE.

Another example, DaimlerChrysler Corporation's Dodge Intrepid product line was developed using what the company calis "cyber synthesis" that resulted in five new vehicles and three new V6 engines. As a result of the use of Virtual Environment technologies and digital models, the company has reported cost savings of $75 million and a 20 % reduction in its intrepid model development time. [Bochenek and Ragusa, 2001]..

2.3 Collaborative Engineering Environments

A Collaborative eEngineering Environment (CeEE) is an automated environment that enables people (including sales, designers, engineers, managers, and customers) to collaborate and interact on the development of a new project regardless of their geographic locations and interaction means [Shen, 2003]. With the advances in Information and communication technologies, particularly Internet and Webbased technologies, Collaborative Engineering has been recognized as a promising médium for complex engineering design projects.

CeEE establishes and manages a collection of virtual workspaces, each of which incorporales people, ¡nformation, and engineering tools appropriate to a design activity. In a CeEE users can particípate in several workspaces, discover collaboration opportunities, provide knowledge or services, seek information or assistance, and perform their design activities. In this kind of environment, knowledge sharing among people as well as software tools is imperative to support collaborative design activities efficiently and effectively

Knowledge in a CeEE must be well organized and should be flexibly applied to different kinds of design problems. Integrated knowledge bases may suffer from the lack of uniform knowledge representation. There are many different views of a design (e.g. function, performance, and manufacturing), each with a different language, and various perspectives, typically overlap, necessitating the sharing of information if a design is going to be executed concurrently and cooperatively. Some research in this área is related to various áreas and technologies including AI/DAI, knowledge engineering, databases, Computer Supported Cooperativo Work (CSCW) and groupware, as well as Internet/Web based technologies.

The compelling story of the development of engineering HUBs then becomes the delivery of a new service (filling a gap in existing collaboration technologies whose focus is primarily on operation collaboration support). The core service of the system will be largely a web hosted Integrated product development space, augmented by the right mix of technologies and additional services and offering a backend connection to a set of operational collaboration platforms.

2.3.1 Context

A conceptual virtual collaborative design environment model, shown in Figure 23 ¡Ilústrales the interrelationships between people, work, and technology within the broader context of organizational social, and technical environments [Bochenek and Ragusa, 2001]. Selecting an appropriate tool or integrating advanced technologies to support the process of team product design evaluation or the overall organizational goal to reorganize the design, development and acquisition process, requires that all conceptual model elements be considered individually and together. The model helps to consider how these elements affect and ¡nfluences organizational Virtual Collaborative Design Environments

operational and research issues for new product and system design analysis.

Ricardo Mejía Gutiérrez

Figure 23 A Virtual Collaborative Design Environment conceptual model [Bochenek and Ragusa, 2001]

A. Organizational, Social, and Technical Environments: The organizational environment is primarily defined by the goals and objectives of the organizaron, (e.g. whether profit seeking or not). The social environment is determined by how the organizaron functions with regard to the degree of individual and team interaction cohesiveness and motivation that exists to accomplish work. The structure of the organizations, e.g., functional, project, or matrix affects the social context of activities performed. The technical environment is driven by the degree to which the organization is dependent on and supports technology.

These environments, individually and collectively, influence a set of factors that directly affect the environment design considerations. Within these factors the importan! relationships are between people and the work tasks they perform, and between people and the technology they use to accomplish work.

B. Work: Product Design, Development, and Simulationbased Acquisition C. People: Integrated Product and Process Teams

D. Technology: Immersive, Interactive Virtual Environment (VE) Tools

The dramatic growth ¡n the World Wide Web has also seen a rapid increase in the range of distríbuted cooperative applications. Many of these move beyond the existing clientserver model of interaction that underpins World Wide Web, to support much richer pattems of user interaction and activity [Tian and Taylor, 2001]. While often exploiting their own distríbuted infrastructure, these environments seek to build upon the accessibility and coverage of the World Wide Web to promote and support a number of geographically remote users working together.

2.3.2 Relatad research

During the last years, many researches have focused on the technologies or the infrastructure that can assist product designers in the distríbuted design environment. Some examples are CAD conferences, work process modeling and management, product data sharing, agentbased knowledge sharing and conflict management. These ongoing research efforts aim the ways in which a diverse group of product designers and computerbased design tools or systems can work together in a networkoriented environment. A few examples of these efforts would be explained as follows [Chung and Lee, 2002]:

• CAD conferencing: enables synchronous collaborative work due to its geometry models exchanging capabilities and the teleconferencing system. The research is focused on application sharing, coauthoring, 3D visualizaron and desktop conferencing.

• Work process modeling: supports asynchronous collaboration among workgroups by modeling and managing design workflow to enable complex design procedure to be handled efficiently.

• Product data sharing: for collaborative design, the efficient exchange and sharing of product data through the product lifecycle is important.

• Agentbased knowledge: focused on enabling collaboration among software agents for supporting design teams in sharing their understanding of the design process.

• Conflict management: enables to coordínate information for collaborative design. Some coordination strategies to avoid conflict between design participants have been proposed.

Therefore, an analysis of the state of the art in Collaborative Engineering Environments was carried out, in order to compare and find convergence among different approaches from several research groups. Due to this, some specific research projects in simultaneous and collaborative engineering will be briefly described in the Appendix A from this thesis, and simplified in the Table 21 from this chapter, in order to understand the basis for the development of this kind of environments in collaborative engineering.

The projects Domain will be mapped according to the taxonomy proposed on the Section 4.3.2 of this thesis for the classification of computer applications to support product development (See also Appendix B).

Ricardo Mejía Gutiérrez

The categories from the Taxonomy are: • F: Functional tools

• Cd: Coordination tools • Cl: Collaboration tools

• KM: Information/Knowledge management tools

This will guide the analysis to determine the main área where researchers are focusing on, or to determine the kind of tools that researched environments integrales.

Table 21 Collaborative Engineering Environments Review

Group Molina, et. al., 1995

Hanneghan, 1998

Huang, 2002 Qina, et. al., 2003

Tay and Roy, 2003

Heckel, et. al., 1997

Chlebus, et. al., 1998 Oliveira, 2003 dVISE, 1999 Wanga, 2003 Mitschang, 2003 PIVOTAL, 1999 Tamine and Dillmann, 2003 Harrison, 1996 Huang and Mak, 2002 Qian and Shensheng, 2002 System MOSES CONCERT CyberReview Webbased conceptual design CyberCAD VWS PDMTech Epistheme dVISE WebBlow TOGA and CHAMPAGNE PIVOTAL KaViDo Deneb CyberCO P.PROCE Description

A source of product and manufacturing Information, with an Engineering Moderator Allows virtual team members to access these middleware setvices via the Internet through crossplatform applications

A central portal for supporting collaborative product design review

2D and 3D geometríes sketching, manipulation and simulation (not standard CAD systems)

Webinteractive CAD software

Provides a service for sharing state for asynchronous collaborating engineering applications

Support every organization of data management and process structure The exchange, share and dissemination of knowledge

Product data visualization and simulation. Allows real time visualization to interact and redline 3D models

Share product Information and knowledge, and to ensure the system security

Exploits common work and information spaces

3D models manipulation, discussion and collaboration facilitated

Record and document development processes

Enables realtime, Interactive collaboration They are agents and workflows

Product development process management system that integrates WFMS with PDMs

Based on the performed review about Collaborative Engineering, The author has noticed:

• That most of the collaborative environments or tools are functional oriented applications, trying to support specific activities within the Product lite cycle. Likewise, the major emphasis ¡n the collaboration research lines ¡s the CAD/CAM/CAE.

• The research efforts are mainly softwaredriven. That means the researchers are more concemed with the technical issues, more than evaluating the overall Engineering Environments.

• Researches are more focused on the development of their own technologies, developing new software tools more than integrating existing ones.

• A remaining open issue is to cover the whole life cycle, trying to intégrate standard tools combining the different need from the actual globalized markets.

It is important to consider that the impact of design decisión is initially very high, and declines steeply as the design matures. Great opportunity exists at the preliminary design stage, and the literature review has shown more research interests in advanced stages of product development, where the amount of technologies is bigger than the available tools for early stages. Therefore, directing the efforts to an integrated product development, considering as well the early stages, will have considerable impact on the decisión making.

As shown in Figure 24 the opportunities in collaborative Engineering will be leaded by the integration of tools, not only form advanced stages, but also from early stages in order to have an increased impact and a major coverage of the product life cycle. However, the tools from advanced stages may not be forgotten.

Ricardo Mejía Gutiérrez

(O

c

o £

i

o•5

§

Conceptual

Design ProductionDesign

Figure 24 Opportunity ¡n early design stage [Wang, et. al., 2002]

Finally, the collaborative coordination tools seems not to be widely spread into the Collaborative Engineeríng approaches, and this is an important issue to be tackled. There are just a few environments which consider the management issues. Thus, another opportunity can be the coordinating automation in Collaborative Engineering Environments.

As a result, this research work intends to tackle the major issues already mentioned in this analysis. It can be achieved designing integrated environments, where workflow and methodologies formalize engineering lifecycle activities, balancing the methods and tools, and also considering if there are needs to design Products / process / Facilities. The integration of computers applications leads collaboration and interaction among different partners, and finally, the use of standard tools will be pursued, in order to focus the efforts more in the integrated definition, than specific detailed software problems. The idea is to genérate integrated solutions for the industry, more than creating software applications and tools for the market.

Chapter 3. Research methodology

3.1 Introduction

The development of the current research work was carried out using leaming cycles, where lessons leamed from previous ¡terations (based on experiences) allowed the improvement and changes to the current work execution in e Engineering. This kind of research concurs with an already defined research methodology called: Action Research.

Action research consists of a family of research methodologies which pursue action and research outcomes at the same time (See Figure 31). Under this approach, the author of this research work was able to propose an improved methodology for the design and integration of CeEE which will be detailed in the next Chapter. The current Chapter will give an introduction and explanation of the general concepts of Action Research in order to understand how it works and to clarify the results achievement of this work.

Action

Research

Problemsolving that is not designed, executed, and assessed as an integral part of a research effort

Research that does not include design, execution, and assessment of a problem solving effort

Action research, i.e. research that includes and is mainly based on practical problem solving

Figure 31 Understand action research [Iversen, et. al., 2002]

Ricardo Meji'a Gutiérrez

As an introduction, several defini'tions for action research exist. Some of them are presented:

Action research..."aims to contríbute both to thepracticalconcerns of people in an immediate problematic situation and to the goals of social science by joint collaboration within a mutually acceptable framework." [Rapoport, 1970].

"Action Research is a process by which change and understanding can be pursued at the one time. It is usually described as cyclic, with action and critical reflection taking place in turn. The reflection is used to review the previous action and plan the next one."

[Dick, 2000].

"Action research is undertaken by participants in social situations to improve their practices and their understanding of them." [Bowling, 1997]

"Action research is collaborative, critical and selfcritical inquiry by practitioners (e.g.: teachers, managers) into a major problem or issue or concern in their own practice. They own the problem and feel responsible and accountable for solving it through team work and through followinga cyc//ca/prac//ce"[ZuberSkerrit, 1996].

Conventional experimental research has developed certain principies to guide its execution. These principies are appropriate for certain types of research, but they can actually inhibit effective change in some cases. Action research has had to develop a different set of principies. It also has some characterístic differences from most other qualitative methods [Dick, 2000]. Action research tends to be:

• Cyclic: Similar steps tend to recur, in a similar sequence;

• Participative: The clients and informants are involved as partners, or at least active participants, in the research process;

• Qualitative: It deals more often with language than with numbers; and • Reflective: Critical reflection upon the process and outcomes are important

parts of each cycle.

3.2 What is action research?

Action research is a flexible spiral process which allows action (change, improvement) and research (understanding, knowledge) to be achieved at the same time [Dick, 2002]. In most of its forms it does this by

• Using a cyclic or spiral process which alternates between action and critical reflection and

• In the later cycles, continuously refining methods, data and interpretaron ¡n the light of the understanding developed in the earlier cycles.

In most of its forms it is also participative (among other reasons, change is usually easier to achieve when those affected by the change are involved) and qualitative. It is thus an emergent process which takes shape as understanding increases; it is an iterative process which converges towards a better understanding of what happens. The understanding allows more informed change and at the same time is informed by that change. People affected by the change are usually involved in the action research. This allows the understanding to be widely shared and the change to be pursued with commitment.

Action research commonly proceeds like this: The researcher plans the first or next step and is then carried out. Researchers meet to recollect and critique their experíence. In the light of this, they decide what to do for the next step (what information do they need or what outcome to pursue, and what method to use). In short, action research alternates between action and critical reflection. The reflection consists first of analyzing what has already happened in previous steps, and then of planning what next step to take.

Action research aims to contribute both to the practica! concerns of people in an immediate problematic situation and to the goals of social science by joint collaboration within a mutually acceptable framework. In most of its forms it is also participative (among other reasons, change is usually easier to achieve when those affected by the change are involved) and qualitative. It is thus an emergent process which takes shape as understanding increases; it is an iterative process which converges towards a better understanding of what happens. (Dick, 1999)

Ricardo Mejía Gutiérrez

It is true that action research and some forms of practice are in some ways similar. Both are often directed towards the achievement of change. Both are qualitative and often participative. Both tend to be flexible and cyclic. In both instances, there is a desire to base planned changes in the situation on understanding, and to derive that understanding from evidence.

3.3 Action research cycles

With the exception of wellpracticed tasks there is a natural rhythm to the way most of humans behave. They do something, and then they check if it worked as expected. If it did not, is analyzed what happened and what they might do differentiy. If necessary the process is repeated (act > review > act > review

and so on)

Most writers on the topic state or assume that action research is cyclic, or at least spiral in structure. One crucial step in each cycle consists of critical reflection. The researcher and others involved first recollect and then critique what has already happened. The increased understanding which emerges from the crítica! reflection is then put to good use in designing the later steps.

The well known cycle is that of Stephen Kemmis [Kemmis and McTaggart, 1992]. According to them, action research occurs through a dynamic and complementary process, which consists of four essential "moments": of Planning, Action, Observation and Reflection. These moments are the fundamental steps in spiraling process through which participants in an action research group undertake to:

• Develop a plan of crítically informed action to improve what is already happening,

• Act to implement the plan,

• Observe the effects of the crítically informed action in the context in which it occurs, and

• Reflect on these effects as the basis for further planning, subsequent crítically informed action and so on, through a succession of stages

Kemmis and McTaggart's concept of action research is set out in figure 32:

Figure 32 Concept of action research [Kemmis and McTaggart, 1992]

The reflection leads on to the next stage of planning. The "planning" isn't a sepárate and prior step; it is embedded in the action and reflection. As change is intended to result, effective action research depends upon the agreement and commitment of those affected by it. This is usually generated by involving them directly in the research process. In many instances, researchers try to involve them as equal partners.

Cycles provide a useful way of thinking and describing an Action Research process. Researching a particular issue usually involves going through a number of cycles. This allows practices and understandings to be refined or changed over time. It may mean also that the analyzed issues needs refinement or change.

Ricardo Mejía Gutiérrez

The diagram on Figure 33 shows the way Action Research evolves through cycles of planning, action, observation and reflection. The rising base line represents the goal of continuous improvement. Successive cycles become larger and represent the way that the process may change over time.

Observe /"

Reflect

Act

Plan

Figure 33 Action Research evolution through cycles [Grane and Richardson, 2000]

The author of this thesis proposes a methodology for the design and integration of Collaborative eEngineering Environments. The basis approach to the design of the methodology was to use action research as a mean of ensuring the success of the methodology, through an evaluated set of steps, and with the required technologies to allow its implementation. In Chapter 5 of this thesis, an explanation of the evolution in the experiences developing Collaborative Environments is shown, noticing the cycles proposed by the action research approach. However, the action research as a research methodology was not fully applied. Only the overall concept and the main steps were mapped to the current thesis development. The next Chapters explain in detail, the refined methodology, achieved by the enrichment during the experiences cycles.

Chapter 4. Methodology for design and integration

of Collaborative eEngineering Environments

There are several technical challenges in Collaborative Engineering: 1) Definition of a Collaborative Integrated Product Development process among the different companies participating in Product Life Cycle activities; 2) Establishment of environments that foster the coordination and cooperation among engineering groups and, 3) Integration of applications and tools that allows the exchange of information and knowledge among engineers in an effective and efficient manner.

Therefore Collaborative eEngineering Environments, with an underlying methodology, must be designed and developed to train and cultívate "Communities of eEngineering Practice". These integrated environments must enforce four dimensions of eEngineering:

• Process: how engineering (design, manufacturing, supply, procurement and service) is realized in a global environment using etechnologies.

• Information: how information have to be structured and shared between all the engineering teams in a global eEngineering environment.

• Organizationah how cultural diversity and behavior affects global engineering activities and how teams can be organized based on core competencies to achieve global eEngineering.

• Technology, how different etechnologies and eapplications can be integrated to achieve global eEngineering.

Likewise, the proposed methodology intends to overeóme the major issues mentioned in the literature review analysis, as a lack of the nowadays research efforts. The proposed methodology in this thesis foster Collaborative environments integrating tools not only functional oriented but also platforms to achieve coordination, collaboration and information management capabilities.

Ricardo Ate/Va Gutiérrez

The integration of standard tools ¡s the main focus, more than developing own technologies. The integrated visión of collaborative concepts enforces collaborative support to cover the whole engineering life cycle, from early stages, to advanced ones, where a large number of computer tools exist.

Consequently, a methodology has to be followed for the integration of Collaborative eEngineering Environments in order to be transferred to the industry to support cooperative groupwork in engineering services. Henee, the next sequence of activities is proposed, as shown in Figure 41, as the e Engineering Transfer Model to the industry:

II

Determine the Company process

requirements

y » y—irm

Model Revisión

Model

Assessment

Model Evaluation

IV

Execute and manage the Environment

lüh

Assessment of the AS IS, and model

the TOBE

Model Implementation

III

Model Execution

Design and Integration of Environment and

applications

Figure 41 eEngineering Transfer Model to the industry

The model starts with the identif¡catión of the current Industry's development process. It can be determined based on reference models2 for the type of process development definition. This process is considered ASIS.

2 The Chair in Mechatronics from the Integrated Manufacturing Systems research Center, from

the Monterrey Institute of Technology (CSIMITESM), ¡s currently working on the development of reference a model for reconfigurable Product, Process and Manufacturing systems development processes.

A graphical representation of an ASIS model can be done and from this base, it is possible to propose a TOBE process model. The flexibility of using a graphical representation helps identifying duplicated information, parallel activities and information sent to other departments in order to become more efficiently. This TOBE process model will be the base to define the environment Workflow. Sometimes the ASIS does not exists, or it can be directly the TOBE. This can happen when improvements are already considered in the current process, or when new work methods are proposed to be implemented in Industry.

A Workflow Model of Integrated Process Development is then built, based on the identified activities, which are required for a specific design process (particular model). In order to genérate a complete and reliable workflow it is necessary to have a specific understanding and environment identif¡catión from each activity based on the input process model.

The Figure 42 shows the steps defined in the eEngineering Transfer Model, which will be detailed in the following sections:

• I. Determine the Company process requirements (ASIS)

D Product n Process

LJ Manufacturing system

• II. Assessment of the AS IS, and model the TOBE

o Process and information ftow u Human resources / Teamwork o Data Information Knowledge D Technology / Methods and techniques

• III. Design and integration of environment and applications

u Model (Modeling the workflow)

D Intégrate (Selection and Integration of eEngineering applications) ] Connect (Connect environment and applications)

n Monitor (Definition of performance measures)

IV. Execute and manage the CeEE • " . • " • '' •''"'•

Figure 42 Methodology for Technology Transfer

Ricardo Mejía Gutiérrez

4.1 Step I: Define the company requirements and model the AS

ÍS of the development process

In order to understand the context of process development, an engineering project can be divided into activities and subactivities. According to [Mejía and Molina, 2002], a project ¡s carried out going through four core processes: Market requirements, Project planning, Project execution and Customer followup. In the project executíon stage, it has been considered important to follow the model of Integrated Product Development where the Broker has to carry out four main activities [Cooper, 1993]: Ideation, Basic Development, Advanced Development

and Launching.

Even though, the activities from project execution may vary depending on the type of development process. A reconfigurable methodology for product, process and manufacturing systems development has been developed [Molina, 2003], allowing the project planners to know in advance, what stages has to be performed by the project team. Into the methodology, information technologies and resources are identified and considered, as well as severa! methods and techniques and their corresponding inputs and outputs.

The Figure 43 depicts the integration of the project core processes, with the possible project execution configurations. When a project is going to start, at the project planning stage the methodology is then configured with the corresponding stages and the necessary activities, in order to fulfill all the project requirements to accomplish a successful project execution with high quality results and with less time of development.

Analyzing the ASIS business process model provides the knowledge and foundation upon which all process design, improvement, and redesign decisions are based and allows the design team to represent graphically how a process is executed, so that the process is understood and agreed upon by all involved. The ASIS business process model is then, the representation of the current processes, prior to any improvement ideas.

Customer followup

Product 1 Design

Process [ Design J

Manu facturing

System Design

\ Project YV Basic / Definltion // Development

Product Idea Individual Componen! Specifications Product Transfer Technology Transfer Facility Desígn Individua l Componen ) Speclflcatlon s Conceptual Design & Target Specifications Process Selection

Manufacture partner or Supplier Selection

Equipment Selection

Concept Design & Target Specifications

\

/

v\ Advanced

' / Developrnent

Detailed Design Operation Planning Manutacturing & Quality Control Manufacturing Layout Design Detailed Design \ / \ >

y y Launching / /

Prototype

Ramp up Productfon

Componente

Setup Equipment

Facility constructton & Setup

)

Figure 43 Generic project core process, activities and configurable sub activities

4.2 Step II: Assess the AS IS, and model the TOBE

As mentioned before, an ASIS model is defined; However ¡t can be no ASIS model depending on the company's requirements. Afterwards, the TOBE process is modeled capturing the processredesign team's analysis or it can be a proposed methodology, when there is no current process in execution.

The product lite cycle under an Integrated Product Development requires a process model which must be integrated with an efficient information/knowledge management (not only the physical product features, but also the information/knowledge flow from the different departments and the integration among them), as well as the human resources involved (also with the hierarchy and responsibilities for specified tasks), and finally the Technology that will be used (application/tools for required methods and techniques) where the computers applications has priority in the Identification, in order to analyze their integration in the collaborative environment.

Ricardo Ate/Va Gutiérrez

Henee, there are four domains in the identification of the integrated product development environment: process, information/knowledge, organization and resources; which are defined in the following sections, and depicted in Figure 4 4, adapted from [AIAshaab, et. al., 2000]:

Product Information Manufacturing

Information

Data mmsm Information

«sx^imiipps»»—

Knowledge

Technologlcal Resources Methods Techniques

Y

Identification of keypeople

APPLICATIONS & TOOLS

Collaboration Knowledge/Information Management

Figure 44 ASIS / TOBE process development assessment

4.2.1 Process Domain

By modeling the product development activities by the process domain view, it is possible to:

• Describe the activities of the Integrated Product Development • Identify the flow of information through the product life cycle

• Recognize the resources, controls inputs and outputs incorporated in each activity

• Select the core processes and activities of a company

The process modeling is one of the basic ways to understand how a project is carried out. The integration of a company (or group of companies) among

different activities and áreas ¡s also represented ¡n this process domain. By analyzing the project process, it ¡s possible to understand the relations between partners, departments, áreas, Information, resources and materials. Commonly these relations are not identified by the companies, reason why a graphical representaron (based on the reconfigurabie methodology) will help.

The Process Domain will establish:

• The structure of the activity modeling

• The resources used in each activity (Human and Technological) • The teams that support specific activities

• The controls based on the current company's tools

4.2.2 Information /Knowledge Domain

The Information/Knowledge Domain allows the detailed description of data, information and knowledge required in the integrated product development, making possible to:

• Segment the available information into: Data, Information and Knowledge • Structure the product Information

• Structure the Manufacturing information

• Identify the engineering relation between product and Manufacturing elements.

• Identify the sources of Data/1 nformation/Knowledge

The evolution of information modeling methodologies has reached an important level up today. These methodologies had been oriented to aspects related with the product's life cycle [Molina and Bell. 1999]. The information required throughout the life cycle of a product can be described, structured, stored without redundancy and standardized if the relevant data concerning a company, its products and manufacturing facilities is defined in information models [Weck et. al. 1991].

In this Information domain, the data/information/knowledge structure must be considered, in order to define the starting specifications for a PDM structuring. This is the way that information will be stored in a specific datábase for further consultation and also to track the information generation.

Ricardo Mejía Gutiérrez

In order to represent the information domain, ¡t is necessary to specify which Information of the models would be necessary and which structure will be required based on the general structure of information models:

• The Product Modeling: Representing all the information related with the products and components at all the stages of the product's life cycle.

• The Manufacturing Modeling: Representing information modeling from the manufacturing processes, resources and strategies in a company.

Both Models are considered in the information domain in order to cover the complete product information (product process production facility) and to establish the framework for information structuring. Likewise the Information Domain uses data and information from the technological resources as a reference, to establish the level of integration and connectivity required in the future CeEE integration.

4.2.3 Organization Domain

The identificaron of the human resources and how they are organized is defined within the Organizational domain. It must establish the relations among the areas/departments/partners involved ¡n a simultaneous engineering (concurrent engineering) environment. The organization structure is important, in order to identify the key players in the engineering activities, not only for execution, but also for reviewing, supervising and monitoring. A fíat organization helps the integration with suppliers and customers, following the extended enterprise concept.

In the organization domain, is important to consider the partners roles, in order to specify the possible interactions, as well as the knowledge and information sharing, which will be critical for some design activities. For these considerations, the knowledge and skills from the people is a key issue for the resources assignment to specific tasks and activities.

About the human organization is preferred to have a fíat organizational enterprise structure, in which a less authority levéis organization is proposed. This type of organizations forced the companies become more agüe and tends to centralize more responsibilities in working teams as well as reduces bureaucracy,

![Figure 11 Integrated eServices offered by eHUBs [Molina, 2003]](https://thumb-us.123doks.com/thumbv2/123dok_es/4453249.35490/18.575.162.432.426.633/figure-integrated-e-services-offered-e-hubs-molina.webp)

![Figure 21 Tendencies to 21st Century engineering and manufacturing[Wright, 2001]](https://thumb-us.123doks.com/thumbv2/123dok_es/4453249.35490/22.579.117.499.83.306/figure-tendencies-st-century-engineering-manufacturing-wright.webp)