TítuloFatigue performance of bituminous mixtures made with recycled concrete aggregates and waste tire rubber

Texto completo

Figure

Documento similar

aggregates from construction and demolition waste as road base layer. Road Materials and Pavement Design, 1-15. Analysis of chromium and sulphate origins in construction

Se ha incluido un estudio de hormigones considerando la adición de un porcentaje fijo de cemento con la sustitución total del árido grueso natural por reciclado de

- The lower density and higher water absorption values of the TCWA recycled aggregates, compared with the natural limestone and siliceous aggregates, mean that it is necessary to

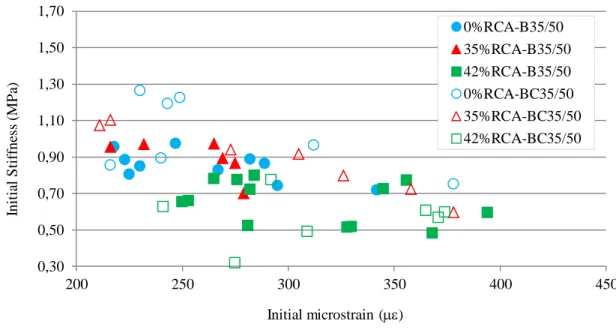

This study employs a test protocol based on a 3-point bending DMA (Dynamic Mechanical An- alyzer) configuration to assess the influence of the type of filler and the bitumen

SEM analysis in the coal refuse sample: (A) compact aggregates; (B) detail with clay aggregates containing different ions; (C) aggregates of phyllosilicates with folded edges;

In all of the measurements, the deflections in the section made with NA, both the base and subbase, were lower than those in sections that used MRA in some structural layers.. In

The combined effect of recycled sand from masonry waste and Nc-FA (M6) only decreases by 3% the mechanical strength of the reference mortar made with siliceous natural sand

However, mortars made with recycled aggregates from CDW are more porous than those made with natural aggregates, which can impair the diffusion leaching phenomena of monolithic