SLIDING WEAR CHARACTERIZATION OF CEMENTED CARBIDES FOR HIGH PERFORMANCE CUTTING TOOLS

Texto completo

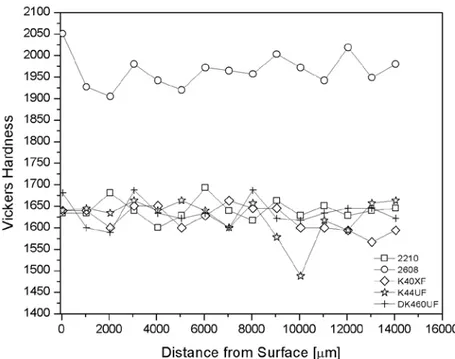

Figure

Documento similar

In this respect, a comparison with The Shadow of the Glen is very useful, since the text finished by Synge in 1904 can be considered a complex development of the opposition

In the previous sections we have shown how astronomical alignments and solar hierophanies – with a common interest in the solstices − were substantiated in the

The two ILs containing the bis(trifluoromethanesulfonyl)amide anion presented lower coefficient of friction compared to that having the dimethyl phosphate anion. The

Figure 4 shows changes in the friction coefficient of the substrate and the coatings, according to the sliding distance, where the steady state is clearly seen. During this state

Wear test for NiCoCrAlY specimens has shown smaller weight losses and lower friction coefficient under high temperature, meanwhile CoNiCrAlY coating shows a unexpected ware rate

In Figure 2 we show the results of the functionalized graphene as reinforcements for UHMWPE-based composites. After running-in period, friction coefficient for the

THE EFFECT OF AIR–LUBRICATION ON SHIP FRICTION RESISTANCE 32 scale ship to predict the distribution of the air bubble void fraction on the hull surface, which

No obstante, como esta enfermedad afecta a cada persona de manera diferente, no todas las opciones de cuidado y tratamiento pueden ser apropiadas para cada individuo.. La forma