Assessing the impacts of implementing lean construction = Evaluando los impactos de la implementación de lean construction

Texto completo

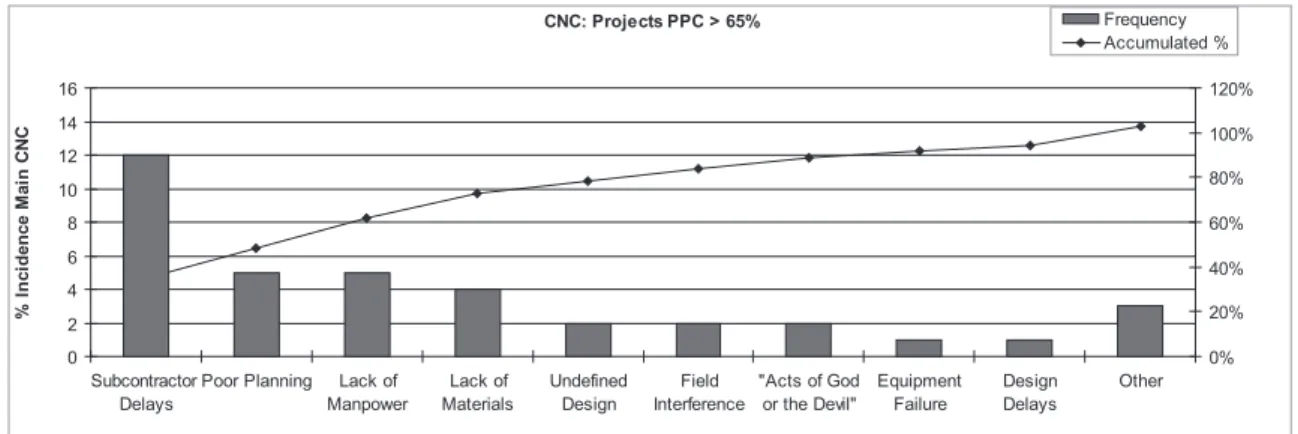

Figure

Documento similar

of these diagrams is guiding the construction of the soft- ware artifacts shown to the bottom of the figure: the transformation code (in any implementation language such as QVT or

Since we are mostly interested in scalar fields, the basic construction is enough for our purposes. There are no de Sitter invariant two-point functions and the construction of

The mission of the company is to offer an innovative product and service with quality, therefore it dedicates much of its efforts to the research and development of new

Firstly, it responds in some way to its historical and cultural moment: it is a work designed with a classical 19 th century construction methodology (through

Professional construction management refers to a project management team consisting of a professional construction manager and other participants who will carry out the tasks

After the construction of the different road sections, cores were taken at different periods of their service life (up to 63 months) and they were tested in the laboratory in order

Government policy varies between nations and this guidance sets out the need for balanced decision-making about ways of working, and the ongoing safety considerations

Line balancing and frequent time & motion study were found popular and suitable among the other lean manufacturing practices for the improvement in productivity,