UNIVERSIDAD DE VALLADOLID

ESCUELA DE INGENIERIAS INDUSTRIALES

MÁSTER EN INGENIERÍA QUÍMICA

Recrystallization kinetics of API/polymer systems

Autor: Rodríguez del Egido, Miguel Guillermo

Responsable Intercambio UVa:

Mato Chaín, Rafael B.

Technische Universität Dortmund

TFM REALIZADO EN PROGRAMA DE INTERCAMBIO

TÍTULO: Recrystallization kinetics of API/polymer systems ALUMNO: Miguel Guillermo Rodríguez del Egido

FECHA: 18/04/2017

Palabras clave: Recristalización, compuesto farmacéutico, nifedipina, dispersión sólida, Avrami.

Resumen: El compuesto nifedipina es prácticamente insoluble en agua y consecuentemente no se alcanza todo el potencial de sus propiedades. Para superar estas limitaciones, se utiliza la técnica de dispersión sólida. Sin embargo, formulaciones en estado amorfo obtenidas tienden a recristalizar.

Se estudiaron diferentes factores influyentes en la recristalización. De acuerdo a la composición de la formulación, cuanta menor concentración del compuesto farmacéutico, mayor es el tiempo para cristalizar. Respecto a la humedad relativa (RH), existe una gran diferencia entre los valores iniciales y finales de agua absorbida en los experimentos con las RH implementadas. Respecto a la temperatura, cuanto menor es la temperatura, mayor es tiempo necesario para alcanzar el equilibrio. También se llevaron a cabo experimentos cambiando el polímero y el modo de preparar la formulación.

Para caracterizar las muestras se utilizaron Powder X-Ray Diffraction (PXRD), Differential Scanning Calorimetry (DSC) y espectrofotómetro.

Technische Universität Dortmund

Fakultät Bio- und Chemieingenieurwesen

Lehrstuhl für Thermodynamik

Recrystallization kinetics of API/polymer systems

Master-Thesis

Miguel Guillermo Rodríguez del Egido

Matriculation Number: 197306

Dortmund, 18.04.2017

Supervisor:

First Examiner:

M. Sc. Christian Lübbert

Prof. Dr. Gabriele Sadowski

i

Declaration of authorship

I affirm that this thesis is completely my work and that any material from other sources is

marked in the text to the best of my knowledge. I also assure that I have not submitted any

part of this work for a degree at any other institution.

Dortmund 18.04.2017

ii

Abstract

The goal of this master project is to study the crystallization of nifedipine from water content

absorbed by analyzing different influencing: active pharmaceutical ingredients (API) weight

fraction, temperature, relative humidity (RH), polymer and the method to prepare the

formulation.

The drug is practically insoluble in water, consequently its properties do not reach its full

potential. To overcome these limitations, the solid dispersion method was the solution. It was

originally used to improve the dissolution properties and the bioavailability of poorly water

soluble drugs by dispersing them into water soluble carriers.

The amorphous solid dispersions were prepared by spray drying method with a Büchi Mini

Spray Dryer B-290.

When preparing the formulation, the same steps were always followed in order to have the

same thermodynamic history for all the samples. When preparing the amorphous solid

dispersion, acetone was used as solvent. The inlet temperature was 60 °C and the outlet

temperature was in a range of 35-40 °C.

After spray drying or melting method, the results show that the solid dispersions were totally

amorphous. In order to characterize the solid state of the sample, powder X-ray diffraction

(PXDR) and differential scanning calorimetry (DSC) were used.

The Avrami equation has proved its validity to model the behavior followed by the

crystallization. The parameters obtained agree with the results achieved from the suspension

balance experiments. It has been shown that the assumption of n parameter equal to 4, which

is crystal growth in 3 dimensions, is correct.

According to the API weight fraction, the lower API concentration the sample contains, the

longer it takes to crystallize. It could be the case that with that weight fraction does not reach

the recommended dose, in that case it would have to reach a compromise between the weight

fraction and the improved properties achieved and the recommended dose. On the other side,

iii

In terms of relative humidity, a huge difference occurs among the several relative humidities

that have been implemented. These differences translate into variations in the time required to

reach the equilibrium and crystallize and the initial and final water content.

Regarding to the temperature, the lower temperature under the sample is at, the longer it takes

to crystallize. Thereby, in order to avoid crystallization, it is necessary to operate under a

minimum temperature.

In respect of the method to prepare the formulation, differences in time to crystallize emerged.

Thus, the time needed for the melting method, which is normally used in industry, is less than

the time required for spray drying method. In this manner, in order to avoid crystallization, it

might be considered a way to use and optimize the spray drying method on a large scale.

Respecting the polymer used in the formulation, it was noticed that PVAC retarded the time

to crystallize so that it better fulfills the purpose of avoiding crystallization than Resomer

R203s. In further investigations, more polymers will have to be studied in order to find the

iv

List of symbols

Symbol Interpretation

wAPI Weight fraction of API

wNIF Weight fraction of Nifedipine

Tin Inlet temperature

Tout Outlet temperature

List of abbreviations

Abbreviation Interpretation

API Active Pharmaceutical Ingredient

NIF Nifedipine

FDA Food and Drug Administration

RH Relative humidity

PXRD Powder X-Ray Diffraction

DSC Differential Scanning Calorimetry

UV-Vis Ultra Violet – Visible

A Absorbance

VLE Vapor Liquid Equilibrium

SVLE Solid Vapor Liquid Equilibrium

PVAC Polyvinyl acetate of molecular weight 90.000

g/mol

PVAC350 Polyvinyl acetate of molecular weight

350.000 g/mol

v

List of figures

Figure 1. Scheme of spray drying method [6] ...5

Figure 2 Hot melt extrusion process [7] ...7

Figure 3. PXDR pattern of an amorphous sample (wNIF 70%)...8

Figure 4. PXDR pattern of a recrystallized sample (wNIF 80%, PVAC350, 40°C, 75%RH) obtained after the suspension balance experiment ...8

Figure 5. DSC thermogram of NIF/PVAC (wNIF 70%, PVAC, 40°C, 75%RH) ...9

Figure 6. Behavior of solubility against temperature and API weight fraction [10] ... 10

Figure 7. Behavior of solubility and present phases against temperature and weight fraction [10] .... 11

Figure 8. Evolution of water weight fraction: (a) initial curve for amorphous formulation at temperature I, (b) at temperature II, and (c) at temperature III [10] ... Figure 9. Behavior of NIF solubility [10] ... 12

Figure 10. Behavior of water content and phases during crystallization for a wNIF 70% [10] ... 13

Figure 11. Interaction of the three components of the system ... 16

Figure 12. Interaction of the forces involved in the EoS... 17

Figure 13. Characteristic sigmoidal curve followed by crystallization [16] ... 20

Figure 14. Graph where the slope is the n parameter [17] ... 21

Figure 15. Molecular structure of NIF ... 22

Figure 16. Molecular structure of NIF polymorphs [23] ... 23

Figure 17. Behavior of the two polymorphs on heating and cooling [23] ... 24

Figure 18. Theoretical NIF pattern by PXRD ... 24

Figure 19. Büchi Mini Spray Dryer B-290 experimental installation ... 26

Figure 20. Suspension balance experimental installation ... 27

Figure 21. Rigaku Miniflex 600 equipment ... 29

Figure 22. TA Instruments DSC Q-2000 equipment ... 30

Figure 23. Eppendorf BioSpectrometer equipment ... 31

Figure 24. Fitting of the experimental and VLE NIF curves [25] ... 33

Figure 25. Sorption diagram for sample wNIF 80%, 40°C, 60°RH ... 34

Figure 26. Sorption diagram for sample wNIF 80%, 40°C, 75°RH ... 35

Figure 27. Sorption diagram for sample wNIF 80%, 40°C, 90°RH ... 35

Figure 28. Sorption diagram for sample wNIF 80%, 35°C, 75°RH ... 36

Figure 29. Sorption diagram for sample wNIF 80%, 30°C, 75°RH ... 36

Figure 30. Overlap of the two independent water sorption measurements obtained for wNIF=0.80 at 40 °C, 75% RH to check the reproducibility of the experiments ... 37

Figure 31. Evolution of water content along the weight fraction ... 38

Figure 32. Evolution of water content along RH... 39

Figure 33. Evolution of water content along temperature for wNIF 90% and 75%RH... 40

Figure 34. Evolution of water content along temperature for wNIF 80% and 75%RH... 40

Figure 35. Evolution of water content along temperature for wNIF 70% and 75%RH... 41

Figure 36. Evolution of water content along polymer for wNIF 80%, 40°C and 75%RH ... 42

Figure 37. Evolution of water content along the method to prepare the formulation for wNIF 80%, 40°C and 75%RH ... 43

vi

Figure 39. Evolution of concentration of crystals, water and API for reference sample (wNIF 80%,

40°C, 75%RH) ... 45

Figure 40. PXRD pattern of amorphous state of sample wNIF 80% ... 46

Figure 41. PXDR pattern of crystalline state of sample wNIF 80%, 40ºC and 75%RH ... 46

Figure 42. Coupling of the experimental curve and Avrami theoretical curve ... 49

Figure 43. K coefficient behavior with API weight fraction ... 50

Figure 44. K coefficient behavior with relative humidity... 51

Figure 45. K coefficient behavior as function of temperature... 53

Figure 46. Concentration of components in the liquid phase for sample wNIF 0.90, 40°C, 75%RH ... 58

Figure 47. Evolution of concentration of crystals, water and API for sample wNIF 0.90, 40°C, 75%RH ... 58

Figure 48. Concentration of components in the liquid phase for sample wNIF 0.70, 40°C, 75%RH ... 58

Figure 49. Evolution of concentration of crystals, water and API for sample wNIF 0.70, 40°C, 75%RH ... 59

Figure 50. Concentration of components in the liquid phase for sample wNIF 0.85, 40°C, 75%RH ... 59

Figure 51. Evolution of concentration of crystals, water and API for sample wNIF 0.85, 40°C, 75%RH ... 59

Figure 52. Concentration of components in the liquid phase for sample wNIF 0.75, 40°C, 75%RH ... 60

Figure 53. Evolution of concentration of crystals, water and API for sample wNIF 0.75, 40°C, 75%RH ... 60

Figure 54. Concentration of components in the liquid phase for sample wNIF 0.80, 40°C, 75%RH by melting-cooling ... 60

Figure 55. Evolution of concentration of crystals, water and API for sample wNIF 0.80, 40°C, 75%RH by melting-cooling ... 61

Figure 56. Concentration of components in the liquid phase for sample wNIF 0.80, 40°C, 90%RH ... 61

Figure 57. Evolution of concentration of crystals, water and API for sample wNIF 0.80, 40°C, 90%RH ... 61

Figure 58. Concentration of components in the liquid phase for sample wNIF 0.80, 40°C, 60%RH ... 62

Figure 59. Evolution of concentration of crystals, water and API for sample wNIF 0.80, 40°C, 60%RH ... 62

Figure 60. Concentration of components in the liquid phase for sample wNIF 0.90, 30°C, 75%RH ... 62

Figure 61. Evolution of concentration of crystals, water and API for sample wNIF 0.90, 30°C, 75%RH ... 63

Figure 62. Concentration of components in the liquid phase for sample wNIF 0.90, 35°C, 75%RH ... 63

Figure 63. Evolution of concentration of crystals, water and API for sample wNIF 0.90, 35°C, 75%RH ... 63

Figure 64. Concentration of components in the liquid phase for sample wNIF 0.80, 35°C, 75%RH ... 64

Figure 65. Evolution of concentration of crystals, water and API for sample wNIF 0.80, 35°C, 75%RH ... 64

Figure 66. Concentration of components in the liquid phase for sample wNIF 0.80, 30°C, 75%RH ... 64

Figure 67. Evolution of concentration of crystals, water and API for sample wNIF 0.80, 30°C, 75%RH ... 65

Figure 68. Concentration of components in the liquid phase for sample wNIF 0.70, 35°C, 75%RH ... 65

vii

Figure 70. Concentration of components in the liquid phase for sample wNIF 0.90 in Resomer R203s,

40°C, 75%RH ... 66

Figure 71. Evolution of concentration of crystals, water and API for sample wNIF 0.90 in Resomer R203s, 40°C, 75%RH ... 66

Figure 72. Concentration of components in the liquid phase for sample wNIF 0.80 in Resomer R203s, 40°C, 75%RH ... 66

Figure 73. Evolution of concentration of crystals, water and API for sample wNIF 0.80 in Resomer R203s, 40°C, 75%RH ... 67

Figure 74. Concentration of components in the liquid phase for sample wNIF 0.70 in Resomer R203s, 40°C, 75%RH ... 67

Figure 75. Evolution of concentration of crystals, water and API for sample wNIF 0.70 in Resomer R203s, 40°C, 75%RH ... 67

Figure 76. Calibration curve of NIF at 276 nm in acetonitrile ... 71

List of tables

Table 1. Thermal properties of the different polymorphs [24] ... 23Table 2. Conditions of the experiments in suspension balance ... 28

Table 3. PC-SAFT API parameter ... 32

Table 4. Binary interaction parameters ... 33

Table 5. Degree of crystallinity of the samples by mass balances ... 44

Table 6. Melting enthalpies obtained by DSC measurements ... 47

Table 7. Results from UV-Vis measurements ... 48

Table 8. K coefficients with API weight fraction variation ... 50

Table 9. K coefficients with relative humidity variation ... 51

Table 10. K coefficients with temperature variation for wNIF 90% ... 52

Table 11. K coefficients with temperature variation for wNIF 80% ... 52

Table 12. K coefficients with temperature variation for wNIF 70% ... 52

Table 13. K coefficients with polymer variation ... 53

Table 14. K coefficients with method of preparation variation ... 54

Table 15. Measurements in the spray drying process ... 57

Table 16. DSC method ... 69

Table 17. Data about samples and their DSC measurements ... 68

viii

Contents

Declaration of authorship ...i

Abstract ... ii

List of symbols ... iv

List of abbreviations ... iv

List of figures ... v

List of tables ... vii

1. Aim of the project ...1

2. Theory ...3

2.1 Stabilization of APIs in polymeric matrices (solid dispersions) ...3

2.1.1 Methods of preparation ...4

2.1.2 Solid state characterization ...7

2.2 Phase behavior of API/polymer-formulations ...9

2.3 Influence of humidity on the phase behavior ... 13

2.4 Estimation of crystallinity via mass balances and water sorption ... 14

2.5 Calculation of activity coefficients via PC-SAFT ... 16

2.6 JMAK equation ... 19

3. Materials and experimental methods ... 22

3.1 Materials ... 22

3.2 Experimental methods ... 25

3.2.1 Preparation of formulations via spray drying ... 25

3.2.2 Suspension balance experiments ... 26

3.2.3 Verification of crystallinity via PXRD and DSC ... 28

3.2.5 UV-Vis measurements ... 30

4. Results and discussion... 32

4.1 Modeling the phase behavior of API/polymer-formulations ... 32

4.2 Predicting the influence of humidity on the phase behavior ... 34

4.3 Results of suspension balance experiments ... 36

4.3.1 Influence of wNIF... 37

4.3.2 Influence of RH ... 38

4.3.3 Influence of Temperature ... 39

4.3.4 Influence of polymer type ... 41

4.3.5 Influence of the method to prepare the formulation ... 42

ix

4.5 Results of UV-Vis measurements ... 48

4.6 Determination of Avrami-coefficients... 49

4.6.1 Influence of wNIF ... 50

4.6.2 Influence of RH ... 51

4.6.3 Influence of Temperature ... 52

4.6.4 Influence of polymer type ... 53

4.6.5 Influence of the method to prepare the formulation ... 54

5. Conclusion ... 55

1

1. Aim of the project

Nifedipine (NIF) is a calcium channel blocker, widely used clinically as a coronary

vasodilator. Pharmaceutical preparations are available as capsules, tablets, and solutions, and

the drug is usually administered orally or intravenously. The drug is practically insoluble in

water, and is reported to be highly light sensitive

The current way of administration implicates a number of weaknesses. In fact, NIF is usually

provided as solution using liquid oral drug preparation or by cutting a soft gelatin capsule and

by squeezing out the fluid content beneath the tongue [1]. This mode of administration can

lead to dosage and assimilation variability. The administration of NIF solid dispersions (SD),

by using a suitable polymeric carrier, comes out an interesting modus operandi in order to

progress into a better dose precision, residence time and patient compliance.

The SD method was initially used to ameliorate the dissolution properties and the

bioavailability of poorly water soluble drugs by dispersing them into water soluble carriers.

Dissolution deceleration through SD method using water insoluble polymer for the

development of controlled release dosage forms has become a field of interest in latest years

[2].

The progress of controlled release SD has a great advantage for avoiding the risk of a sudden

release of drug; as the structure of the solid dispersion allow a homogeneous dispersion of the

drug molecules [2].

Amorphous formulations have attracted considerable attention in the pharmaceutical field. As

the molecular structures of drug candidates become increasingly complex, solubility often

becomes a limiting factor in dissolution and oral absorption. The use of the amorphous form

is a promising strategy to battle these limitations due to its higher free energy and, therefore,

higher apparent solubility than its crystalline equivalent. However, such amorphous

formulations are metastable and tend to convert spontaneously to the crystalline state.

When crystallization occurs during processing, or during the shelf-life of the pharmaceutical

product, bioavailability and product efficacy may be adversely affected. Therefore, an

understanding of the crystallization kinetics from the amorphous state and the prediction of

2

Long term stability tests are imposed by Food and Drug Administration (FDA) at defined

Temperature and relative humidity (RH) conditions with which their long term stability is

verified and the appropriate polymer and concentration for the formulations are acquired.

The aim of this master thesis is to study the crystallization velocity of NIF formulations from

the water content absorbed analyzing different influencing factors: active pharmaceutical

ingredient (API) weight fraction, temperature, RH, polymer and the method to prepare the

formulation. It brings into focus the characterization of the ternary system

(API-polymer-water).

Finally, the predicted crystallization profiles are calculated and compared with the

3

2. Theory

An API is the chemical compound of any formulation which is pharmaceutically active. Some

formulations, such as integration treatment, have multiple active ingredients to treat different

diseases.

All drugs are made up of two core elements: the API, which is the central ingredient, and the

excipient, the substance inside the drug that helps deliver the medication to the desired place

within the organism. Excipients are inactive substances, such as polymers, and not chemically

active.

According to the U.S. Food and Drug Administration, an API is defined as:

“Any substance or mixture of substances intended to be used in the manufacture of a drug

product and that, when used in the production of a drug, becomes an active ingredient in the

drug product. Such substances are intended to furnish pharmacological activity or other direct

effect in the diagnosis, cure, mitigation, treatment or prevention of disease or to affect the

structure and function of the body.” [3].

2.1 Stabilization of APIs in polymeric matrices (solid dispersions)

Amorphous formulations have attracted considerable interest in the pharmaceutical field as a

way of improving bioavailability [2,4]. As the molecular structures of drug candidates

become increasingly complex, solubility often becomes a limiting factor in dissolution and

oral absorption.

The crystalline state is thermodynamically the most stable solid state, and is characterized by

both lower solubility and higher chemical stability [30].

When crystallization occurs during processing, or during the useful life of the pharmaceutical

product, bioavailability and product efficacy may be adversely affected.

The process of crystallization is known to be composed of two major steps: nucleation and

crystal growth, and the rates are generally governed by molecular mobility affecting the

diffusion rate of molecules and thermodynamic factors such as the Gibbs free energy and

4

Preparation of poorly water-soluble APIs into amorphous forms improves their solubility.

However, amorphous solids are often physically metastable because of their high energy state,

and crystallization during storage presents a problem.

A promising strategy to improve the dissolution limited bioavailability would be to use the

amorphous state and take advantage of the higher solubility of this high free energy state. On

the other hand, because amorphous drugs are in a higher free energy state than a

corresponding crystalline state, re-crystallization is thermodynamically favored.

The phase behavior of solid dispersions can be extremely complicated, whereby the API can

potentially be present in its crystalline state (which may involve one or more polymorphic

forms) or as a fully or partially amorphous form. For amorphous solid dispersions, one

important aspect of the phase behavior is the miscibility of the amorphous phases of the drug

and the polymeric carrier.

2.1.1 Methods of preparation

There are numerous methods to prepare a solid dispersion. Below it is proceed to describe

some of them [2]:

Spray drying

Spray drying is a unit operation capable of transforming solutions or suspensions into a solid

product. The spray drying technique comprises four basic steps: atomization of the liquid,

mixing of the liquid with the drying gas, evaporation of the liquid and separation of the dried

particles from the gas [2].

The liquid solution is transferred from the beaker to the nozzle entrance by a pump system. In

case of solid dispersion preparation, the used solvents are mostly organics.

As the slurry enters the tower, it is atomized into fine droplets. Partly because of the high

surface tension of water and partly because of the hydrophobic/hydrophilic interactions

5

Several types of atomization devices are available, depending on the type of energy that is

involved: centrifugal energy, pressure energy, kinetic energy and vibrations.

All spray dryers use some type of atomizer or spray nozzle to disperse the liquid or slurry into

a controlled drop size spray. The most common of these are rotary disk and single-fluid high

pressure swirl nozzles.

The small size of the drops (averaging 100 micrometers in diameter) results in a relatively

large surface area which dries quickly. As the water dries, the carrier forms a hardened shell

around the load. The final product is removed from the gas phase in a cyclone and collected in

a cyclone at the end of the process [5]

A general scheme for a spray drying equipment is depicted in the following Figure 1:

Figure 1. Scheme of spray drying method [6]

Melting method

The melting method involves melting of a physical mixture of drug and carrier to the liquid

6

one of the advantages is that it is a solvent free method. However, the API and the excipient

should be miscible and mixed well [4].

Melting solvent method

The melting solvent technique is a combination of the solvent evaporation method and

melting method [2].

It is carried out by the dissolution of the drug in an appropriate solvent and the mixture of this

solution with the molten carrier followed by cooling for solidification. The advantage of this

method is that it needs inferior temperatures with lesser risk of decomposition of thermolabile

drugs than other methods.

Solvent evaporation method

This technique consists of dissolving the drug and excipient simultaneously in a common

solvent, followed by the withdrawal of the solvent by evaporation.

Many drugs and carriers cannot be utilized for others methods, such as melting method, due to

their high melting points, then they can be used for solvent evaporation method [2].

Hot melt extrusion

The advantages of this technique include lower temperature than other methods and shorter

residence time of the drug carrier mixture. The physical mixture of drug and excipient is

moved into the heated chamber of extruder at a controlled rate.

Since the physical mixture is carried through heated screws, it is melted, which allows

homogeneous mixing. In the last step of the process the melt is shaped in the required form

7

The following Figure 2 shows a general outline of the process:

Figure 2 Hot melt extrusion process [7]

Supercritical antisolvent method

It is said a single fluid phase is supercritical when it is above its critical pressure and

temperature. Carbon dioxide is the most used supercritical fluid.

Several terms are used according to the technique by which supercritical fluid and solution are

mixed: (1) precipitation from supercritical solutions by fast expansion of supercritical

solution, (2) precipitation from saturated solution using supercritical fluid as an antisolvent,

(3) precipitation from gas saturated solutions [2].

2.1.2 Solid state characterization

Owing to the importance of the nature of solid dispersions, either crystalline or amorphous

state, it is needed to verify which state has been achieved both at the beginning and at the end

of each experiment.

For this reason, several techniques have been used. These are Powder X-Ray Diffraction

(PXRD) and Differential Scanning Calorimetry (DSC) since they are the most generally used

techniques to define the solid state. Spectrophotometer has been used in order to measure the

8

PXDR is a technique using X-Ray to illustrate the crystalline state of materials. The scattering

of X-rays from atoms produce a diffraction pattern that contains information about the atomic

structure. Amorphous materials do not produce any significant peak in diffraction pattern,

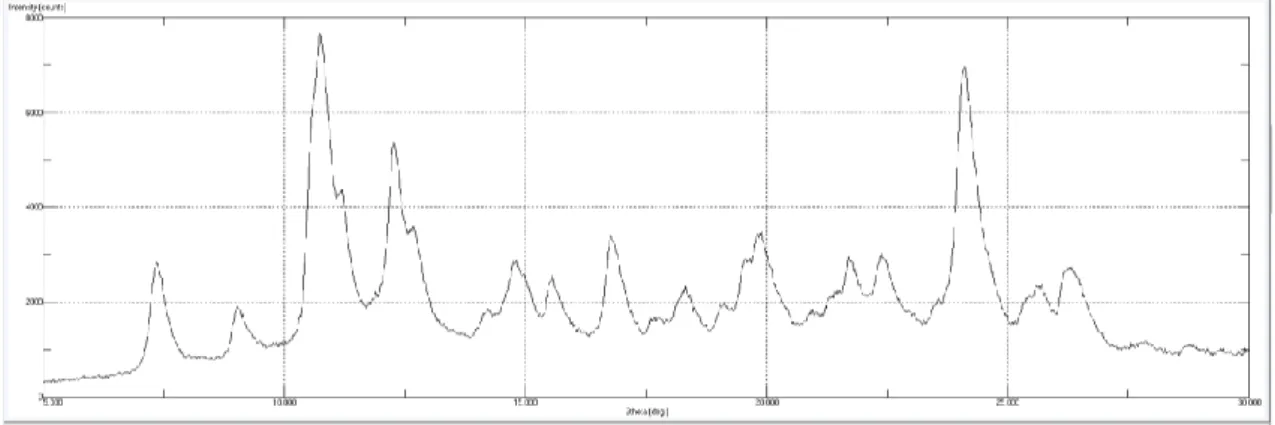

while crystalline materials are completely the opposite as it can be seen in Figures 3 and 4 [8].

Figure 3. PXDR pattern of an amorphous sample (wNIF 70%)

Figure 4. PXDR pattern of a recrystallized sample (wNIF 80%, PVAC350, 40°C, 75%RH) obtained

after the suspension balance experiment

DSC is an analytical technique in which the difference in heat flow between a sample and an

inert reference is measured as a function of time and temperature as both are subjected to a

controlled environment of time and temperature [9].

DSC analyses give information about melting temperature and enthalpy by the study of

9

Figure 5. DSC thermogram of NIF/PVAC (wNIF 70%, PVAC, 40°C, 75%RH)

A UV-VIS Spectrophotometer has been used to measure the absorbance at a particular

wavelenght in order to verify the composition of both components at the end of experiment.

2.2 Phase behavior of API/polymer-formulations

In this section, it will be discussed the phase behavior of API-polymer formulations. The

phase behavior of the system depends on the conditions in which the work is being done,

thereby different cases can be found.

The knowledge of the phase behavior is of great interest for practical application. When

recrystallization or an amorphous phase separation of the API / polymer system is observed,

the end of the shelf life of the formulation is achieved.

165.95°C 158.58°C 49.92J/g -0.8 -0.6 -0.4 -0.2 0.0 0.2 0.4 H e a t F lo w ( W /g )

-50 0 50 100 150 200 250

Temperature (°C) Sample: PVAc+NIF_wAPI70%_40_75%RH2

Size: 7.4000 mg

Method: Miguel DSC

File: \\...\PVAC+NIF_WAPI70%2.001 Operator: MR

Run Date: 31-Oct-2016 12:31

Instrument: DSC Q2000 V24.11 Build 124

10

The stability of the mixture is determined by the solubility. The maximum quantity of API

that can be dissolved in the polymer without crystallization is the API solubility in the

polymer and thus depends on the phase behavior of the resulting API/polymer formulation.

Figure 6. Behavior of solubility against temperature and API weight fraction [10]

As it can be seen in Figure 6, solubility separates two contrasting areas. Below the solubility

concentration the API-polymer formulation is stable and at API concentrations higher than the

solubility, the system tends to crystallize as it is supersaturated and unstable.

On the other hand, it also affects the miscibility gap between the compounds. Therefore it can

be distinguished several zones as it can be seen in Figure 7. The green area (upper area)

corresponds to the stable zone in which the system is in amorphous state. In the purple sector

(upper inner area of the miscibility curve), it is found two liquid phases corresponding to

polymer and water. In the dark orange sector (lower area) within the miscibility gap, it is

found two liquid phases as in the previous sector and recrystallization may occur as well.

Finally in the light orange area there is recrystallization as the concentration is greater than the

11

Figure 7. Behavior of solubility and present phases against temperature and weight fraction [10]

If a high API concentration is present, the solubility of the API in the polymer/water mixture

is exceeded, the API recrystallizes and a vapor-solid-liquid equilibrium ensues.

It is assumed that the vapor phase still consists exclusively of water. In the liquid phase

amorphous API and polymer as well as sorbed water are present. The solid phase consists of

pure crystalline API. The recrystallization of the API reduces the API concentration in the

12

The evolution of the water weight fraction from the amorphous to crystalline state can be

followed in the next Figure 8.

In the next Figure 9, it can be observed the evolution of solubility in this specific case of a

Nifedipine-PVAC sample in conditions of 40°C and 75% RH.

Figure 9. Behavior of NIF solubility [10]

Figure 8. Evolution of water weight fraction: (a) initial curve for amorphous formulation at

13 2.3 Influence of humidity on the phase behavior

In this chapter, it will be discussed the effect of humidity in the polymer-API system as it is

being studied the crystallization by the water absorbed. Amorphous solid dispersions are

prone to absorb water which drives to crystallization of API. Both the API solubility and

water sorption depends on type of API and polymer on the formulation, as well as the

temperature and the RH [10].

The water sorption of the formulations depends on the physical state of them. Phase

transformations can be observed as function of time.

Figure 10. Behavior of water content and phases during crystallization for a wNIF 70% [10]

As it can be seen in the previous Figure 10, the maximum value of water weight fraction

corresponds to amorphous nature and as time goes on the sample begins to crystallize until

reaching the minimum possible water value [11].

As the relative humidity of the amorphous system was increased, a decrease in the glass

transition temperature was noticed indicating an increase in molecular mobility which leads to

a faster crystallization [12]

Therefore, on the one hand, water absorbed from the vapor phase induces API crystallization;

and on the other hand, the crystallinity of the API/polymer system determines the quantity of

14 2.4 Estimation of crystallinity via mass balances and water sorption

In order to estimate the crystallinity of the sample from the water sorption, obtained from the

suspension balance experiments, it is necessary to make use of mass balances and

Vapor-Liquid-Equilibrium (VLE) and Solid-Vapor-Vapor-Liquid-Equilibrium (SVLE).

Regarding to the mass balances, it was required to implement a global mass balance to the

whole system and a mass balance to every substance taking into account the two existing

phases: solid and liquid.

One assumption taken is that the water is absorbed only by the amorphous liquid phase. The

solid phase consists exclusively of crystalline API, polymer and water are insoluble in the API

crystal.

Furthermore, the mass of the amorphous polymer in the liquid phase of the water-free system

is equal to the mass of polymer in the water-loaded system.

The mass of API in the saturated liquid phase and in the crystalline solid corresponds to the

mass of the API in the water-free system.

Global mass balance:

(1)

In this expression, mean the total liquid and solid phase respectively.

Water mass balance:

15

In which the total water mass is the sum of water mass in the liquid phase and the water mass

in the solid phase. This last one is equal to zero, , due to it was assumed that the solid

phase, that is the crystals, is completely composed by NIF.

On the other hand, the liquid water mass depends on the absorbed water weight fraction and

the formed crystal percentage per total mass .

(3)

Polymer mass balance:

(4)

Where the polymer total mass is equal to the sum of polymer liquid phase mass and the

polymer solid phase mass. As it was said before, as it was assumed that the solid phase is

completely composed by API, then the polymer mass in the solid phase is zero.

(5)

And the polymer liquid phase weight fraction depends on the API and H2O weight fraction.

(6)

API mass balance:

16

In this expression, the API total mass is equal to the addition of API liquid phase mass and

API solid phase mass. As it was assumed that the solid phase is completely composed by

nifedipine, then .

On the other side, the liquid phase weight fraction depends on the absorbed water and the API

water free-liquid phase weight fraction ( ), which was obtained from the VLE.

(8)

2.5 Calculation of activity coefficients via PC-SAFT

The Perturbed-Chain Statistical Associating Fluid Theory (PC-SAFT) is an equation of state

designed for modeling mixtures of all types of substances: gases, solvents and polymers.

PC SAFT is satisfactory for the calculation of phase equilibrium and thermodynamic

properties of pure components and mixtures. It is found to be more precise comparing to other

equation of state (EoS) for correlation of experimental data and more predictive when applied

to mixtures. It is very reliable for extrapolations over the regions where parameters were

adjusted. Comparison to the original SAFT equation of state reveals significant improvement

for both, mixtures of small components and polymer solutions [13].

17

A huge advance in modeling phase behavior of polymer systems has been made during the

last years with use of EoS. In many such theories chain-like molecules are modeled as chains

of freely-jointed spherical segments.

The PC-SAFT equation of state is based on perturbation theory with the hard chain as

reference fluid. The perturbation contributions account for dispersive attractions as well as

association interactions and the reduced residual Helmholtz energy [13].

In accordance with this model, molecules are determined by three pure component

parameters:

- Attraction parameter ε

- Segment number m

- Segment diameter σ

In spite of its clarity, this molecular model considers the vital characteristics of real

molecules. Those characteristics are:

- Repulsive interactions

- Non-spherical shape of molecules (chain formation)

- Attractive interactions (dispersion)

18

The hard chain contribution represents the repulsions between the molecules. The attractions

of molecules are considered by dispersive interactions and strong hydrogen bonding which

exists between the associating molecules.

Therefore, the free residual energy ares is calculated [14]:

(9)

Despite considerable work on further developments, one of the most successful models

remains the original SAFT equation of state. However, in the dispersion term of the original

SAFT model, the chain-like structure of polymer compounds is not taken into account.

In the Perturbed-Chain SAFT equation of state, the dispersive forces are accounted for

applying a perturbation theory of second order (Barker and Henderson), using an expression

for the radial pair distribution function of a hard-chain reference fluid [13]

For utilization of the PC-SAFT equation of state to real substances, the integral in the

dispersion term is replaced by a power series in density, where the coefficients show a simple

dependence on segment number.

To characterize an associating substance, the number of association sites as well as their type

has to be assigned according to the molecular structure. Five pure component parameters for

associating substances have to be identified:

Segment number:

19

Segment diameter:

(11)

Dispersion energy parameter:

(12)

Association energy:

(13)

Association volume:

(14)

2.6 JMAK equation

In order to represent a model for the kinetics of crystallization, it has been used the Avrami

equation. It describes the transformation of one phase from another by the growth of nuclei

that are randomly formed in the primary phase.

The Avrami equation is also known as Johnson Mehl Avrami Kolmogorov (JMAK) equation

[15].

The crystallization is usually observed to follow a characteristic sigmoidal curve in which it

can be differentiated three zones. At the beginning, the crystallization rate is slow as it is the

time required for a significant number of nuclei of the new phase to form. The intermediate

20

again since most of the compound has been crystallize and there is less material to convert,

the particles already existing start to touch each other.

Figure 13. Characteristic sigmoidal curve followed by crystallization [16]

It has been assumed important simplifications to follow Avrami equation [17]:

- Nucleation occurs randomly and homogeneously over the entire untransformed

portion of the material.

- Growth rate does not depend on the degree of transformation.

- Growth happens at the same velocity in all directions, the growth is isotropic.

Thus, the number of nuclei is based on the volume, the nucleation rate and the time interval in

which it is measured.

(15)

Developing this initial equation, the final equation is reached, the usual form of Avrami

21

(16)

Where

It can also be written as:

(17)

This equation allows the estimation of the transformation constants, K and n, as it can be seen

in the next Figure 14.

Figure 14. Graph where the slope is the n parameter [17]

K and n are transformation parameters. The n parameter depends on the dimension of the

22

3. Materials and experimental methods

3.1 Materials

Nifedipine was purchased from Tokyo Chemical Industry CO., LTD. (Tokyo, Japan) with a

purity of >98.0%

Poly(vinyl acetate) (PVAC) of a molecular weight of 90.000 g/mol was acquired from

Polysciences Inc. (Warrington, PA, USA). Poly(vinyl acetate) (PVAC) of a molecular weight

of 350.000 g/mol was purchased from Scientific Polymer Products Inc. (Ontario, NY, USA).

Resomer® R203 S was acquired from Evonik Industries (Darmstadt, Germany).

Acetone with a purity of 99.9%, was purchased from VWR International GmbH (Darmstadt,

Germany) was used to prepare the formulations of API and the polymers for spray drying.

NIF is a yellow crystalline substance, practically insoluble in water but soluble in ethanol. It

has a molecular weight of 346.3 g/mol and a melting point of 173 °C.

NIF is an antianginal drug belonging to a class of pharmacological agents, the calcium

channel blockers. NIF is used to treat hypertension (high blood pressure) and angina (chest

pain). It works by relaxing the muscles of your heart and blood vessels. [19].

Nifedipine has the following structural formula [20]:

23

Polymorphism, that is the occurrence of chemical compounds characterized by the same

structural formula but different crystal forms, is a phenomenon of fundamental importance in

organic chemistry as different molecular structure may cause considerable variations in the

physical and chemical properties of the compound such as the melting temperature or

enthalpy. In the case of nifedipine, three polymorphs have been described: modification III,

modification II (or β) and modification I (or α). Only β and α polymorphs are metastable and

stable [21,22].

Figure 16. Molecular structure of NIF polymorphs [23]

Table 1. Thermal properties of the different polymorphs [24]

Properties α NIF β NIF

Melting temperature (°C) 169-173 162-164

Melting enthalpy (J/g) 104 71

In order to differentiate the two polymorphs, it was also found the different behavior on

heating and cooling. It can be appreciated, in Figure 17, the contract between the shape of the

24

Figure 17. Behavior of the two polymorphs on heating and cooling [23]

According to the X-Ray diffraction, Figure 18 is the pattern of the β polymorph [23], which

will be used later to distinguish them as well.

25 3.2 Experimental methods

In the experimental procedure, different stages can be distinguished:

3.2.1 Preparation of formulations via spray drying

The exact quantity of polymer and API contained in each sample was weighted by a balance

from Sartorius (Göttingen, Germany) following the selected rates of 70%, 75%, 80%, 85%,

90% NIF. Every sample was 1g.

Next, 100 mL of acetone were added to the mixture to keep a rate of 1/100. Before

performing the spray dying, it was needed to stir the solution in order to have it completely

dissolved and homogeneous.

In order to perform the solid dispersion preparation, a Mini Spray Dryer B-290 from Büchi

has been used.

Firstly, a nitrogen flow was fed into the equipment, so the oxygen inside decreases, to set up

inert conditions in the spray dryer. Regarding to aspiration, it was established at a value of

90% of the total capacity of the system.

Once the system was under inert conditions, the heater was started; the selected inlet

temperature was 60°C, with which 35-40 °C was reached as outlet temperature. After the

selected inlet temperature was achieved, the equipment was drained with pure acetone for 5

minutes to get the drying conditions. The pump rate was set at a point of 30% of its capacity.

Afterwards, the spray dryer method started when the pure solvent was switched to the

previously prepared solution. At the end of the process, it was switched back to acetone to

clean nozzle and tubes.

Finally, the powder resulting from the process was collected with a plastic spoon and stored in

26

Figure 19. Büchi Mini Spray Dryer B-290 experimental installation

3.2.2 Suspension balance experiments

The suspension balance is the equipment where the water sorption and recrystallization have

taken place. Once the solid dispersion was ready from spray drying, the sample was brought

here immediately.

Firstly, the solid dispersion was placed in a glass pan which went to the interior of the

chamber. Here, the working conditions were vacuum with respect to pressure and the selected

temperature during 2 hours, the time needed to reach equilibrium, in order to dry the sample.

Once the equilibrium is achieved, the operating conditions were changed. The pressure was

established according to the percentage of required relative humidity and vapor pressure of

27

The experiments concluded when the equilibrium was achieved.

Figure 20. Suspension balance experimental installation

28

Table 2. Conditions of the experiments in suspension balance

API weight fraction (%) Polymer Temperature (°C) RH (%)

90 PVAC 40 75

80 PVAC 40 75

70 PVAC 40 75

90 PVAC 30 75

80 PVAC 35 75

90 PVAC 35 75

70 PVAC 35 75

80 PVAC 40 90

80 PVAC 40 60

80 PVAC 40 75

80 PVAC350 40 75

80 PVAC350 40 75

90 PVAC350 40 75

80 Resomer 203s 40 75

70 Resomer 203s 40 75

90 Resomer 203s 40 75

85 PVAC 40 75

75 PVAC 40 75

80 PVAC (Melting) 40 75

70 PVAC (Melting) 40 75

80 PVAC 40 75

80 PVAC 30 75

80 PVAC350 40 75

90 PVAC 40 75

3.2.3 Verification of crystallinity via PXRD and DSC

The PXDR measurements have been carried out by Miniflex 600 from Rigaku (Tokyo, Japan)

in order to determine if the solid dispersions were amorphous right after the spray drying and

29

The quantity of the sample to be analyzed was around 5 mg and was kept on a silica area.

Figure 21. Rigaku Miniflex 600 equipment

The DSC measurements have been performed by DSC Q2000 device manufactured by TA

Instruments (New Castle, DE, USA) in order to determine thermal characteristics such as

degree of crystallinity and melting temperature and enthalpy. These were studied by using TA

Universal Analysis software.

For these measurements, an amount of 4-10 mg was weighted and placed in a standard pan.

Some of the adjustments, such as heating rate, were taken from the equipment manual. The

30

Figure 22. TA Instruments DSC Q-2000 equipment

3.2.5 UV-Vis measurements

In order to verify the final nifedipine concentration of every sample, absorbance was

evaluated. The precise concentration in solution was measured by using a BioSpectrometer®

from Eppendorf (Hamburg, Germany).

The spectrophotometer was set at a specific wavelength. The absorbance of the nifedipine was

measured at 276 nm. The solvent used was acetonitrile. The samples were measured three

31

32

4. Results and discussion

In this section, all the results of the experiments performed are presented. Results from

suspension balance, DSC, PXDR and spectrophotometer are shown.

Besides, the influence of every single factor in the solid dispersion is discussed.

4.1 Modeling the phase behavior of API/polymer-formulations

The modeling of the VLEs was determined in this thesis using the PC-SAFT state

equilibrium. In order to model the system was necessary the pure substance parameters and

binary interaction parameters. The pure substance parameters used for the modeling are listed

in Table 3. In addition to the required pure substance parameters, the binary interaction

parameters kij for NIF-water, NIF-PVAC, NIF- Resomer R203s and the polymers with water

were also required. The parameters used for modeling are listed in Table 4.

Table 3. PC-SAFT NIF parameter

NIF

Molecular weight 346.36

Segment number (mol/g) 0.023474382

Segment diameter (A) 3.581025

Dispersion energy (K) 309.4425

Association energy (-) 1221.582

Association volume (K) 0.02

Melting temperature (°C) 172

33

Table 4. Binary interaction parameters

k

ijk

NIF-water 0.011k

NIF-PVAC -0.0182717k

water-PVAC -0.172k

NIF-Resomer 0.009k

water-Resomer 0The pure substance and binary parameters presented above arise from adjusting the

experimental from [25] to the theoretical model. In the Figure 24 below, it can be seen the

adjustment of the data with the parameters presented above.

0,0 0,2 0,4 0,6 0,8 1,0

0,000 0,005 0,010 0,015 0,020 0,025 0,030

RH (%) wH2O

34 4.2 Predicting the influence of humidity on the phase behavior

Amorphous API formulations are prone to absorb water from the surrounding atmosphere.

This water absorption leads to a crystallization of the NIF, which is a fact to avoid in order to

keep the properties and bioavailability achieved with the amorphous state.

For this purpose, it is an important issue to predict the effect of humidity on the system

behavior. Therefore it was studied the water sorption of the samples depending on the relative

humidity and temperature under which the samples were being tested.

Sorption diagrams for 60%, 75% and 90% of relative humidity are shown in the next Figures

23, 24 and 25.

As it can be observed, there is a vast contrast between the humidities. At a 75% RH, the

sample is able to absorb a maximum value of water of 0,024 in the amorphous state, while at

90% RH it is able to assimilate 0.047 of water and at 60% RH a maximum value of 0.015.

The upper line, represented by triangles, corresponds to the water content accepted by the

amorphous formulation and the lower line corresponds to the water content accepted by the

crystalline formulation. In this way, it is understood the shape of the Figure 10 in which a

maximum water value is obtained in the amorphous state and as the crystallization advances

the water content decreases.

0,0 0,2 0,4 0,6 0,8 1,0

0,00 0,01 0,02 0,03 0,04 0,05 0,06

w

NIF 80%, 40°C, 60% RH

w

NIF

wH2O

35

0,0 0,2 0,4 0,6 0,8 1,0

0,00 0,01 0,02 0,03 0,04 0,05 0,06

wNIF 80%, 40°C, 75% RH

wNIF wH2O

Figure 26. Sorption diagram for sample wNIF 80%, 40°C, 75°RH

0,0 0,2 0,4 0,6 0,8 1,0

0,00 0,01 0,02 0,03 0,04 0,05 0,06

wNIF 80%, 40°C, 90% RH

wNIF wH2O

Figure 27. Sorption diagram for sample wNIF 80%, 40°C, 90°RH

Based on these data, it is easily predictable that there will be a sizeable difference both in time required to reach the equilibrium and initial and final water value between the samples.

36

0,0 0,2 0,4 0,6 0,8 1,0

0,00 0,01 0,02 0,03 0,04 0,05

0,06 wNIF 80%, 35°C, 75% RH

wNIF wH2O

Figure 28. Sorption diagram for sample wNIF 80%, 35°C, 75°RH

0,0 0,2 0,4 0,6 0,8 1,0

0,00 0,01 0,02 0,03 0,04 0,05 0,06

wNIF 80%, 30°C, 75% RH

wNIF wH

2O

Figure 29. Sorption diagram for sample wNIF 80%, 30°C, 75°RH

4.3 Results of suspension balance experiments

The solid dispersions were placed under the desired conditions of temperature and pressure in

the suspension balance.

Firstly, it was decided to set a sample and conditions as a point of reference. This was an NIF

weight fraction of 80%, a temperature of 40 °C and a RH of 75%. And in order to guarantee

its reproducibility, the experiment was repeated twice. In order to have the same

37

The data collected from the balance system are weight of the sample and the cell where the

powder is; it was also weighted the cell empty. From this weight of the cell and powder and

the weight of the cell itself, it can be calculated the water content in the sample.

As it can be seen in Figure 30, both experiments overlap each other reaching the same water

content at the beginning and at the end and achieving the equilibrium at the same time.

0 15 30 45 60 75

0,000 0,005 0,010 0,015 0,020 0,025 0,030 0,035 Water content

(%)

Time (h)

wNIF=80%

wNIF=80%

Figure 30. Overlap of the two independent water sorption measurements obtained for wNIF=0.80 at 40

°C, 75% RH to check the reproducibility of the experiments

Once this was assured, it was proceeded to study the effect of the influencing factors, always

taking these values as reference.

4.3.1 Influence of wNIF

Different weight fractions of the compounds were tested in experiments; these were 90%,

85%, 80%, 75% and 70% of NIF. The temperature and relative humidity were 40°C and 75%,

respectively. The results obtained can be seen in Figure 29.

As it can be observed, there is an evolution in every case. The higher concentration of API in

38

And also the lower concentration of API the sample contains, the longer it takes to

crystallizes.

0 25 50 75 100 125

0,000 0,005 0,010 0,015 0,020 0,025 0,030 0,035 Water content

(%)

Time (h)

w

NIF=0,7 wNIF=0,75

w

NIF=0,80

wNIF=0,85 wNIF=0,9

Figure 31. Evolution of water content along the weight fraction

In order to avoid the crystallization of NIF, it will be always to work with a low API

concentration. However, it could be the case that with that weight fraction does not reach the

recommended dose, in that case it would have to reach a compromise between the weight

fraction and the improved properties achieved and the recommended dose. On the other side,

future investigations would go in the direction of studying lower API weight fractions.

This can be explained, as it was described in 2.3 Influence of RH on the phase behavior, due

to the shape of the curve in Figure 10.

4.3.2 Influence of RH

The effect of the relative humidity in the crystallization was also studied. RH of 90%, 75%

and 60% were analyzed. The conditions under which the experiments were performed were:

wNIF = 0.80, 40°C of temperature and the corresponding RH.

39

15 30 45 60 75 90 105 120

0,000 0,005 0,010 0,015 0,020 0,025 0,030 0,035

60% RH 75% RH

90% RH

Water content (%)

Time (h)

Figure 32. Evolution of water content along RH

As it can be observed in the previous plot, there is a sizable difference between the

experiments both in initial and ending water content and time to reach the equilibrium. The

higher RH, the higher water absorption, which translates into greater molecular mobility,

which leads to greater crystallization [35].

This behavior was also found in [26].

4.3.3 Influence of Temperature

Another influencing factor that has been analyzed is the temperature. The temperatures

studied were 30, 35 and 40 °C with NIF weight fractions of 90, 80 and 70%. The RH was

40

0 25 50 75 100 125 150

0,000 0,005 0,010 0,015 0,020 0,025 0,030 0,035

wNIF=90%,35°C

wNIF=90%,40°C

wNIF=90%, 30°C

Water content (%)

Time (h)

Figure 33. Evolution of water content along temperature for wNIF 90% and 75%RH

As it is observed in Figure 33, the temperature affects the crystallization time. Comparing the

temperatures with our reference of 40°C, it is perceived an appreciable difference between

them.

0 25 50 75 100 125 150

0,000 0,005 0,010 0,015 0,020 0,025 0,030 0,035

wNIF=80%, 35°C

wNIF=80%, 40°C Water content

(%)

Time (h)

wNIF=80%, 30°C

41

In the case of wNIF of 80% shown in Figure 34, the difference is even greater than before as it

was reached a week time without the 30 °C curve began to decline.

For the 70% NIF sample observed in Figure 35, it can be seen a considerable difference again.

In this NIF weight fraction, the experiment was not performed at 30 °C as it would have been

obtained a straight line similar to the 35°C line.

0 25 50 75 100 125 150

0,000 0,005 0,010 0,015 0,020 0,025 0,030 0,035

wNIF=70%, 40°C

wNIF=70%, 35°C

Water content (%)

Time (h)

Figure 35. Evolution of water content along temperature for wNIF 70% and 75%RH

According to the results, the temperature conditions in order to prevent crystal formation are

the lowest possible temperature.

4.3.4 Influence of polymer type

Another influencing factor studied was the polymer type. It was studied 2 polymers:

Resomer® R203 S and PVAC. Regarding to the final polymer, this was investigated 2

different molecular weights. The results can be seen in Figure 36.

As it is shown, there is a contrast between the two polymers in both the crystallization time

and water content. The polymer Resomer® R203 S took less time to crystallize and reached

42

It can be also noticed the different behavior between the polymer with differing molecular

weight although they accomplished the same initial and ending water content.

0 25 50 75

0,000 0,005 0,010 0,015 0,020 0,025 0,030 0,035

Resomer 203s PVAC350

PVAC90

Water content (%)

Time (h)

Figure 36. Evolution of water content along polymer for wNIF 80%, 40°C and 75%RH

4.3.5 Influence of the method to prepare the formulation

The last influencing factor studied was the method used in order to prepare the formulation.

Two forms of preparation were taken into account: spray drying, as the method used in all the

experiments performed, and melting cooling as the method used in real manufacturing.

43

0 25 50 75

0,000 0,005 0,010 0,015 0,020 0,025 0,030 0,035

melt cooling

Water content (%)

Time (h)

spray drying

Figure 37. Evolution of water content along the method to prepare the formulation for wNIF 80%,

40°C and 75%RH

In Figure 37, it can be seen that almost the same initial and ending values of water content are

achieved.

On the other side, the difference in time to crystallize is appreciable. The time needed for the

sample made by melting process is lower than the spray drying sample.

This is an interesting issue since it is question of avoiding crystallization in time, and this

melting cooling is the method used in industry.

Calculation of crystallinity via mass balance

Once the suspension balance experiments were done, from the water content data obtained

from them, it was proceeded to calculate the degree of crystallinity by mass balances.

44

Table 5. Degree of crystallinity of the samples by mass balances

Polymer wNIF (%) T (°C) RH (%) wCrystals (%)

PVAC 90 40 75 89

PVAC 80 40 75 73

PVAC 70 40 75 63

PVAC 90 35 75 86

PVAC 80 35 75 72

PVAC 70 35 75 18

PVAC 90 30 75 90

PVAC 80 30 75 6

PVAC 80 40 90 79

PVAC 80 40 60 74

PVAC350 80 40 75 73

Resomer 203s 90 40 75 87

Resomer 203s 80 40 75 82

Resomer 203s 70 40 75 70

PVAC 85 40 75 76

PVAC 75 40 75 69

PVAC Meltcool 80 40 75 74

PVAC Meltcool 70 40 75 60

As it can be observed in the previous Table 5 the higher degree of crystallinity was reached

always with a wNIF of 90%. It is also noted that the way of preparation of the formulation

(spray drying or melting-cooling) does not interfere in the crystallinity achieved even though

it does interfere in the process of absorbing water.

The progress of the different concentrations in the system can be observed in the next Figure

38 and 39 for the reference sample (wNIF 0.80, 40°C, 75% RH). It is appreciable that the drop

of the API in the liquid phase coincides with the increase of crystal growth and at the same

45

0 10 20 30 40 50 60 70

0,0 0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,8 0,9 1,0 W Time (h)

wPol in L

wAPIF in L

wH2O L

Figure 38. Concentration of compounds in the liquid phase for reference sample (wNIF 80%, 40°C,

75%RH)

0 10 20 30 40 50 60 70

0,00 0,01 0,02 0,03

wWATER wAPIL

Time (h) wCRYST wCRYST wAPIL wWATER 0,0 0,2 0,4 0,6 0,8 1,0 0,0 0,2 0,4 0,6 0,8 1,0

Figure 39. Evolution of concentration of crystals, water and API for reference sample (wNIF 80%,

40°C, 75%RH)

According to what was seen in previous sections, as the water content decreases, the degree of

crystallization of the sample increases so the NIF content in the liquid phase decreases, as it

can be observed in Figure 39.

The plots of the development of concentrations for the rest of the samples can be seen in

46 4.4 Results of PXRD and DSC-measurements

During this chapter it will be shown the results of the PXRD and DSC measurements. By

performing these experiments, it was wanted to guarantee the amorphous state of the sample

right after the spray drying and before the experiment in the suspension balance and the

crystalline state after the suspension balance. It was also wanted to calculate the melting

enthalpy and therefore verify the degree of crystallinity.

In the next Figures 40 and 41, it is shown the results from PXRD in which the amorphous and

crystalline states of the reference sample can be seen, that is wNIF of 80%, 40°C and 75% of

RH.

Figure 40. PXRD pattern of amorphous state of sample wNIF 80%

![Figure 1. Scheme of spray drying method [6]](https://thumb-us.123doks.com/thumbv2/123dok_es/5475408.725924/20.892.175.711.625.938/figure-scheme-spray-drying-method.webp)

![Figure 2 Hot melt extrusion process [7]](https://thumb-us.123doks.com/thumbv2/123dok_es/5475408.725924/22.892.174.720.205.428/figure-hot-melt-extrusion-process.webp)

![Figure 6. Behavior of solubility against temperature and API weight fraction [10]](https://thumb-us.123doks.com/thumbv2/123dok_es/5475408.725924/25.892.234.660.256.567/figure-behavior-solubility-temperature-api-weight-fraction.webp)

![Figure 9. Behavior of NIF solubility [10]](https://thumb-us.123doks.com/thumbv2/123dok_es/5475408.725924/27.892.46.841.142.349/figure-behavior-of-nif-solubility.webp)

![Figure 10. Behavior of water content and phases during crystallization for a w NIF 70% [10]](https://thumb-us.123doks.com/thumbv2/123dok_es/5475408.725924/28.892.131.770.485.730/figure-behavior-water-content-phases-crystallization-w-nif.webp)

![Figure 13. Characteristic sigmoidal curve followed by crystallization [16]](https://thumb-us.123doks.com/thumbv2/123dok_es/5475408.725924/35.892.169.725.244.526/figure-characteristic-sigmoidal-curve-followed-crystallization.webp)

![Figure 16. Molecular structure of NIF polymorphs [23]](https://thumb-us.123doks.com/thumbv2/123dok_es/5475408.725924/38.892.227.684.435.637/figure-molecular-structure-of-nif-polymorphs.webp)