Reference Model and Methodology to Improve the Product Development Process Edición Única

Texto completo

(2) INSTITUTO TECNOLÓGICO Y DE ESTUDIOS SUPERIORES DE MONTERREY CAMPUS MONTERREY DIVISIÓN DE INGENIERÍA Y ARQUITECTURA PROGRAMA DE GRADUADOS EN INGENIERÍA Los miembros del Comité de Tesis recomendamos que la presente Tesis del Ing. Nicolás Peñaranda Verdeza sea aceptada como requisito parcial para obtener el grado académico de Maestro en Ciencias con especialidad en:. SISTEMAS DE MANUFACTURA COMITÉ DE TESIS. _______________________________ Dr. Arturo Molina Gutiérrez Asesor. ___________________________ Dr. David Guerra Zubiaga Sinodal. ___________________________ Dr. Ricardo Ramirez Mendoza Sinodal. APROBADO. _______________________________ Dr. Francisco Ángel Bello Director del Programa de Graduados en Ingeniería MAYO de 2007. II.

(3) DEDICATORIA. A Mis Padres Por su incondicional apoyo y sus grandes enseñanzas, todo lo que soy y todo lo que he logrado es gracias a ellos A mi Hermana Por ser la persona que siempre me impulsa a ser mejor cada día y me da fuerzas para seguir adelante A Karla Por su amor incondicional, sin su gran apoyo mucho de lo que he logrado no habría sido posible A mi familia en Monterrey A la Sra. Adriana, Sra. Irene, Sr. Ramiro, Melisa, Vicky por ser esa gran familia aca en Monterrey, gracias a ellos me he sentido como en casa. III.

(4) Acknowledge Cátedra de investigación Núcleo de Innovación CEMEX-TEC y la cátedra de Investigación en Máquinas Inteligentes El desarrollo del presente trabajo de tesis ha sido apoyado con los fondos de la cátedra de investigación en Mecatrónica (CAT-006) y la Cátedra CEMEXBPM (CAT-031) del ITESM, Campus Monterrey. Al Dr. Arturo Molina Gutiérrez Por la oportunidad que me ha dado y las múltiples enseñanzas y experiencias a lo largo mi estancia en el Tecnológico se Monterrey Al Dr. David Guerra y al Dr. Ricardo Ramirez Por sus valiosos consejos para el enriquecimiento de esta investigación A Joaquin Aca Por sus gran apoyo, enseñanzas y por brindarme ese gran número de experiencias A todo el grupo de investigación e IECOS A Nathalie, Ricky, Luis Canché, David V., Luis M., David (Chino), David (Corredor), Luis Martelo, Pedro, Arturo, Pepe, Choche, Javier, Polox, Nanis a todos los de intercambio y muchas más personas que de alguna u otra forma estuvieron ahí brindándome su amistad incondicional. IV.

(5) Summary. Product development managers are looking for new ways to improve their product development process. Emerging concepts and solutions as Product Lifecycle Management (PLM), which is based on Concurrent Engineering (CE), carries out this improvements, achieving reductions in time and cost in the product development process. However, there is a lack of a particular reference model and methodology to achieve a successful PLM implementation within companies. Enterprise Integration Engineering (EIE) is a reference model that can be used to develop a particular reference model for the product development process. This reference model for product development aligns the enterprise strategies with the use of product development tools in order to impact key performance indicators in the company. Also, EIE reference model helps to define strategies, evaluate performance measures, design/re-design processes and establish the enabling tools and technologies. However, a reference model doesn’t have a methodology to implement systematically these changes in the company. For this reason, Action Research (AR) is used to guide the improvement of the product development process, proposing changes in the resources, organization, functional (process model) and information model. AR is customized, defining specific activities for each cycle developed. It is necessary to demonstrate this methodology using a case study, which is used to validate the benefits of this methodology proposed. This case study is developed in a Mexican company, which have the interest to improve its product development process. Final Conclusions are described based on the experiences in the implementation of this methodology. These conclusions are based on the technological and human resources, information, organization and functional changes developed in the case study. Current Technologies can reach a complete Product Lifecycle Management, however previous works are demonstrated that just implement technological resources do not guarantee an improvement of the product development. For this reason, in this thesis is highlighted the necessity to use a methodology that also propose changes in the company organization and product development activities. Finally, Impacts and benefits to implement these improvements are evaluated.. V.

(6) Contents. 1. 2. Introduction .................................................................................................................... 1 1.1. Research Problem .................................................................................................... 1. 1.2. Research Justification ............................................................................................... 1. 1.3. AIM........................................................................................................................... 2. 1.4. Objectives................................................................................................................. 2. 1.5. Scope of the Research.............................................................................................. 2. 1.6. Alignment of this thesis within the Research Group ................................................... 3. 1.7. Thesis Organization .................................................................................................. 3. Research Fundamentals................................................................................................. 5 2.1. Introduction............................................................................................................... 5. 2.2. Enterprise Integration Engineering (EIE) Reference Framework ................................ 6. 2.2.1 2.3. Zachman Framework........................................................................................ 8. Integration of Technologies ....................................................................................... 9. 2.3.1. Product Life Cycle management (PLM)........................................................... 12. 2.4. Reference Model for Integrated Product, Process and Manufacturing Development 14. 2.5. Action Research (Research Methodology) .............................................................. 15. 3. Literature Review ......................................................................................................... 19. 4. Reference Model to improve the product development process in a company ............... 21 4.1. Enterprise Strategy ................................................................................................. 22. 4.2. Enterprise Modeling ................................................................................................ 24. 4.3. Integration of Technologies ..................................................................................... 25. 4.4. Implementation ....................................................................................................... 29 VI.

(7) 5. Methodology to improve the product development process based on Information. technology implementation .................................................................................................. 30 5.1. 5.1.1. Plan................................................................................................................ 31. 5.1.2. Act.................................................................................................................. 33. 5.1.3. Observe ......................................................................................................... 34. 5.1.4. Reflect............................................................................................................ 34. 5.2. Second Cycle - To-Be model definition.................................................................... 35. 5.2.1. Plan................................................................................................................ 36. 5.2.2. Act.................................................................................................................. 37. 5.2.3. Observe ......................................................................................................... 40. 5.2.4. Reflect............................................................................................................ 40. 5.3. 6. FIRST CYCLE - As-Is Model Understanding ........................................................... 31. Third AR Cycle - To-Be model implementation ........................................................ 41. 5.3.1. Plan................................................................................................................ 42. 5.3.2. Act.................................................................................................................. 42. 5.3.3. Observe ......................................................................................................... 43. 5.3.4. Reflect............................................................................................................ 44. Case of Study............................................................................................................... 45 6.1. FIRST CYCLE - As-Is Model Understanding ........................................................... 45. 6.1.1. PLAN ............................................................................................................. 45. 6.1.2. Act.................................................................................................................. 47. 6.1.3. Observe ......................................................................................................... 47. 6.1.4. Reflect............................................................................................................ 48. 6.2. Second AR Cycle - To-Be model definition.............................................................. 49. VII.

(8) 6.2.1. Plan................................................................................................................ 49. 6.2.2. Act.................................................................................................................. 49. 6.2.3. Observe ......................................................................................................... 50. 6.2.4. Reflect............................................................................................................ 51. 6.3. 7. Third Cycle - To-Be model implementation.............................................................. 51. 6.3.1. Plan................................................................................................................ 51. 6.3.2. Act.................................................................................................................. 52. 6.3.3. Observe ......................................................................................................... 57. 6.3.4. Reflect............................................................................................................ 57. Results......................................................................................................................... 58 7.1. Results of the Reference model and methodology................................................... 58. 7.2. Results of the case study ........................................................................................ 58. 7.3. Benefits and impacts in the product development process....................................... 59. 8. Conclusions.................................................................................................................. 61 8.1. Reference Model and Methodology to improve the Product Development Process .. 61. 8.2. Case Study ............................................................................................................. 61. 8.3. PLM Status............................................................................................................. 62. 9 10. Further Research ......................................................................................................... 63 References ............................................................................................................. 64. VIII.

(9) List of Tables. Table 2-1: Components of the Enterprise Integration Engineering Reference Framework for Product Life Cycle Management. ........................................................................................... 8 Table 2-2 CE and PLM differences ...................................................................................... 13 Table 3-1 Literature reviewed and classified according to the scope of this thesis ................ 20 Table 4-1 Guidelines for strategy definition process (Molina, 2006)...................................... 23 Table 5-1 First Cycle, based on the Zachman Framework.................................................... 35 Table 5-2 Logical Model definition (Molina, 1999)(Alter, 1997) ............................................. 37 Table 5-3 Second Cycle, based on the Zachman Framework............................................... 41 Table 5-4 Third Cycle, based on the Zachman Framework .................................................. 44 Table 6-1 Logical model summary - Plan of the Second AR Cycle ....................................... 49 Table 6-2 Logical model summary - Plan of the third AR Cycle ............................................ 52 Table 6-3 Roles defined in the product development process developed.............................. 53 Table 7-1 Definition of PLM implementation using Logical Model [Rowell,2004] [Wennerstrom, 2004] [Aberdeen Group, Inc, 2002] ...................................................................................... 60. IX.

(10) List of Figures. Figure 2-1 Zachman Framework representation..................................................................... 9 Figure 2-2 Extended enterprise model and related Core process [Molina, 2004] .................. 10 Figure 2-3 e-enterprise concept (Molina, 2003).................................................................... 11 Figure 2-4 PLM system interaction between other e-services tools...................................... 14 Figure 2-5 Key concepts in the Integrated Product, Process, Manufacturing system development (IPPMD) reference Model for Integrated Product, Process and Manufacturing system development............................................................................................................ 15 Figure 2-6 Understand action research (Iversen, et. al., 2002) ............................................. 16 Figure 2-7 Action Research evolution through cycles [Crane and Richardson, 2000]............ 18 Figure 4-1 Relationship between EIE reference model with the reference model proposed to improve the product development process........................................................................... 21 Figure 4-2 Reference model to improve the product development process........................... 22 Figure 4-3 Proposed map for engineering stages of Product Life Cycle (PLC) (Aca, 2003)... 24 Figure 4-4 Example of service architecture in a plant development process ......................... 27 Figure 5-1 EIE-PLM implementation methodology ............................................................... 30 Figure 5-2 First AR Cycle - As-Is Model Understanding ....................................................... 31 Figure 5-3 Second AR Cycle - To-Be model definition.......................................................... 36 Figure 5-4 Reference Model for Integrated Product, Process and Manufacturing system development (Aca, 2003)..................................................................................................... 38 Figure 5-5 Third AR Cycle - To-Be model implementation.................................................... 42 Figure 6-1 AS-IS process for product development. BPMN (Business Process Management Notation) ............................................................................................................................. 47 Figure 6-2 Dynamic Model for product development (Simplified).......................................... 48. X.

(11) Figure 6-3 To-Be process for product development - BPMN (Business Process Management Notation) ............................................................................................................................. 50 Figure 6-4 Product Conceptualization Sub-process - Workflow process developed on SmarTeam .......................................................................................................................... 53 Figure 6-5 Product data/information Management loaded in Smart Team AND Knowledge man..................................................................................................................................... 54 Figure. 6-6. QuickPlace. and. SameTime. collaborative. tools. (http://e-. hub1.mty.itesm.mx:51234/3dcemex) ................................................................................... 55 Figure 6-7 SmarTeam and IBM Collaboration Architecture................................................... 56 Figure 6-8 Final product manufactured ................................................................................ 57. XI.

(12) 1 Introduction. 1.1 Research Problem Product development managers are looking for new ways of doing their business, improving technological, human and organization capabilities. Concepts like Product life cycle management (PLM) have emerged to help companies to be successful, improving the coordination, collaboration and information/knowledge management between all the actors of the product development process. However, implement technologies such as PLM is still a challenge due to a lack of a holistic and systematic methodology. For this reason, product development managers frequently fail in this kind of implementation.. 1.2 Research Justification PLM integration and coordination in a company remain challenging because of its knowledge intensive nature. Schilli B et al (2006) emphasize that introducing new technologies is not just to buy the tools or services. Deep understanding of current business, design of appropriate processes and implementation of supporting IT architecture are essentials for success. Therefore, Garetti M. et al (2005) proposes Experimental Learning techniques and Change Management in order to reach a better PLM implementation recognizing the central role of Virtual Simulation, Business Process Analysis techniques and Process Mapping, remarking on the importance of adopting solutions that are flexible and adaptable due to the constant changes in the enterprises processes. However, this work is characterized for a lack of a reference model that aligns strategy elements and holistic view of the company during the changes developed inside the organization. Thereby, Aca, (2004) propose a reference model for product development in a SME (Small or Medium Companies), which can be configured depending of the different SME requirements. This reference model doesn’t have a methodology to improve the product development process, but present a methodology to configure the reference model in SME. For all these researches, it is clear the need of a systematic methodological and technology supported approach to develop and sustain a successful implementation of the product development system in a company, which is aligned to achieve a complete Enterprise Integration. The methodology used in this work is Action Research. Action Research (AR) is defined as a spiral process that allows action (change, improvement) and research (understanding and 1.

(13) knowledge) to be achieved at the same time (Baskervillea, 1999). Action research, which emphasizes collaboration between researchers and practitioners, has much potential for the information systems (IS) field, because represents a potentially useful qualitative research method (Avison, 2001).. 1.3 AIM This research explores and validates a systematic methodology based on Action Research for the improvement of the product development process.. 1.4 Objectives The objectives of this research are: -. Propose a methodology to improve product development process based on Enterprise Integration Engineering framework, Action Research and PLM approach. -. Validate this methodology in a real case study, by implementing a PLM system using an Action Research (AR) approach as research methodology.. -. Demonstrate how PLM system based on collaboration, coordination, information management and functional (CAX) tools can improve a product development process.. 1.5 Scope of the Research Describes how Enterprise Integration Engineering (EIE) has been used to align the strategic objectives of any company to improve their engineering process using Information Technologies, in particular PLM tools. In this thesis is proposed a methodology that can be applied in the whole product lifecycle, however the validation research work is focused on: customer requirements, product and process engineering design and manufacturing stages. The underlying methodology used to support the implementation process of PLM is Action Research (AR) in order take a systematic approach of planning, implementing, observing and evaluation. The methodology proposed includes standard Action Research concept, however in this methodology is customized in detail each one of the Action Research stages.. 2.

(14) Moreover, in this thesis is to implement a process development process that can impact directly indicators such as time and cost. This thesis is not going to develop a new software application technology. The main idea is to explore a new approach and use current software application technologies developed to validate the research ideas. Also, this methodology can be used in companies that are working in any phase of the product lifecycle, from product concept through recycling. Finally, the modeling concept applied on this thesis is related to businesses processes enterprise integration using enterprise modeling architectures.. 1.6 Alignment of this thesis within the Research Group Research group has been focused in the improvement of the product development process based on technological approaches. Mejia (2003) propose a methodology to implement collaborative engineering environments that foster coordination and collaboration among engineering groups. After that, Aca (2004) propose a reference model to configure the product development process in any SME. However, to really implement improvements in the product development process is necessary to develop a systematic methodology that can help academics and industrials to consider all the project phases, considering different perspectives (Holistic view). In this last issue, this thesis will contribute in the knowledge generation of this research group.. 1.7 Thesis Organization The research presented is organized in six chapters described bellow: •. Chapter 2 – Research fundamentals. Enterprise Integration Engineering, Integration of technologies and Action Research as basis of this thesis.. •. Chapter 3 – Literature review is carried out to know the state of the art of Product Realization Process methodologies.. •. Chapter 4 – Reference Model to improve the product development process in a company.. •. Chapter 5 – EIE-PLM implementation methodology based on Action Research approach is presented.. 3.

(15) •. Chapter 6 – A complete case of study is offered. This chapter show step by step the implementation of methodology proposed in chapter 4.. •. Chapter 7 – Conclusions and further researches.. 4.

(16) 2 Research Fundamentals. 2.1 Introduction In this research, there are four fundamental concepts to support the implementation model developed: 1) Enterprise Integration Engineering (EIE), 2) Reference Model for Integrated. Product,. Process. and. Manufacturing. Development,. 3). technology. integration and 4) Action Research. Enterprise Integration engineering reference framework supports the integration of different entities of the company and value chain. EIE gives the guides to achieve enterprise integration, to finally find technologies that can accomplish it. This integration is based on collaboration and integration among suppliers, customer and enterprise. This thesis is focused on product, process or/and manufacturing development processes, which are particular and complex processes that force the necessity of integration and collaboration between different actor involved. E-engineering service could be a solution for this integration issue. One concrete solution to develop an e-engineering service is the Product Lifecycle Management (PLM) concept, which has been used to foster the integration and traceability in the complete product life cycle. This concept change the perspective to the product development, however implement this concept in the industry is still a challenge. Aca (2003) developed a reference model to improve the Product, Process and Manufacturing system Development (PPMD) process. This reference model is a guideline for SME (Small-Medium Companies) to configure PPMD process; however a systematical and holistic methodology to implement an improvement in PPMD process was not completely developed. In this thesis, Action Research (AR) approach was used to develop a methodology to implement an improvement in the PPMD process. AR is based on learning cycles, where lessons learned from previous iterations (based on experiences) allow the improvement of this implementation methodology. All this concepts will be described in detail in the next sections.. 5.

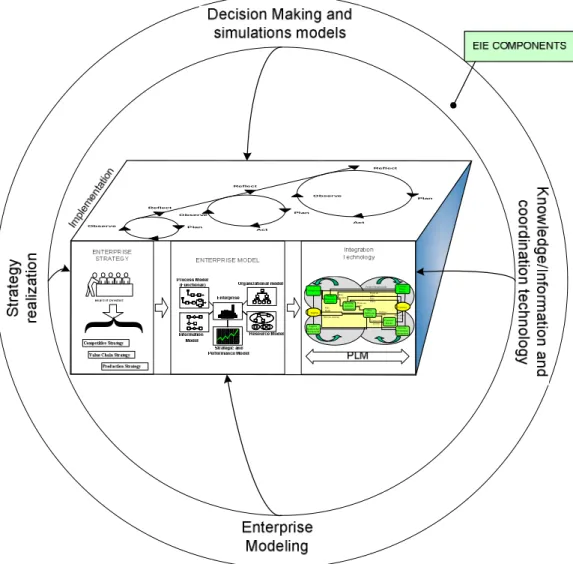

(17) 2.2 Enterprise Integration Engineering (EIE) Reference Framework Enterprise Integration Engineering is the collection of modeling principles, methodologies and tools that support the integration of different enterprise life cycles entities (e.g. enterprise, project, product, processes). The foundation relies on the creation of models of the structure, function and behavior of the different entities. EIE allows a detailed description of all the key elements of an entity (activities, data/information/knowledge, organizational aspects, human and technological resources). In an enterprise model, this description provides the means to connect and communicate all the functional areas of an organization to improve synergy within the enterprise, and to achieve its mission and vision in an effective and efficient manner [Molina, 2005]. For all this issues, EIE reference framework is used to support the PLM implementation methodology. The components of the reference framework are depicted in Table 2-1. Each of the different components provides guidelines, methodologies and tools to engineer business process changes. The components are [Molina, 2005]: - A strategy realization process and performance evaluation systems; they support the definition of three types of strategies in the company, namely: Competitive, Value Chain and Production/Service Strategy. All these strategies are associated with performance measures to evaluate the impact of the strategy pursued in the organization. The competitive strategy should be translated into a set of decisions of how the organizations can deliver value to the customer. Value Chain strategy is about making decisions of how a company will establish an organizational model (external and internal) that will exploit the different possibilities to build an effective and efficient value chain. Production/Service Strategy defines how the company will produce or deliver its products or services - Reference Models for Enterprise Modeling supports the visualization of enterprise knowledge, processes and associated performance measures in order to identify areas of opportunities for improvement. It comprises 8 business processes to describe a generic structure of an ideal intra and inter integrated-extended enterprise: Co-Engineering, Customer Driven Design, Supplier Relationship Management, Customer Relationship Management, New Product Development, Obtaining Customer Commitment, Order Fulfillment/Supply Chain Management, and Customer Service. Exist notation such as EPC (Event-Driven Process Chan), BPMN (Business Process Model Notation) and IDEF-0. - Decision making and simulation models; they support the evaluation of different strategies and implementation of best manufacturing practices and IT (Information Technologies) using different simulation tools such as: dynamic systems and discrete event simulation. Best practices are defined in terms of logic program models to describe its impacts on business performance. System Dynamics simulation: the applied theory of system 6.

(18) dynamics and dynamic systems modeling method come primarily from the work of Jay Forrester [Forrester, 1980]. The models are built based on feedback loops of key performance measures, cause-and-effect models, feedback influences and impacts of effects. Therefore enterprise models of behavior have been developed to demonstrate the effects and impacts of best practices implementation on performance measures [Molina, 2003]. Discrete event simulation: Simulation is the most common method used to evaluate (predict) performance. The reason for this is that a quite complex (and realistic) simulation model can be constructed using actors, attributes, events and statistics accumulation. Business processes simulation can be performed, for example, in order to evaluate resource usage and to predict performance measures among others delivery time and cost, and capacity usage [Molina, 2005]. - Knowledge/Information and coordination technology. Product Life Cycle Management systems allow the product data/information/knowledge management and use of corporate intellectual capital. Product Life Cycle Management (PLM), Business Process Management Systems (BPMS) and Business Process Intelligence (BPI) tools support the execution and analysis of process using business and IT perspectives. BPMS allow process design, execution and tracking based on process engine technology. BPI analysis supports decision making for predicting and optimizing processes. Enterprise Content Management (ECM) integrates the management of structured, semi-structured, and unstructured information, software code embedded in content presentations, and metadata together in solutions for content production, storage, publication, and utilization in organizations [Päivärinta, 2005]. Therefore the utilization of PLM, BPMS and ECM, together with BPI analysis capabilities, can improve the project development process in a company achieving: •. Track the document lifecycle and capture experiences in the process design executed.. •. Allow companies to support business change using a technology driven approach.. •. Project visibility, knowing who, what and when has to deliver each activity.. •. Information and knowledge sharing along all the product lifecycle.. 7.

(19) Table 2-1: Components of the Enterprise Integration Engineering Reference Framework for Product Life Cycle Management.. EIE COMPONENTS Strategy and performance evaluation systems. Reference models for enterprise modelling. Decision-making and simulations models. Knowledge/Information and coordination Technology. ACTIVITIES. TOOLS. - Define Strategies: Competitive, Value Chain and Production/Service - Define Key Performance Indicators: Quality, Volume, Time, Costs, Flexibility, and Environment.. - SWOT - Porters 5s - Scenario Planning - Balance Score Card. - Define enterprise model and core processes - Describe Enterprise Model AS-IS and TO-BE: Functions, Information, Resources, Organization - Determine Key Performance Indicators of the process. - GERAM - IDEF0 - UML - BPMN (Business Process Model Notation) -Event-driven Process Chains (EPC). - Design AS-IS and TO-BE simulation models to evaluate decision making - Define logic models of best business practices and Information Technology. - Evaluate Key performance indicators based on impact of best business practices and IT implementation. -. - Decide type of IT application: functional, coordination, collaboration and Data/knowledge management - Define Data, information, performance indicators and knowledge models - Determine IT architecture - Define IT infrastructure. System dynamics models Discrete event simulation Program logical models Business Process Analysis. - PLM - BPMS (Business Process Management Systems) - BPI (Busines Process Intelligence) - ECM (Enterprise Content Management). 2.2.1 Zachman Framework Other important framework to develop enterprise architectures is the Zachman Framework. Enterprise architecture should be used to lend order to the process of investing resources during the organization’s evolution, and consequently to improve the implementation of new technology to achieve Enterprise Integration. Zachman Framework (Figure 2-1) is organized as 36 cells arranged in a six-by-six matrix. It is a two dimensional scheme, used to organize the detailed representation of the enterprise. The six rows of the framework represent six perspectives, as viewed by the planner, owner, designer, builder, subcontractor and 8.

(20) functioning enterprise. The framework six columns represent different aspects: things, processes, connectivity, people, timing and motivation. At the intersection of each row and column is a cell. Each cell represents a fundamental piece of knowledge relative to the row and column and is known as a primitive [O’Rourke C, 2003].. Figure 2-1 Zachman Framework representation Some concepts of this Framework are going to be used to support the definition of the methodology to improve the product development process. Using this framework, each stage of this methodology can be defined.. 2.3 Integration of Technologies The reference model used for achieve Integration of Technologies it is based on the Extended Enterprise concept [Browne, et. al. 1999; Vernadat, 2002] and the ENAPS Reference Models [Rolstadås 1998] (Figure 2-2). It comprises 8 business processes to describe a generic structure of an ideal intra and inter integrated-extended enterprise. Below is a brief description of the business processes of the Integrated Extended Enterprise Reference Model: CoEngineering, Customer Driven Design, Supplier Relationship Management, Customer Relationship Management, New Product Development, Obtaining Customer Commitment, Order Fulfillment/Supply Chain Management, and Customer Service. 9.

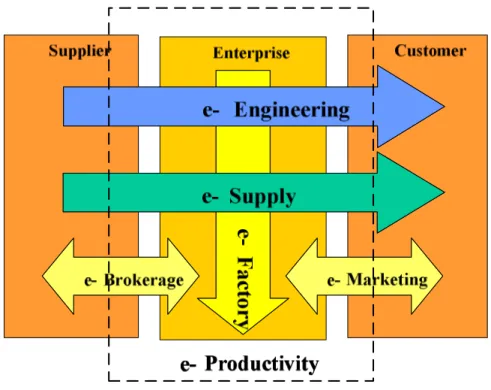

(21) Products Requirements. CoDesign. Co-Engineering Product Realization Process. Places an order Pays Funds. New products. Pays Funds Supplier. Places an Obtaining order customer Order commitment Fulfillment Process. Customer Delivers item. Delivers material. Supplier Relationship Management. Supplier Chain Management. Corrective actions. After sales service. Customer Service Customer Relationship Management. Figure 2-2 Extended enterprise model and related Core process [Molina, 2004]. The reference model can be particularized to any enterprise and its core processes are chosen for modelling and simulation, in order to evaluate process improvement through Business Process Management. Extended Event-Process-Chain (eEPC) diagrams are used to model at different levels of detail the core processes (Figure 2-2). The detail level is defined according to the specification level of the activities included. The first level considers only general process functions; the second level considers specific activities of each function from the first level; and in the third level a deeper specification of activities is achieved for the specific functions from the second level, furthermore, material and information flows can also be included. In order to guarantee an effective global analysis, it is necessary to develop models covering the function and control views [Scheer, 1999] [Molina, 2005]. Moreover, Molina, et.al. (2006) proposes five integrated e-Services (as shown in Figure 2-3) that an enterprise should have to achieve a complete EIE: e-Marketing, e-Brokerage, eEngineering, e-Supply and e-Productivity. The conjunction of these e-Services will improve the competitive position of Latin American SMEs based on the Virtual Organization concept.. 10.

(22) Figure 2-3 e-enterprise concept (Molina, 2003) Brief descriptions of the mentioned e-Services are: e-Marketing to support the development of intelligent Web-portals for promotion of products and services of SMEs; e-Brokerage to underpin the exploitation of business opportunities for the creation of supply chains, integrated networks of micro-enterprises and Virtual Enterprises based on SMEs; eEngineering to establish environments that foster collaboration among engineering groups to support integrated product development; e-Supply integrates services related to e-factory, elogistics for importing/exporting materials and products, supplier and customer relation management; and e-Productivity integrates technologies for the diagnosis, planning, evaluation and monitoring of SMEs. (Molina et.al, 2006) The development and integration of the information and communication technologies needed for the HUBs creation are key issues. Those technologies will enable the creation of Virtual Organizations based on value added industrial networks. The objective of this concept is to create “Integrated e-Services Centres” (HUBs) to allow new business creation. The need of having integrated e-Services emerges from the limitation of individual current electronic services which do not offer a solution to the current technological limitations of the companies. A complete e-enterprise implementation in a company is carried out for the integration of several systems and concepts, as PLM (Product Lifecycle Management), ERP, SCM (Supply Chain Management), CRM (Customer relation management), BPMS (Business Process. 11.

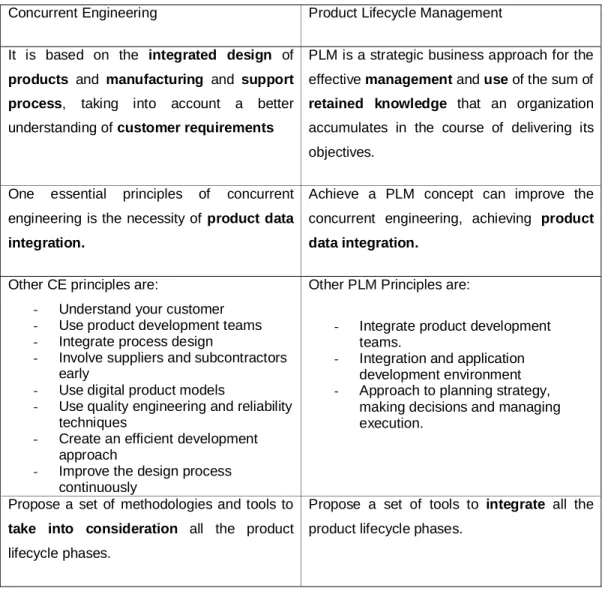

(23) Management Systems) and also by authoring applications (Functional applications), e.g. CAD, CAM, CAE, Office automation [Datamation Limited, 2002]. PLM systems might be considered an important concept for an e-engineering integration in a company that aims to carry out life cycle engineering activities. Research projects at Cranfield University aimed at integrating different enterprise applications through PDM and PLM technologies has been demonstrated that PLM technologies improved the ability of enterprises in effective supply chain management and collaboration concurrently on product development between separate offices and also with the sub-contractors, achieving Enterprise Integration [Gao, 2003]. PLM concept is following defined in detail.. 2.3.1 Product Life Cycle management (PLM) Product Lifecycle Management (PLM) is a strategic business approach that is used to achieve EIE for product development focused on integration of lifecycle information and knowledge supported by computer aided engineering technologies such as: CAD, CAM, CAE, simulation and Knowledge Based Engineering systems. PLM aims to support the management of the product development process through the stages of their life cycles, from concept through recycling. The goal is to maximize the business value for enterprises and their trading. PLM is recognized by world’s leading universities, institutes, and solution vendors as the next big wave in enterprise application software market and a key technology to support the new competitive, value chain and production strategies [Ming, 2005]. The emerging software market is a suite of tools used to plan, manage and execute life cycle activities, which include identifying opportunities, prioritizing R&D efforts, developing products, and supporting production and introduction to the market [Rozwell, 2004]. Defining PLM concept is normal to delimit and explain differences between Concurrent Engineering (CE). CE is a philosophy very similar to PLM, but has some differences, which are explained in the next table (Table 2-2).. 12.

(24) Table 2-2 CE and PLM differences Concurrent Engineering. Product Lifecycle Management. It is based on the integrated design of. PLM is a strategic business approach for the. products and manufacturing and support. effective management and use of the sum of. process,. retained knowledge that an organization. taking. into. account. a. better. understanding of customer requirements. accumulates in the course of delivering its objectives.. One. essential. principles. of. concurrent. Achieve a PLM concept can improve the. engineering is the necessity of product data. concurrent engineering, achieving product. integration.. data integration.. Other CE principles are:. Other PLM Principles are:. Understand your customer Use product development teams Integrate process design Involve suppliers and subcontractors early - Use digital product models - Use quality engineering and reliability techniques - Create an efficient development approach - Improve the design process continuously Propose a set of methodologies and tools to. Propose a set of tools to integrate all the. take into consideration all the product. product lifecycle phases.. -. -. Integrate product development teams. Integration and application development environment Approach to planning strategy, making decisions and managing execution.. lifecycle phases.. In this research a product is anything that might satisfy a want or a need. For example, a product can be an asset, or a complete plant. In this case, concepts like Asset Lifecycle Management tools (ALM) [Peñaranda, 2005] or Enterprise Asset Management (EAM) [Steenstrup, 2005] are used to manage the complete plant life cycle, from process development through disposal. Defining the scope of this research, a technology concept map of some enterprise integration tools are described in the Figure 2-4, according to the literature review developed. This map defines the technological scope of the different tools to integrate the whole company, and can be visualized that PLM system implementation in an enterprise improves the integration in the product development process. Moreover integrate PLM and ERP systems can improve the enterprise integration, connecting the product development process with the company back office.. 13.

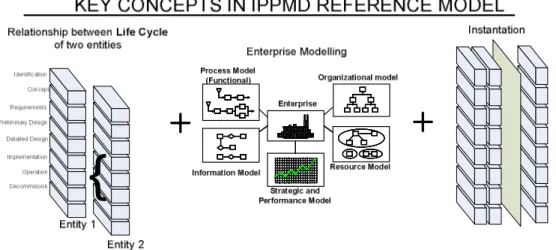

(25) Figure 2-4 PLM system interaction between other e-services tools. 2.4 Reference. Model. for. Integrated. Product,. Process. and. Manufacturing Development Aca, (2003) develop a reference model to develop product, process and manufacturing development framework, which was supported for three fundamental concepts (Figure 2-5): -. Life Cycle. It provides the identification of the life cycle phases for any enterprise entity from entity inception to its decommissioning or end of life. An entity is a description of the possible set of future events or phases. Each entity is defined by seven. life. cycle. phases:. Identification,. Concept,. Requirement,. Design,. Implementation, Operation and Decommission phases. It is important that the lifecycle phases of two entities may be related to each other (Williams, 1998). -. Enterprise Modeling (EM). It supports the specific description of a particular enterprise. This approach will provide construct to describe and model human roles, operational process ad their functional contents as well as the supporting information, office and production technologies (Bernus, 2003). In this approach has defined five different modeling views: Functional (process model), Organizational, information, resource and strategic and performance modeling views.. -. Instantiation. It is the controlled particularization process from generic and partial to particular model. The reference part of the modeling framework itself consists of the generic and partial levels only. The particular level represents the results of the enterprise modeling, which is the model or description of the enterprise entity at the state of the modeling process corresponding to the particular set of life-cycle activities. (Bernus, 2003) 14.

(26) { Figure 2-5 Key concepts in the Integrated Product, Process, Manufacturing system development (IPPMD) reference Model for Integrated Product, Process and Manufacturing system development This reference model is able to construct design methodologies according to the enterprise requirements, selecting activities blocks of this reference model according to the configuration methodology explained in the next section.. 2.5 Action Research (Research Methodology) This research work has been based on using learning cycles, where lessons learned from previous iterations (based on experiences) allowed the implementation in an enterprise. This kind of research methodology concurs with an already situation in the enterprises, which don’t have any experiences in the implementation of Information systems to achieve integration. This methodology is named “Action research”, which consists of a family of research methodologies which pursue action and research outcomes at the same time (See Figure 2-6). Action research is a flexible spiral process which allows action (change, improvement) and research (understanding, knowledge) to be achieved at the same time (Dick, 2002). In most of its forms it does this by: a) Using a cyclic or spiral process which alternates between action and critical reflection and b) In the later cycles, continuously refining methods, data and interpretation in the light of the understanding developed in the earlier cycles.. 15.

(27) Action. Research. Research that does not include design, execution, and assessment of a problemsolving effort. Problem-solving that is not designed, executed, and assessed as an integral part of a research effort Action research, i.e. research that includes and is mainly based on practical problemsolving. Figure 2-6 Understand action research (Iversen, et. al., 2002) Conventional experimental research has developed certain principles to guide its execution. These principles are appropriate for certain types of research, but they can actually inhibit effective change in some cases. Action research has had to develop a different set of principles. It also has some characteristic differences from most other qualitative methods [Dick, 2000]. Action research tends to be: •. Cyclic: Similar steps tend to recur, in a similar sequence;. •. Participative: The clients and informants are involved as partners, or at least active participants, in the research process;. •. Qualitative: It deals more often with language than with numbers; and. •. Reflective: Critical reflection upon the process and outcomes are important parts of each cycle.. In most of its forms it is also participative (among other reasons, change is usually easier to achieve when those affected by the change are involved) and qualitative. It is thus an emergent process which takes shape as understanding increases; it is an iterative process which converges towards a better understanding of what happens. The understanding allows more informed change and at the same time is informed by that change. People affected by the change are usually involved in the action research. This allows the understanding to be widely shared and the change to be pursued with commitment. Action research, which emphasizes collaboration between researchers and practitioners, has much potential for the information systems (IS) field, because represents a potentially useful qualitative research method (Avison, 2001).. 16.

(28) Action research commonly proceeds like this: The researcher plans the first or next step and is then carried out. Researchers meet to recollect and critique their experience. In the light of this, they decide what to do for the next step (what information do they need or what outcome to pursue, and what method to use). In short, action research alternates between action and critical reflection. The reflection consists first of analyzing what has already happened in previous steps, and then of planning what next step to take. Action research, which emphasizes collaboration between researchers and practitioners, has much potential for the information systems (IS) field, because represents a potentially useful qualitative research method (Avison, 2001). Action research aims to contribute both to the practical concerns of people in an immediate problematic situation and to the goals of social science by joint collaboration within a mutually acceptable framework. In most of its forms it is also participative (among other reasons, change is usually easier to achieve when those affected by the change are involved) and qualitative. It is thus an emergent process which takes shape as understanding increases; it is an iterative process which converges towards a better understanding of what happens. (Dick, 2002) It is true that action research and some forms of practice are in some ways similar. Both are often directed towards the achievement of change.. Both are qualitative and often. participative. Both tend to be flexible and cyclic. In both instances, there is a desire to base planned changes in the situation on understanding, and to derive that understanding from evidence. With the exception of well-practiced tasks there is a natural rhythm to the way most of humans behave. They do something, and then they check if it worked as expected. If it did not, is analyzed what happened and what they might do differently. If necessary the process is repeated (act -> review -> act -> review and so on) Most writers on the topic state or assume that action research is cyclic, or at least spiral in structure. One crucial step in each cycle consists of critical reflection. The researcher and others involved first recollect and then critique what has already happened. The increased understanding which emerges from the critical reflection is then put to good use in designing the later steps. The reflection leads on to the next stage of planning. The "planning" isn't a separate and prior step; it is embedded in the action and reflection. As change is intended to result, effective action research depends upon the agreement and commitment of those affected by it. This is usually generated by involving them directly in the research process. In many instances, researchers try to involve them as equal partners. The diagram on Figure 2-7 shows the way that Action Research evolves through cycles of planning, action, observation and reflection. The rising base line represents the goal of. 17.

(29) continuous improvement. Successive cycles become larger and represent the way that the process may change over time.. Reflect. Reflect Observe. Plan. Reflect Plan. Observe. Act Observe. Plan. Act. Act. Figure 2-7 Action Research evolution through cycles [Crane and Richardson, 2000]. The methodology proposed in the EIE reference Framework is based on Action Research. The methodology consists in AR spirals, however the plan, act, observe and reflection phases are depicted in detail. This structure gives to the methodology the possibility to be evaluated in each cycle and consequently to be improved. In the next section will be explained the framework of this methodology, using concepts explained in this section.. 18.

(30) 3 Literature Review. In the Table 3-1 is presented the literature reviewed and is classified according to: −. Core Perspectives: EIE proposes four perspectives to achieve a complete enterprise modeling: functional, organizational structure, resources (Technological and human) and Information view. These different perspectives will be explained in detail in the next section (4.2).. −. Enterprise Strategy: This is an important issue to accomplish a successful implementation. An implementation without consider enterprise strategy should be unsuccessful, implementing changes with any impact within the company.. −. Reference Model/Framework/Standards: To develop a methodology, is important to define a reference model, framework or standards that will be the basis.. −. Implementation Methodology: It is important to evaluate if there are researches that are developed methodologies to improve the product development process.. The literature and current practice indicate the necessity of a methodology that take into consideration different perspectives, achieving a successful implementation. From the previous evaluation, important issues are: -. Most of the researches are focused in the technological and information view.. -. Enterprise strategy is not taken into consideration in most of this works reviewed.. -. It is clear the necessity of a methodology that can involve all this perspectives and enterprise strategy, and finally that can be based on a reference model.. 19.

(31) Huang, 2006. X. Huang and Gu, 2006 He, 2006. X. X. X. X. X. X X. X. X. X. Schilli B et al (2006). X. X. X. Zhang and Qiu, 2006. X. X. X. Yung, (2006). X. X. X. Chen, 2005. X. X X. X. Ming, 2005. X X. X. X X. X. X. X. X. IEEE Std. 1490, 2004. X. X. X. X. X. X. X. Cutting-Decelle, 2003. X. X. Gao, 2003. X. X. X. X X. Mostefai, 2004. Datamation Limited, 2002 Halpern, 2002. X. X. X. X. X. X. Subrahmanian, 2005. Chen, 2002. Reference model/ Standards/ Framework. X. Nina, 2006. Messaadia, 2005. Enterprise Strategy. X. X X. Garetti M. et al (2005). improvement. X. Information management. Balakrishna, 2006. Human Resources. Resources implementation. PRINCIPAL AUTHOR. Resources (Technological). Organizational improvement. Process improvement. Methodology or reference model Focus on:. Implementation Methodology. Table 3-1 Literature reviewed and classified according to the scope of this thesis. X. X. X. X. X. X. X. X. X. X. X. 20.

(32) 4 Reference. Model. to. improve. the. product. development process in a company. According to the literature reviewed, a successful improvement in the product development process considers four important issues: Enterprise Strategy, Enterprise Modeling, Integration of technologies and implementation (Figure 4-1Table 5-1). In Figure 4-1 is described the relationship between reference model proposed and EIE reference model components. In this figure are related each component with each reference model component using arrows. For example, Action research (Spirals) is used to evaluate and analyze changes in the organization using decision making and simulations models.. Reflect. Reflect. Observe. Plan. Reflect Plan. Observe. Act Observe. Plan. Act. Products Requirements C o-Engineering Product Realization Process. New prod ucts. {. Pays Fu nds. Obtaining Places an o rder cu stomer commitment. Supplier Delivers material. Places an order Pays Fund s. C ustomer. Ord er Fulfillmen t Process. Delivers item. Corrective actio ns Supplier Relationship Man ag ement. C ustomer Dr iven Design. After sales service. C ustomer Serv ice Custo mer Relation ship Management. Figure 4-1 Relationship between EIE reference model with the reference model proposed to improve the product development process 21.

(33) The reference model proposed in this work is described more clearly in the figure 4-2. In the next sections, each key concept in this reference model will be explained.. Reflect. Reflect Observe. Plan. Reflect Plan. Observe. Act Observe. Plan. Act. Products Requirements Co-Engineering Product Realization Process. New products. Pays Funds. Places an Obtaining order customer commitment. Supplier Delivers material. Places an order Pays Funds. Customer Driven Design. Customer. Order Fulfillment Process. Delivers item. Corrective actions Supplier Relationship Management. After sales service. Customer Service Customer Relationship Management. Figure 4-2 Reference model to improve the product development process. 4.1 Enterprise Strategy The strategic goals are defined to accomplish the vision and mission defined for the company. To implement an improvement in the product development process, this implementation must to be aligned with one o several strategic objectives defined for the company. It is important to clarify this aspect, because the company has to establish priorities to evaluate and select the best projects that can achieve the highest impact in the strategic goals defined. Balance Scorecard could be used to help the definition of these strategies. Analysis tools and guidelines are provided to define three propositions to achieve competitive advantage: product innovation, operational excellence and customer focus [Hope and Hope 1997]. In Table 4-1 depicts different process of strategic decision making, using different analyses for strategic decisions and performance measures to evaluate their impacts.. 22.

(34) Table 4-1 Guidelines for strategy definition process (Molina, 2006) Business Strategic elements. Key Performance Measures. Competitive Strategy. % sales of new products. - Product innovation. ROI, operational cost. - Operational excellence. Customer loyalty. - Customer focus Value Chain Strategy. Quality. - Vertical integration. Volume. - Strategic Business Units. Time. - Horizontal integration. Costs. - Collaboration (Vertical network or horizontal. Flexibility. network).. Environment. Production Strategy. Quality. - MTS (Make to Stock). Volume. - MTO (Make to order). Time. - ATO (Assembly to order). Costs. - CTO (Configure to order). Flexibility. - BTO (Build to order). Reconfigurability. - ETO (Engineer to order).. Environment. The competitive strategy should be translated into a set of decisions of how the organizations can deliver value to the customer. The company can decide to be competitive in product innovation, operational excellence and customer focus. Value Chain strategy is about making decisions of how a company will establish an organizational model (external and internal) that will exploit the different possibilities to build an effective and efficient value chain. Different decisions can be conceived in value chain strategy: Vertical Integration, Structuring into Strategic Business Units, Horizontal Integration and Establishment of a Collaborative Organizational Structure. (Molina, et-al, 2005) Production strategy defines how the company will produce or deliver its products or services. The production/services strategy is based on the following factors: product description, characterization of customers and suppliers, and process definition. All these factors are defined by order-qualification and order-winning criteria [Hill 1989]. The criteria are: price, volume, quality, lead-time, delivery speed and reliability, flexibility, product innovation and design, and life cycle status.. Based on all these performance measures the following. production strategies may be defined (Molina and Medina 2003):. 23.

(35) •. Production Strategy: Make to Stock (MTS), Make to Order (MTO), Assemble to Order (ATO), Configure to Order (CTO), Build to Order (BTO) and Engineer to Order (ETO).. •. Service Strategy: Services on Catalogues (SoC), Configuration of Services (CoS) and Design of Services (DoS). The impact of these strategies in a company should be able to be measured using a performance evaluation system. Performance measures are defined in the following dimensions: Quality, Time, Cost, Volume, Flexibility and Environment.. 4.2 Enterprise Modeling The engineering of an enterprise is a highly sophisticated, multidisciplinary management, design and implementation exercise during which various forms of description and models of the target enterprise will be created (IFIP-IFAC task force, 2003).. For these reason. Enterprise Models (EMs) represents the enterprise operations form various modeling viewpoint, which reduce the complexity to develop enterprises models. Thereby the objective is to describe the operational process (entities, stages and activities) as an integrated model, but to be presented to the user in different sub-sets of an integrated model. In the Figure 4-3 are defined the different stages for each process, and each stage (e.g. Product Idea) must have defined the function, organization, information, resource and performance modeling views. These views are necessary to describe a complete enterprise model (Sheer (1998) and Bernus (2003)). Figure 4-3 Proposed map for engineering stages of Product Life Cycle (PLC) (Aca, 2003). 24.

(36) •. Function view represents activity functionality and behavior (i.e. events, activities and processes). It is important to model the core processes and activities that support the product development in the SME.. •. Information view allows the detailed description of data, information and knowledge required in the integrated product development. The data/information/knowledge structure must be considered, in order to define the starting specifications for a PDM (Product Data Management) or ECM (Enterprise Content Management) (Päivärinta, and Munkvold, 2005) structuring. This make possible to know how the product and manufacturing information are structured.. •. Resources view represents the tools, methodologies, human and infrastructure that are needed to develop an activity. The different tools can be classified in 1) Functional: function oriented systems that support engineers in specific tasks, for example CAD, CAM, CAE, KBES, and Rapid Prototyping tools; 2) Coordination: coordination systems to support sequencing of activities and flow of information., for example workflow and project management; 3) Collaboration: collaboration systems to foster cooperation among engineer, i.e. CSCW - Computer Supported Cooperative Working; and 4) Information Management: product and manufacturing information management systems, knowledge based management systems (Mejía, et.al., 2004).. •. Organization view is the identification of the human resources and how they are organized and defined within the organizational view. It must establish the relations among the areas/departments/partners involved in a simultaneous engineering (concurrent engineering) environment.. The organization structure is important, in. order to identify the key participants in the engineering activities, not only for execution, but also for reviewing, supervising and monitoring. •. Performance view is gathered all the indicators that support the PPMD process. These indicators measure the process efficiency and also can measure strategic objectives of the company. Define these indicators from the company strategies, could develop projects according to the mission and vision of the SME.. 4.3 Integration of Technologies This last key concept is based on the Enterprise Application Integration (EAI). Basically, integration means bringing together of two or more organizations or enterprises. One of the challenges facing modern organizations is giving all their workers complete, transparent and real-time access to information. Many of the legacy applications still in use today were developed using arcane and proprietary technologies, thus creating information silos across departmental lines within organizations. These systems did not enable seamless movement of information from one application to the other. EAI, as a discipline, aims to alleviate many of these problems, as well as create new paradigms for truly lean proactive organizations. For 25.

(37) this reason, collaboration tools that link applications and teams are under research. Authors such as Mejía, et.al, (2006) propose an e-collaboration classification, which is defined by the concept of integrate internal and inter-organizational processes supported by internet-based tools (Martina H. Gerst, 2003). This classification can help us to implement the technology thinking in the integration issue. •. Functional Tools: These tools support specific execution of a task or a group of tasks allowing the fulfillment of specific objectives within different stages of product development. These kinds of applications are frequently automated or semiautomated engineering methodologies or techniques. Usually a well defined sequential and logical activity performed to accomplish precise objectives, is able to be automated. In addition, such activity can be executed with a computer to support decision making. Two types of functional tools have been identified: Functional Tools based on Information (as QFD and FMEA applications), and Functional Tools based on models (as CAD, CAM, CAE and CAX).. •. Tools for Information and knowledge management. In the last decades the continuous introduction of new technologies to improve information/knowledge storage, sharing, processing, and analysis have changed the way engineers execute tasks; from manual processes to computer tools based on Information and Knowledge Management. The efforts in structuring information to support the product development process have been focused on: o. Product modeling: The product model has to represent all the necessary information used through the life cycle of a product such as customer’s requirements,. design,. fabrication,. production,. assembly,. packaging,. distribution and collecting/recycle/re-use to support decision making (Krause et al. 1993) o. Manufacturing modeling: The manufacturing model must represent the technological and production capabilities. The information entities which define the manufacturing information modeling are the resources, process, and strategies. The manufacturing and process resource describe the technological capabilities. Other issues are new strategies which represent the real capability of the enterprise. The manufacturing strategies represent the information that is specific for each organization. This information helps to identify resources and certain processes which aid in determining the strategy for the proposed enterprise. (Molina and Bell, 1999). Achieving the link between this two information structures will improve the product and manufacturing knowledge. Knowledge Based Engineering Systems can achieve this integration, improving for example the Design for Manufacturing. 26.

(38) Other important concepts in this field, is the use of ontology and data mining. Ontology is increasingly seen as a key technology for enabling semantics-driven knowledge processing. Communities establish ontology, or shared conceptual models, to provide a framework for sharing a precise meaning of symbols exchanged during communication (Maedche, 2003). Ontology provides structured, formal, and unambiguous sets of terms for describing certain domain vocabularies. Ontology supports communication by providing a shared vocabulary with well-defined meanings, thus avoiding ambiguities and misunderstandings (Huang, 2006). Data mining is the process of searching and analyzing data in order to find implicit, but potentially useful, information. It involves selecting, exploring and modeling large amounts of data to uncover previously unknown patterns, and ultimately comprehensible information, from large databases. For example, all this concepts could be used to develop service architecture such as the described in Figure 4-4. This service architecture is based on four kinds of data: 1) Ontologies, 2) Data Miner, 3) Repository of modular components and 4) Product development documentation. These four concepts can be linked and should improve the information management in a product the development process (Chapman, 2001), (Maedche, 2003), (Shaw, 2001), (Huang, 2006).. Figure 4-4 Example of service architecture in a plant development process. 27.

(39) •. Coordination Tools. Engineering Design is a process, wherein a requirement or idea is transformed in the necessary information in order to develop a new product or system. Successful management of this process is summarized in the effective handling of three issues (Hales, 1993): 1) Activities of the design team (such as: task planning, report revision/elaboration, cost estimation or information recovery), 2) Outputs from the design team (is the analysis of measurable variables, being the performance measurements of the design team activities) and 3) Influences on the design team (such as: markets, customers, management changes, motivation and technological developments). These tools can be classified in modeling, executing and controlling tools. o. Modeling tools are based in notations. The most known notations are the EPC (by ARIS) and Business Process Modeling Notation BPMN (by Business Process Management Initiative). From this, can connect all the views defined in an EIE (Function, Information, Resources and organization).. o. Executing systems as Business Process Management Systems, Enterprise Resource Planning and Workflows that support the execution of the process. Many IT companies have developed robust solutions. For example, Many PDM systems execute a workflow to track the product lifecycle and this workflow can be integrated with the ERP system (Depending on the ERP and PDM solution), achieving a complete enterprise integration.. o. Controlling Tools. In this classification, Business Intelligence (BI) tools are used to monitor and control the process executed. BI is about having the right information available to the right decision makers at the right time to help organizations make better decisions faster. (Abukari, 2003). •. Communication Tools. Communication tools enable the interaction between project members involved in the different stages of the product lifecycle (design, processes and manufacturing systems development). Through the use of these tools, it is possible to support collaboration environments that facilitate remote activities execution.. According to this reference model proposed, e-enterprise tools must to be implemented after of a strategy analysis and enterprise modeling development. In the next section, it will be proposed a methodology to achieve integration in the product development process.. 28.

(40) 4.4 Implementation This final issue is the implementation. It is based on Action Research (AR) approach, which is very useful to evaluate and reflect the implementation. Enterprise strategy, enterprise model and integration of technologies are used to develop this implementation. Action Research consists in Plan, Act, Observe and Reflect stages, and each stage is divided in activities related with this reference model proposed. In the next chapter this methodology will be explained in detail.. 29.

(41) 5 Methodology to improve the product development process. based. on. Information. technology. implementation. This methodology is a guide to improve the product design process in a company. For this reason this methodology use a three Action Research cycles to increase the knowledge in the current business model and can suggest improvements in the AS-IS process (Figure 5-1). Finishing the third cycle, the Information systems technology in the company has been implemented. EIE is the integration of several systems (e.g. ERP, SCM, CRM, BPMS, and PLM) and is recommended to implement these systems separately; therefore the action research cycle has to continue with the complete EIE implementation and improvement of the enterprise integration. However, this research is focused on the improvement of the product development process in a company; thereby the PLM concept implementation presents more attention. The different cycles of this methodology are following described.. PLAN. ACT. REFLECT. PLAN. REFLECT. OBSERVE ACT. PLAN. REFLECT ACT. REFLECT. OBSERVE REFLECT. REFLECT. OBSERVE. Figure 5-1 EIE-PLM implementation methodology. 30.

(42) 5.1 FIRST CYCLE - As-Is Model Understanding In this first cycle is developed a diagnostic and an identification of the enterprise strategy. The objectives of this first cycle (Figure 5-2) are: 1) Model the process AS-IS and, 2) Suggest new improvements on the AS-IS model. These objectives are achieved using interviews with the process owners and managers, which know the actual product design development process in the company and company strategies in that order. The different stages of this first cycle are following described.. Identify business objectives and strategies AsAs-Is Understanding. Figure 5-2 First AR Cycle - As-Is Model Understanding. 5.1.1 Plan - Define work team, responsibilities, activities and resources. The project plan is made, which is accordant to the scope, the resources and the work team defined. It is suggested the integration of process owners and IT analyst in the AS-IS analysis and TO-BE model design. The activities of this project plan are based on the activities of this methodology. - Analyze the vision, mission and strategic objectives in the company. This activity is a fundamental step to align the product development process improvements with the company interests. External consultants will improve the definition or analysis, because they can develop an analysis without any interests or influences. Recommended tools as, Balance Score Card is a useful methodology to define the strategic objectives in the company. Nevertheless, some suggestion to develop or evaluate a mission and vision are:. 31.

(43) Define the vision and mission, and finally the strategic goals are important issues to align product development changes with company strategy. A Mission must present the following characteristics: •. Express the purpose of the company. •. Company mission is a long-term definition. •. Mission must emphasize the distinguishing aspects of the organization. •. Mission must identify the approach of their operations in terms of service and market. Company Vision must present the following characteristics: •. The wished future profile for the organization. •. Challenges and declaration in relation to the excellence. •. Elements that motivate the employees. •. Elements of the employee’s participation and the clients. •. Preparation elements for the future. •. Elements that it is remembered and it provides a guide. - Define the project scope, benefits and impacts. EIE implementation benefits and impacts must to be clear and defined, and must to be aligned with company strategy. A product development process improvement is our objective, and in complex process establishes a scope of these improvements is an important task to be developed. This strategy can show benefits and impacts in a comparatively short time, and then could be easily accepted to the top management for a complete implementation. Although, this first cycle is going to improve a part of the product development process, the implementation has to be developed as complete product development solution, specifically, EAI has to be considered. - Analyze the business strategic elements and Key Performances Indicators (KPI). To set the context for the implementation of PLM systems, there is a need to clarify the strategy of the company.. There are three business strategic elements proposed: Competitive strategy,. Value chain and Productive strategy (these elements are defined in the literature review section). After this strategy selection, KPIs are selected to monitor the impacts on the strategy defined. PLM could support different business process, of particular interest are: co-design, co-engineering and product development. Some indicators in PLM implementations could be capital savings, cost reductions, increase collaboration between stakeholders, improved organization efficiency, and reduction of project execution. Other indicators are defined by IT analyst, such as how long it takes to a process to be executed, what resources were used to execute that process, among others [Peñaranda, 2005]. - Identify the key business process with highest impact and drivers of change.. It is important. to define which process and specific stages of the whole product development process in the. 32.

Figure

![Figure 2-2 Extended enterprise model and related Core process [Molina, 2004]](https://thumb-us.123doks.com/thumbv2/123dok_es/3216989.582449/21.918.168.736.101.458/figure-extended-enterprise-model-related-core-process-molina.webp)

Documento similar

This work consists of a formal definition to classify all the different exoskeletons by doing a catego- rization of all the general sub-sections that the exoskeletons have, done

The latter is a modeling language intended for model-driven development of component- based software systems and for the early evaluation of non-functional properties such as

L´ opez-Grao, J., Merseguer, J., Campos, J.: From UML activity diagrams to stochastic Petri nets: Application to software performance engineering. G´ omez Mart´ınez, E., Merseguer,

AHP-FMEA-DA proposed method is an integration of AHP, FMEA, and DA methodologies, where the AHP will help to improve the way to assess the NPD process risks, then the FMEA

Among the expected results is the development of a conceptual model specialized in the container terminal and the agent- based model approach of event management system to

In the context of the sequencing of the human and mouse genomes, databases such as Ensembl and the UCSC Genome Browser were created as online repositories in order to

For example, we can check whether a relation or the whole transformation is applicable in the forward direction (i.e., whether there is a source model enabling a relation), forward

reference architecture for the development of teleoperated service robots control units (ACROSET), and also an application in the context of the EFTCoR project that show the

![Figure 2-7 Action Research evolution through cycles [Crane and Richardson, 2000]](https://thumb-us.123doks.com/thumbv2/123dok_es/3216989.582449/29.918.228.708.194.503/figure-action-research-evolution-cycles-crane-richardson.webp)