Design, fabrication and characterization of a high speed, bimodal, CMOS MEMS resonant scanner driven by temperature gradient actuators

Texto completo

Figure

Documento similar

The simulation technique described in previous section has been applied to simulate the system described in equations (10) to (12). To test the speedup of the proposed method,

In the first step, the total images were obtained based on the two-step process by measuring the scattered fields first and then obtaining the focused field by application of

We propose to model the software system in a pragmatic way using as a design technique the well-known design patterns; from these models, the corresponding formal per- formance

At the highest temperature (100°C), an initial decrease of the resistance upon exposure to low concentration of ethanol (800 ppm) (figure 14) is observed, then at higher

For the elliptical resonator fabricated by the hybrid approach it has been measured the resonance frequency, but still more effort in the fabrication process is needed in order

In this paper, useful design hints for designing oscillator circuits based on NOT gates are supported by analyzing the response of the RO in the time domain; ROs have been designed

In this study the ANN model is developed based on the exper- imental results of surface roughness obtained from Taguchi’s design for experimentation and prediction of surface

The impact tester is useful to determine some important design parameters like: energy to produce incipient damage [11-12], peak impact force, energy perforation threshold [14],

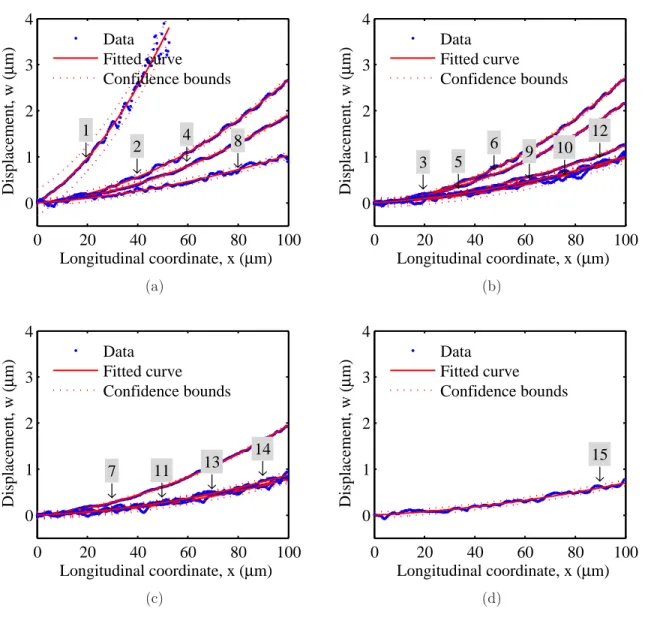

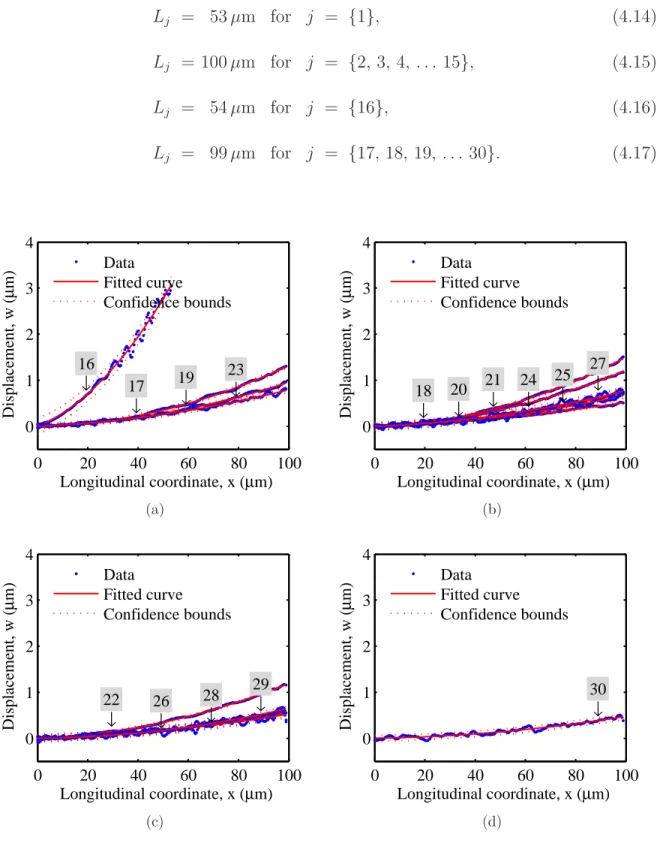

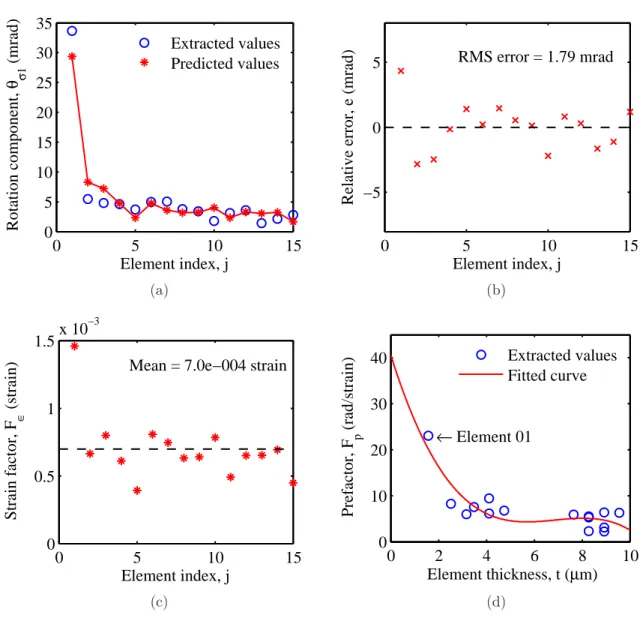

![Figure 4.4: Interferometric surface profiles of the elements in the CMOS-MEMS test structures: (a) TS01 and (b) TS11 [Equipment: Veeco WYKO NT 3300 optical profiler].](https://thumb-us.123doks.com/thumbv2/123dok_es/2269872.514063/62.918.111.774.137.426/figure-interferometric-surface-profiles-elements-structures-equipment-profiler.webp)

![Figure 4.5: Extracted deflection profiles of the elements in the CMOS-MEMS test structure: (a) TS01 and (b) TS11 [Equipment: WYKO NT 3300 optical profiler].](https://thumb-us.123doks.com/thumbv2/123dok_es/2269872.514063/63.918.212.736.185.993/figure-extracted-deflection-profiles-elements-structure-equipment-profiler.webp)