Methodology to Design Reconfigurable Manufacturing Systems

Texto completo

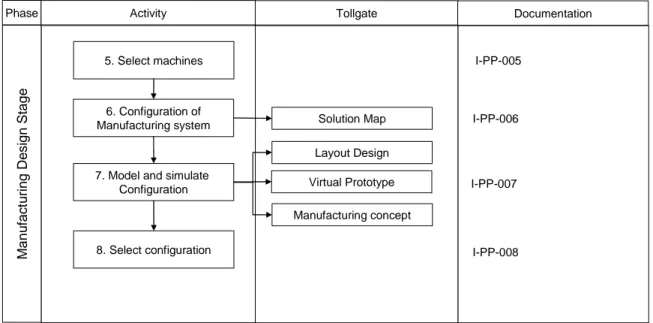

Figure

![Figure 3-1 Framework for the reconfiguration of manufacturing systems (adapted from [Wu 2001])](https://thumb-us.123doks.com/thumbv2/123dok_es/2276556.514409/13.918.173.749.105.545/figure-framework-reconfiguration-manufacturing-systems-adapted-wu.webp)

![Figure 3-2 Representation of the Methodology to Design Reconfigurable Manufacturing Systems, adapted from [Aca 2003]](https://thumb-us.123doks.com/thumbv2/123dok_es/2276556.514409/16.918.139.786.468.902/figure-representation-methodology-design-reconfigurable-manufacturing-systems-adapted.webp)

Documento similar

The extended HW/SW architecture of the Door Status Control main function includes all the nominal design decisions in the functional model (i.e., EDD, EDP, DCC, DOC, DOD, DCD, DV,

As opposed to systems that merely assemble records, the design of the applications in Diraya shared tables, codes and catalogues; (b) To create the Bioinformatics Research Area [82],

To this end, a Box-Behnken Design was carried out to study the influence of the curcumin amount, the structurant concentration and the manufacturing temperature on the oxidation

[r]

Frank Schweitzer, Risk Center and Chair of Systems Design, ETH Zurich.. Dr David Garcia, Risk Center and Chair of Systems Design,

Government policy varies between nations and this guidance sets out the need for balanced decision-making about ways of working, and the ongoing safety considerations

In this case using Design for manufacturing, the material and the manufacturing process used to make the product will be identified to simplify the design of

The environmental impacts affecting human health during the life cycle of the solvents used in perovskite film 194.. manufacturing, including production, removal and EOL for the

![Table 3-2 Applications and tools that support the design for reconfigurable manufacturing systems [Mejía 2004]](https://thumb-us.123doks.com/thumbv2/123dok_es/2276556.514409/21.918.144.789.231.842/table-applications-support-design-reconfigurable-manufacturing-systems-mejía.webp)

![Figure 2-1 The life-cycle concept of product design [Alting, 1993].](https://thumb-us.123doks.com/thumbv2/123dok_es/2276556.514409/33.918.301.615.553.867/figure-life-cycle-concept-product-design-alting.webp)