WEAR AND FRICTION BEHAVIOR OF POLY (METHYL METHACRYLATE)/CALCIUM OXIDE COATING COMPOSITES UNDER DRY CONDITIONS

Texto completo

Figure

Documento similar

The sample with medium dimple density (MDD) was the most wear resistant material, showing a wear volume reduction of more than 41% with respect to control sample under high load

Wear test for NiCoCrAlY specimens has shown smaller weight losses and lower friction coefficient under high temperature, meanwhile CoNiCrAlY coating shows a unexpected ware rate

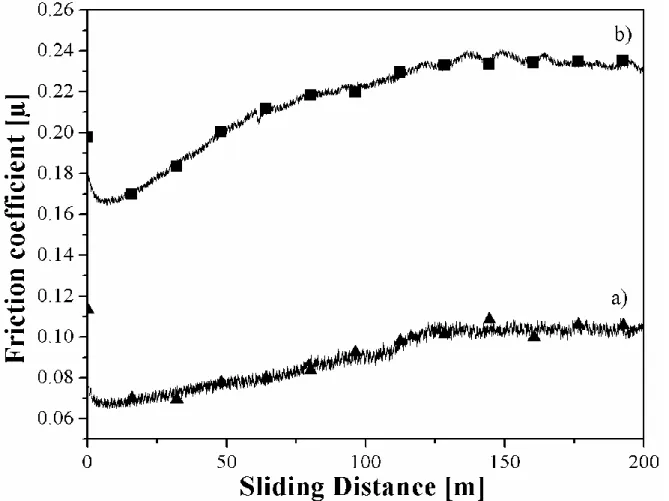

In Figure 2 we show the results of the functionalized graphene as reinforcements for UHMWPE-based composites. After running-in period, friction coefficient for the

Layers with the fiber oriented in the sliding direction showed larger wear due to cracks existing in the fiber- matrix interface once the wear depth reached the fibers.. The

Therefore, in the present study, the formation of the PIL boundary layer on AISI316L stainless steel under static conditions is described in order to prevent or reduce the

The friction torque in rolling bearings produced by these greases was measured and the coefficients of friction under boundary and full film lubrication were numerically

- The drastic reduction of the fluid flow, associated with the better results of surface roughness and roundness errors of the workpiece, and the decrease of the wheel wear caused

% IL in MG reduced one order the magnitude the wear rate of steel disk, with respect the commercially wind turbine gearbox lubricant.. Under the loads studied, the lowest wear