Value Stream Mapping as a Strategic Tool in Lean Transition Waste Elimination and Creation of Value in Different Processes Management

Texto completo

(2) INSTITUTO TECNOLÓGICO Y DE ESTUDIOS SUPERIORES DE MONTERREY CAMPUS MONTERREY DIVISIÓN DE INGENIERÍA Y ARQUITECTURA PROGRAMA DE GRADUADOS EN INGENIERÍA. “VALUE STREAM MAPPING AS A STRATEGIC TOOL IN LEAN TRANSITION” WASTE ELIMINATION AND CREATION OF VALUE IN DIFFERENT PROCESSES MANAGEMENT. TESIS PRESENTADA COMO REQUISITO PARCIAL PARA OBTENER EL GRADO ACADÉMICO DE:. MAESTRO EN CIENCIAS ESPECIALIDAD EN SISTEMAS DE MANUFACTURA EDUARDO SÁNCHEZ SÁNCHEZ. MONTERREY, N. L.. DICIEMBRE 2004.

(3) INSTITUTO TECNOLÓGICO Y DE ESTUDIOS SUPERIORES DE MONTERREY CAMPUS MONTERREY DIVISIÓN DE INGENIERÍA Y ARQUITECTURA PROGRAMA DE GRADUADOS EN INGENIERÍA. Los miembros del comité de tesis recomendamos que el presente proyecto de tesis presentado por el Ing. Eduardo Sánchez Sánchez sea aceptado como requisito parcial para obtener el grado académico de:. Maestro en Ciencias en Sistemas de Manufactura Especialidad en Ingeniería de Producción. Comité de tesis:. ________________________________ M.C. Luis Vicente Cabeza Aspiazu Asesor. _________________________. _______________________. M.C. Alberto Enrique Novau Dalmau. M.C. David González Flores. Sinodal. Sinodal. Aprobado:. ___________________________ Dr. Federico Viramontes Brown Director del Programa de Graduados en Ingeniería Diciembre, 2004. i.

(4) Dedicatoria DEDICATORIA. A mis padres: Rosa María Sánchez Carrillo Roberto Sánchez Ortega Por su apoyo incondicional, la confianza y el amor brindado para siempre ayudarme a alcanzar mis metas A mis hermanos: Rosa María Sánchez Sánchez Roberto Sánchez Sánchez Por estar apoyándome siempre en las decisiones realizadas y creer en mi para lograrlas. ii.

(5) Agradecimientos. AGRADECIMIENTOS A Dios por darme la oportunidad de vivir, la salud y la fuerza necesaria para alcanzar las metas propuestas, así como también por las bendiciones que me ha otorgado a lo largo de mi vida Al M.C. Luis V. Cabeza A. por el apoyo, confianza y sus observaciones a lo largo del presente proyecto de tesis. Al M.C. Alberto Novau D. y al M.C. David González F. por su confianza, apoyo y ayuda para concluir adecuadamente este proyecto. A mis padres, hermanos y familiares por su apoyo incondicional en todo momento desde el inicio de mi formación hasta este momento. A mi novia Angélica Espinosa por su gran amor, por creer en mí y por su cariño mostrado para acompañarme e impulsarme a alcanzar esta meta. A mis profesores y amigos de la maestría que gracias a sus consejos, experiencia y conocimientos me ayudaron a salir adelante en este proyecto. A todos los que me apoyaron y permitieron que cumpliera con esta nueva meta personal y profesional que me propuse y ahora es una realidad. iii.

(6) Summary. SUMMARY. The main objective of this work of thesis is the formulation of a frame of reference, by means of an analysis of the application of a Lean Manufacturing tool (Value Stream Mapping) in various processes of diverse companies of different maturity levels in the Manufacturing sector to help them see the optimizations that can be attained trough the use of this tool.. In the development of this thesis, an investigation of Value Stream Mapping (Lean Manufacturing tool) and its strategy of implementation were made. The author of the present document made a series of practical cases applying this tool with the purpose of making an analysis in order to find the most important elements and than that would be useful to integrate them in a frame of reference.. Once realized the analysis, the author developed and proposed a model as well as a frame of reference that can serve as guide for people whom they want to use the value stream map tool. The results obtained when applying the practical cases offer interesting results that allow to see the benefits that an organization could obtain when doing use of a tool like this, as well as, this investigation allows to see possible future investigations that they reinforce and they improve the model and the frame of reference proposed here.. iv.

(7) Contents CONTENTS. SUMMARY ........................................................................................................................ IV CONTENTS ........................................................................................................................ V LIST OF FIGURES .......................................................................................................... VIII LIST OF TABLES............................................................................................................. VIII. CHAPTER I.- INTRODUCTION CHAPTER I.- INTRODUCTION.......................................................................................... 2 1.1 INTRODUCTION .......................................................................................................... 2 1.2 PROBLEM DEFINITION............................................................................................... 3 1.3 JUSTIFICATION ........................................................................................................... 4 1.4 OBJECTIVE.................................................................................................................. 6 1.5 HYPOTHESIS............................................................................................................... 6 1.6 SCOPE ......................................................................................................................... 6 1.7 RESULTS ..................................................................................................................... 7 1.8 METHODOLOGY ......................................................................................................... 7 CHAPTER II.- RESEARCH FUNDAMENTALS CHAPTER II.- RESEARCH FUNDAMENTALS................................................................ 10 2.1 INTRODUCTION ........................................................................................................ 10 2.2 LEAN THINKING ........................................................................................................ 10 2.3 LEAN MANUFACTURING.......................................................................................... 11 2.3.1 DEFINITION OF LEAN MANUFACTURING ........................................................... 11 2.3.2 BACKGROUND OF LEAN MANUFACTURING...................................................... 12 2.3.2.1 ORIGINS OF LEAN MANUFACTURING ............................................................. 12 2.3.2.2 BASIS OF TOYOTA PRODUCTION SYSTEM .................................................... 13 2.3.2.3 WASTE DEFINITION ........................................................................................... 15 2.3.2.4 MAIN TOOLS AND TECHNIQUES ...................................................................... 16 2.3.3 IMPLEMENTATION SYSTEM................................................................................. 22 2.4 VALUE STREAM MAPPING ...................................................................................... 25 2.4.1 VALUE STREAM MAPPING DEFINITION.............................................................. 25 2.4.2 INFORMATION AND MATERIALS STREAM ......................................................... 27. v.

(8) Contents 2.4.3 VALUE STREAM MANAGER.................................................................................. 28 2.4.4 PRESENT VALUE STREAM MAPPING ................................................................. 29 2.4.5 FUTURE VALUE STREAM MAPPING.................................................................... 30 2.4.6 IMPLEMENTATION PLAN ...................................................................................... 31 2.5 HUMAN FACTOR ....................................................................................................... 33 2.5.1 HUMAN FACTOR IN THE ORGANIZATIONS ........................................................ 33 2.6 AUTOMOTIVE INDUSTRY ........................................................................................ 35 2.7 ELECTRONIC INDUSTRY ......................................................................................... 38 2.8 AEROSPACE INDUSTRY.......................................................................................... 42. CHAPTER III.- CREATION AND ANALYSIS OF PRESENT AND FUTURE VSM CHAPTER III.- CREATION AND ANALYSIS OF PRESENT AND FUTURE VSM .......... 47 3.1 INTRODUCTION ........................................................................................................ 47 3.2 INVOLVEMENT OF THE COMPANIES IN THE PROJECT ...................................... 47 3.3 PRESENT AND FUTURE VSM.................................................................................. 48 3.4 VALUE STREAM MAPPING MODEL ........................................................................ 57. CHAPTER IV.- CREATION OF A FRAME OF REFERENCE CHAPTER IV.- CREATION OF A FRAME OF REFERENCE .......................................... 62 4.1 INTRODUCTION ........................................................................................................ 62 4.2 ¿WHAT IS A FRAME OF REFERENCE?................................................................... 62 4.3 FRAME OF REFERENCE DESIGN ........................................................................... 63 4.4 FRAME OF REFERENCE .......................................................................................... 64. CHAPTER V.- CONCLUSIONS CHAPTER V.- CONCLUSIONS ....................................................................................... 69 5.1 INTRODUCTION ........................................................................................................ 69 5.2 CONCLUSIONS ......................................................................................................... 69 5.3 LIMITATIONS ............................................................................................................. 76 5.4 RECOMMENDATIONS FOR FUTURE RESEARCHES............................................ 76. CHAPTER VI.- BIBLIOGRAPHY AND REFERENCES 6. 1 BIBLIOGRAPHY AND REFERENCES...................................................................... 79. vi.

(9) Contents CHAPTER VII. ANNEXES ANNEX 1 LEAN MANUFACTURING TOOLS .................................................................. 83 ANNEX 2 VALUE STREAM MAPPING ICONS ............................................................... 84 ANNEX 3 VALUE STREAM MAPPING MODEL .............................................................. 87 ANNEX 4 PRESENT VALUE STREAM MAPPING CASE 1 ............................................ 88 ANNEX 5 FUTURE VALUE STREAM MAPPING CASE 1............................................... 89 ANNEX 6 PRESENT VALUE STREAM MAPPING CASE 2 ............................................ 90 ANNEX 7 FUTURE VALUE STREAM MAPPING CASE 2............................................... 91 ANNEX 8 PRESENT VALUE STREAM MAPPING CASE 3 ............................................ 92 ANNEX 9 FUTURE VALUE STREAM MAPPING CASE 3............................................... 93 ANNEX 10 PRESENT VALUE STREAM MAPPING CASE 4 .......................................... 94 ANNEX 11 FUTURE VALUE STREAM MAPPING CASE 4 ............................................ 95 ANNEX 12 PRESENT VALUE STREAM MAPPING CASE 5 .......................................... 96 ANNEX 13 FUTURE VALUE STREAM MAPPING CASE 5 ............................................ 97 ANNEX 14 PRESENT VALUE STREAM MAPPING CASE 6 .......................................... 98 ANNEX 15 FUTURE VALUE STREAM MAPPING CASE 6 ............................................ 99. vii.

(10) List of Figures and Tables. LIST OF FIGURES FIGURE 1 DETERMINANTS OF THE NATIONAL COMPETITIVE ADVANTAGE. . . . . . .5 FIGURE 2 METHODOLOGY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 FIGURE 3 VALUE STREAM MAPPING STEPS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 FIGURE 4 CONTINUOUS IMPROVEMENT IN VSM . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 FIGURE 5 MATERIALS AND INFORMATION FLOWS . . . . . . . . . . . . . . . . . . . . . . . . . . 27 FIGURE 6 NATIONAL SALES [AMIA] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 FIGURE 7 VEHICLES EXPORTATION [AMIA] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36 FIGURE 8 AEROSPACE INDUSTRY STRUCTURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 FIGURE 9 VALUE STREAM MAPPING FIRST PHASE. . . . . . . . . . . . . . . . . . . . . . . . . . 49 FIGURE 10 VALUE STREAM MAPPING SECOND PHASE. . . . . . . . . . . . . . . . . . . . . . .51 FIGURE 11 PRESENT STATE ANALYSIS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52 FIGURE 12 VALUE STREAM MAPPING THIRD PHASE. . . . . . . . . . . . . . . . . . . . . . . . .53 FIGURE 13 VALUE STREAM MAPPING FOURTH PHASE. . . . . . . . . . . . . . . . . . . . . . .55 FIGURE 14 SCHEMATIC REPRESENTATION OF THE VSM MODEL. . . . . . . . . . . . . . 57 FIGURE 15 VALUE STREAM MAPPING MODEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58. LIST OF TABLES TABLE 1 ELECTRONIC INDUSTRY BRANCHES [SECRETARY OF ECONOMY]. . . . .40 TABLE 2 LEAD-TIME CONCLUSIONS BY CASE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69 TABLE 3 IMPROVEMENT PROJECTS BY CASE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70. viii.

(11) Chapter I.- Introduction. CHAPTER I.- INTRODUCTION. 1.

(12) Chapter I.- Introduction. CHAPTER I.- INTRODUCTION. 1.1 INTRODUCTION Presently, diverse changes have occurred in the markets worldwide due to Globalization, resulting in the revolution of many aspects of life, and particularly, the economic and technological areas, concerning the production of goods and services.. It is because of this that, in order to keep themselves attractive to their clients, as well as competitive in the market, the companies in the Manufacturing1 sector must look for the elimination of wastes as well as the reduction of costs by means of a quality improvement of all their processes, products and services. Often, however, the resources of the companies are too limited, which is why the investments must be assigned after a careful selection of those projects that promise to grant the best results. In Mexico, it is desired to lead the suppliers in the Manufacturing sector up to a level of worldwide class competitiveness, which demands a fairly high level of quality. It is because of this that Mexican companies have committed themselves with the improvement of their production processes, as well as the increasing of the quality level of their products.. Nowadays, there is an abundance of many tools and quality practices that can be implemented in the Mexican companies in the Manufacturing sector in order to help them improve their current manufacturing systems, same as to rise them up to a sufficiently high level of competitiveness to become a worldwide class company.. 1. Manufacturing Sector, integrated by diverse sectors like Automotive, electronic, between others.. 2.

(13) Chapter I.- Introduction. 1.2 PROBLEM DEFINITION In a world in which day after day the Organizations have to create new products and make improvements to the existing ones, there is a strong competition between companies to hold their clients, and so, the companies are always looking for a way to reduce their operation costs, eliminate wastes in all their processes, and increase the quality of their products.. Then, with so many options of offered products and services, the companies have realized the necessity to compete in the maximum fulfilling of the requirements of the client, as well as to maintain themselves in the technological vanguard that a competitive word like ours demand.. By means of an appropriate application of these modern tools, one looks for the satisfaction of the client’s expectations trough the optimization of the resources that take part in the process of creation of the product, always trying to maintain a continuous improvement cycle in order to achieve the level of a worldwide class company.. Given the strategic importance of Mexico in the Manufacturing sector, which more and more is becoming highly competitive and evolutionary, it must look for a way to constantly minimize and, if possible, eliminate the lose of competitiveness that it faces at the moment. Since it is desired to establish Centers of Manufacture and Joint in Mexico, it is priority to start developing reliable suppliers of 2nd and 3rd level that count on better practices of Quality, Manufacture, and fulfillment of the demanding norms of the Manufacturing sector.. It is because of the former that the established companies on the Manufacturing sector in the north-east of Mexico, as well as those looking to introduce themselves in the industrial sector, are now facing the problem of finding. 3.

(14) Chapter I.- Introduction. themselves below the international standards, in terms of quality in the application of the techniques, update of technology and improvement of administrative and operating practices.. Therefore, the analysis of the mapping as a Lean Manufacturing tool arises as an opportunity area in diverse companies, in different functions that help to visualize and plan the optimization levels that can be attained.. 1.3 JUSTIFICATION The obtaining of an analysis trough the use of a Lean Manufacturing tool in the Companies of the Manufacturing sector of the north-east of Mexico will help to obtain a frame of reference to show the companies the improvements that can be made in their processes, as well as the growth that is expected to be reflected in competitive their competitive advantage [Porter], not only in a national, but in an international level, leading to an increase in their gains after the elimination of waste in their companies.. The most significant benefits that will be achieved by means of this analysis stand for the creation of a frame of reference, by means of which, the companies of the manufacturing sector will be able to see how the value for the client is created or identified in several types of companies; as well as the establishing of the advantages linked to the use of a Lean Manufacturing tool for the identification and elimination of the waste.. With regard to the mentioned competitive advantages, one is based on the investigations made by Michael Porter, in which the most important points of the present project are based. Said points are illustrated in the following diagram.. 4.

(15) Chapter I.- Introduction. Intensity of the rivalry. Conditions of various factors. National Competitive Advantage. Conditions of local demand. Competitivity of Support Industries and related. Figure 1 Determinants of the national competitive advantage [Porter]. Therefore, the competitive advantages for a company can be given in a particular way under these conditions:. 1. The country has the suitable combination of basic and advanced production factors to support that industry.. 2. The intense rivalry between local companies in that field forces them to be efficient.. 3. The strong conditions of local demand have helped to establish a local solid industry due to the demands of the clients, which force the companies to develop a greater level of efficiency.. 4. The support companies and alike are competitive to an international level, thus providing low cost, high quality products to the complementary organization located in the main industry.. 5.

(16) Chapter I.- Introduction. 1.4 OBJECTIVE. The objective of this work of thesis is the formulation of a frame of reference, by means of an analysis of the application of a Lean Manufacturing tool in various processes of diverse companies of different maturity levels in the Manufacturing sector to help them see the optimizations that can be attained trough the use of this tool.. 1.5 HYPOTHESIS. The creation of a frame of reference in which the companies can see the advantages liked to the application of a Lean Manufacturing tool that creates value for the client will be reflected in terms of a high competitiveness in the market, opportunities of growth, long term survival, and greater income in the companies. Said frame of reference is based on the recognition of the value created for the client as such, and as the reason for which they accept products or services.. 1.6 SCOPE. This work of thesis will contemplate several areas such as Planning, Quality, Production, as well as the use of the Lean Manufacturing tool of Value Stream Mapping. In addition, it work will focus in one of the crucial points that concerns Lean Manufacturing: the Human Factor, which is the key factor for the success of Lean Manufacturing and for other endeavors implemented in the enterprises.. The companies with which this project will deal are those organizations of the Manufacturing sector of the north-east of Mexico (states of Nuevo Leon, Tamaulipas, Coahuila and Chihuahua) that are already established, and also those that are yet being developed, since they stand for a strong point where it is possible to be focused, and in which the use of Value Stream Mapping is suitable.. 6.

(17) Chapter I.- Introduction. 1.7 RESULTS. The desired attained result is an analysis by means of a Lean Manufacturing tool in different types of companies in different stages from maturity inside the Manufacturing sector, leading to the establishing of a frame of reference trough which, the companies of said sector, can see the improvements that can be obtained when properly applying Lean Manufacturing tools.. 1.8 METHODOLOGY. This methodology begins with the analysis of the Automotive, Electronic and Aerospace Benchmark of the CSIM 2003-2004, which provides the corresponding information to focus in the second and third suppliers, and, in an equal way, in the important points within the company.. The method that is described next intends to be used in several Companies of the Manufacturing sector to make the corresponding analysis, in such way that other companies of the sector can see the improvements that can be obtained in their processes with the application of Lean Manufacturing tools.. Step 1. Bibliographical Research.. Step 2. Creation of present state and future state value stream mappings of companies inside the manufacturing sector.. Step 3. Collection of the obtained information from the Value Stream Mappings in order to make an analysis which can help to create a frame of reference for more companies of the Manufacturing Sector.. 7.

(18) Chapter I.- Introduction. Step 4. Creation of a frame of reference for companies of the manufacturing sector that lead to the optimization of its area of Manufacture. In addition, the obtained results will be presented in a written form.. Analyze results. Action Plan and Implementation Bibliographical Research. Proposals of improvement projects. Creation of a frame of reference. Creation of Future Value Stream Mappings. Creation of present Value Stream Mappings. Analysis of the Present Value Stream Mappings. Figure 2 Methodology. 8.

(19) Chapter II.- Research Fundamentals. CHAPTER II.- RESEARCH FUNDAMENTALS. 9.

(20) Chapter II.- Research Fundamentals. CHAPTER II.- RESEARCH FUNDAMENTALS. 2.1 INTRODUCTION In this chapter are the fundamental concepts of the Methodologies of Lean Manufacturing and Six Sigma, as well as the corresponding theoretical frame within the Manufacturing sector. The objective of the same one is to show the essentials of each one of the factors considered in this thesis, towards this offer one first vision of the basis exposed here, as well as the departure point of the later analyses.. 2.2 LEAN THINKING Firstly to understand suitably the concept of Lean Manufacturing, the definition of Lean Thinking will be observed with inclusion of the strategic thought, that it is a powerful model of the competitive organization who is based on the common sense of the strategy of Administration, combining the processes of continuous improvement and the integration of the supply chain in its totality.. The Lean thinkers persecute their objective through a simple process of 5 steps:. 1. Specify the VALUE correctly from the perspective of the client. 2. Identify the VALUE STREAM for the solution and elimination of steps that cause waste. 3. Do that the remaining steps in the process design-construct-maintain flow. 4. Introduce “Pull” design systems, orders and maintenance of the client to replace "push" systems historical based on predictions. 5. Administration trending to perfection. Subsequently, two essentials practices in a Lean Enterprise are, 10.

(21) Chapter II.- Research Fundamentals. 1. The extension of the definition of Value outside the company, this is to involve to suppliers of products and services, partners and clients (Extended Enterprise). 2. Promote a culture of Continuous Improvement, based in quality and effectiveness.. So that a company is Lean, first it must have a complete understanding of what it is what their clients value and to focus to these necessities with the appropriate definition of the value stream within the company, as well as throughout the Supply Chain. If VALUE is defined like all those activities by which the client is willing to pay, it arise the necessity to eliminate and/or reduce all those activities that creates waste in the different Value Stream.. 2.3 LEAN MANUFACTURING. 2.3.1 DEFINITION OF LEAN MANUFACTURING It is a strategy to obtain significantly a continuous improvement in its development through the elimination of all the wastes of time and resources in the total process of the company. Lean Manufacturing combines the advantages of the Handmade Production and Mass Production avoiding the high cost of the first one and the rigidity of the last one. The Lean producers use teams of multidisciplinary workers in all the levels of the organization and use highly flexible machines and more and more automated to produce high volumes and variety. [Womack Et al, 1990].. It was called "Lean" because it uses less human resource, less space of the factory, less investment in tools, less hours of engineering to develop a new. 11.

(22) Chapter II.- Research Fundamentals. product, less inventory, produces less defects and great amount of variety of products. [John Krafíck, 1991]. In other words, Lean Enterprises focus in the perfection through reduction of the waste: in reducing the costs continuously, the defects, the inventories and increasing the variety of products.. 2.3.2 BACKGROUND OF LEAN MANUFACTURING It is a Methodology that was developed by Toyota and at the moment it is used by many companies in the world, known like Toyota Production System. Other companies adopted the system according to their own necessities and they assigned an own name to him, like Delphi which call it Delphi Production System. Therefore the term Lean Manufacturing is a more generic term and talks about the principles and the development of the Lean concept.. 2.3.2.1 ORIGINS OF LEAN MANUFACTURING In order to know the origins of LM, it is necessary to review the systems established by Taiichi Ohno in the Toyota organization that compared the operation of a factory with the operation of the human body where all the systems respond automatically and synchronously when a problem arises.. Some of the techniques used by the company to be able to avoid the difficulties that faced which took it which nowadays it is known as Lean Manufacturing. [Ohno, 2000]. The main objective of the Toyota Production System was to make many models in small amounts. The base of the system is the absolute elimination of excessive, that is, the absolute elimination of the unproductive remainders and to. 12.

(23) Chapter II.- Research Fundamentals. eliminate these remainders will be necessary to identify them. The term “Lean” is very appropriate because one of the points to attack is to eliminate the excesses or wastes in the processes of manufacture and the organization. Waste is defined as any thing that does not add value to the product desired by the costumer. It could also be defined as any thing that the costumer is not willing to pay for.. 2.3.2.2 BASIS OF TOYOTA PRODUCTION SYSTEM The Toyota Production System has as primary target the reduction of cycle times through the elimination of waste. The fundamental idea of this system is to maintain a continuous flow of products in a flexible way to adapt to the changes plaintiffs. "We are improving the time of the line, as the moment at which our client issues an order to us until the moment for receiving the money. The form to reduce the time of the line is eliminating the activities that do not generate some added value in process." [Ohno, 1988]. As secondary results, it obtains the diminution of the inventories levels and the best use of the work force, thus increasing, the productivity and diminishing the costs.. Both pillars in which the system is sustained are: 9 Just in time (JIT) 9 Autonomatizacion - Jidoka. The first base of the Lean System, Just on time, means that in a continuous process, the necessary suitable pieces for the joint must be gotten up exactly to the line of joint at the single moment in which they are needed and in the amount in which they are needed.. If a final process goes to a beginning process to gather single the correct piece in the necessary amount and the concrete moment at which they are needed. 13.

(24) Chapter II.- Research Fundamentals. the single initial process it will only make the number of retired pieces, for this will be necessary that the communication between the processes occurs in a clear way [Ohno, 2000].. To this system where communicates the amount of pieces necessary to use by the initial process and therefore to make by the final process is called Kanban. With this system, the method to transfer materials is reversed, this is the natural flow to produce, to transfer and to give is reversed. This also applies to processes that go beyond your limit of the plant assembler, that is, in a convenient way is applied to suppliers, manufacturing and clients.. Using Just in Time tool a balance of the production settles down, distributes the manufacture in equitable form during the working day. In order to obtain the previous thing one establishes a flow of production and a form to maintain the continuity in the provision of the raw materials of the suppliers to the manufacture. In order to incorporate to the external suppliers it is necessary to listen his conditions and sharing the techniques of how synchronizing the materials with the rate of the line.. The second base of LM, Autonomatizacion, Jidoka is a term that is given to the automation with a human touch. An automated machine with human touch is that machine that is connected to an automatic detection mechanism so that when the machines detect an abnormality stops by them.. The objectives of a corporation must be to give products of a quality, price, and within a time defined previously. JIDOKA is the concept to add an element of the human judgment to the automated equipment. Doing this, the equipment gets to be able to discriminate the unacceptable quality, and the automated process begins to be more reliable.. 14.

(25) Chapter II.- Research Fundamentals. The applications of the Autonomatizacion are very diverse: security, complete work, prevents errors (Poka Yoke). Some of the examples are: 9 When a mechanization error exists, the material will not fit into the tool. 9 If there is some irregularity in the material, the machine will not start up. 9 If there is a mechanization error, the machine will not initiate the process.. This concept not only applies to the machine, also to the line of production and to the workers allowing that they can stop the line to prevent the production with defects and allow investigated which is the situation that originates them.. 2.3.2.3 WASTE DEFINITION To improve the speed of the deliveries is only one of the benefits of Lean Thinking. Lean Thinking works in the reduction or elimination of many types of waste with low cost and respecting the quality that the client demands, this like main points. In Lean Thinking, identify and eliminate wastes it is very important as much so it even counts with its own terminology. In Lean Thinking, waste is called MUDA, which is waste in Japanese.. Lean Thinking identifies seven types of wastes.. 1. Overproduction 2. Correction of defects 3. Unnecessary Inventory 4. Unnecessary Processing 5. Excessive Transportation 6. Inactivity (delay periods) 7. Unnecessary article movement.. 15.

(26) Chapter II.- Research Fundamentals. Additionally, it is considered important to add three types more of wastes: 1. Lack of advantage of human talent 2. Inadequate use of computational systems 3. Work with the wrong metrics [Cabeza L., 2003]. In order to see and eliminate the waste in the work environment a great effort is required, to understand that any thing that does not add value to the product or service that we offer to the clients is waste.. It is by that, we have to identify suitably the 3 types of activities that are developed in the companies to eliminate the unnecessary. a) Activities that add value b) Activities that are not necessaries and does not add value c) Activities that are necessaries that do not add value. With this we can observe that the second type of activities is waste, another reason by why we must eliminated as soon they are identified.. 2.3.2.4 MAIN TOOLS AND TECHNIQUES. 5 S's An essential element in Lean Manufacturing is to maintain in order the workplace. The concept of 5 S's was developed in Japan and its name comes from the initials of the 5 words that form this useful and simple tool. Its application and utility have been universal, and its implementation goes directed to a way to think and a habit about the workplace. The 5 words that form this tool indicate the actions that improve the work environment and are by implementation order. A full description of this tool we can see it in annex 1.. 16.

(27) Chapter II.- Research Fundamentals. Visual Administration. The distinguishing characteristic of the visual administration in the organizations is the way in which the information is organized to be accessible. The distinguishing aspect of the visual administration is its approach towards the group, not exactly towards the individual. However, neither the understanding is limited by the hierarchic positions or the specialized capacities, but by the property to a specific cultural community. This is one of the fundamental differences of the visual administration. The goal in these factories is to extend the community to increase range of information to a greater number of people. When the people are not involved, they can always think that the information talks about its colleagues, supervisors, personnel of quality control, technicians, or directors and these messages does not affect to him directly. A place with visual administration is equipped with a communication structure whose nature is to allow that everything is seen what has meaning and to provide meaning for everything what can be seen [Greif, 1993].. The visual control of the production consists in orienting the units of the production in agreement with the defined directives. The amount and term objectives must be defined, and must make decisions as far as orders of raw materials and pieces, assign human and technical resources, to take the process of manufacture at the appropriate moment and to select priorities in case of overload in the production units.. Kanban is a good example of visual control of the production because it is support by a card system ordered on a board. In agreement with the growth level of cards with a particular bench mark, is immediately clear the necessity to reassume the production.. 17.

(28) Chapter II.- Research Fundamentals. Kanban. In a Lean Manufacturing system the use of communication or visual control is indispensable, which can be made of many forms. One of the more useful tools is the Kanban, which uses signals to obtain a “stretch” production system or "pull system".. The word kanban in Japanese means "visible record”. The Kanban system has been used like technique of control in Just in Time from mid 70's, and is a control used by cards. [Schonberger, 1996]. "KANBAN can be a card, an empty container, or a flag, where a process sends a signal to the previous process that it needs more work in process, in this system, the production rank is determined by the cycles of substitution".[Shingeo Shingo, 1992]. The Kanban system is an information system that maintains in balance the amounts of production in each process. It is a tool of support to the production system of just in time. In this system the information is sent through traveling cards. The card is sent to the personnel of the previous process; like result, many processes of production within a company can be connected and communicated with others. This connection of the processes allows having a better control in the necessary amounts of different variety from products.. Andon. It is a visual control tool to call the attention of the personnel when indicating the existence of a trouble by which the line production has stopped. It means lantern in Japanese, and its name comes by the fact to guide the people in the existence of abnormal conditions. ANDON System under normal operations stays with the green light on, when a worker wants to fit something in the line requests. 18.

(29) Chapter II.- Research Fundamentals. aid through the yellow light. If the line stops the operation and needs rectify a problem the red light it is turned on. An advantage of this type of systems is to offer confidence to the personnel to be able to make the decision to stop the production in case of being necessary; avoiding, the overproduction or production of defective products. [Ohno, 1988]. Pokayoke The Toyota Production System is based on the elimination of wastes; by which when avoiding defects, we are eliminating a great source of waste, not only avoiding defective products, also when avoiding to waste time by inspection and rework; causing diminution of costs. Pokayoke is a Japanese tool that means on approval of error, and consists of creating mechanisms which they offer security to the processes, eliminating any cause of error/defect.. “Pull” System “Pull” System it is a concept focused on the reduction of unnecessary of the product in process (Waste by inventory), is a fundamental element for Just in Time. The concept originally was taken from the American supermarkets in which the empty spaces in the bookcases indicate the employee who must replace the product.. In a traditional system of manufacture by lots, each process of lots in the operation "push" as much to the product as it is possible in the following process of lots since mainly they are measured when coming out. In this system, the successive operations "pull" to the previous operation the work in process. Between the operations a predetermined amount of inventory only can exist. Once it has been reached this amount, it can be necessary to stop the previous operation, unless it is an operation of bottle neck. Even if it is, the procedure still can consider that the operation stops. 19.

(30) Chapter II.- Research Fundamentals. It is common to find the mistaken homologation of the Kanban system of with the Pull system. When there is to consider that the element "Kanban" it is a mechanism that allows that the pull system works with regularity.. Total Productive Maintenance. One. element. that. becomes. elementary. when. implementing. Lean. Manufacturing is the maintenance; in order to allow the good operation of the system of Just in time with the tools before mentioned, the good operation of the machinery or equipment is necessary. The Total Productive Maintenance is a concept that is based on three very simple ideas: 1). Preventive maintenance.. 2). Maintenance History. 3). Delegation of maintenance simple tasks. The establishment of a program of preventive maintenance, the fulfillment of the program in the determined term, the establishment of contingency plans will contribute that the system continues working regularly.. The second point is the existence of a data base with the history of the maintenance, so predicting the failures of the equipment will be simpler within reasonable terms.. Finally the most important idea: delegate the simpler tasks of maintenance to them that better know the equipment. The workers perfectly know the temperature, the sound, the vibration and even the scent and the aspect of their machinery. Thus, when equipment correctly does not work the worker is the one who can recognize it quickly. This generates savings, since instead of leaving the. 20.

(31) Chapter II.- Research Fundamentals. machine awaiting attendance; the workers could lubricate the equipment and conduct other basic or routine operations of maintenance.. SMED. In order to obtain operative flexibility, make the programming feasible and viable of smaller lots it is necessary to take in account the times of preparation from the machines (Setup), since opportunity areas exist to improve within it.. Therefore the reduction of the time of production is one of the fundamental objectives in this world wide level. This time is made up of several elements like preparation of the material, transfers, joint and the time of preparation of the machines (Setup). The time of preparation of the machines has a direct relation with the batch size of production. If the duration of the preparation is reduced also can be reduced the batch size and this entails to the diminution of the total time of production.. It is possible to indicate that the objective is not to reduce the number of operations of joint, but it is reduce all the time used at the diverse moments that the machine is inactivates. SMED consists of separating the process in two types of activities "internals and externals" and to try to eliminate the internal activities.. The internal activities consist of all those activities when the machine is not producing. The external activities are those activities that are made when the machines are working. The premise consists that in many processes the machinery is producing, not the worker, or is not occupied at least to the 100%. Like result, depending on the process and the machinery, the operator can make some tasks of preparation or assembly while the process or the machine is working. This situation can not appear in all the cases, since in totally manual. 21.

(32) Chapter II.- Research Fundamentals. operations they need that the worker is present in his place of work so that the production can be made. The typical tasks consist in obtaining of tools, pieces and materials.. 2.3.3 IMPLEMENTATION SYSTEM Now, the form in which a Lean Company operates according to the strategy of Lean Thinking is given by: 1. Definition of Value. 2. Identify the current or the value stream 3. Make that the material flows 4. Implementation of “Pull” Production System 5. Perfection’s search Define the value:. The Lean strategy begins with VALUE definition from the perspective of the client. The Lean organization defines VALUE like the investment in time and resources in the understanding of the final application of the product provided with the aim "to unearth" the value derived from this by the CLIENT in terms of the product or service. [Womack, 1996]. The VALUE, defined from the perspective of the client, then is aligned within the organization and the activities that add value can be recognized like any activity by which the CLIENT is willing to pay. Identification of the Value Stream It’s the initial tactically important point for the implementation of a Lean Thinking System. The Value must be expressed in terms of a specific product and service that satisfy the necessities of the client to a specific price and in a specific moment. The identification of the value stream is defined as: "the group of all the. 22.

(33) Chapter II.- Research Fundamentals. specific activities required to offer a specific product through the three administrative tasks of all business... the resolution of problems... information management... physic transformation." [Womack, 1996]. Determines what it creates and does not create value from the perspective of the client and not from the perspective of the individual companies, functions and/or departments. It serves to identify when and where the value is being added and where it happen the waste throughout the complete trajectory of the product.. It provides a mean to recognize and communicate easily what is happening, allowing to the members of the equipment identify more easily the sources of waste’s generation, as well as the means for its elimination. Cause that the material flows. The Lean organizations are mainly worried in causing that the materials flow in the system with high levels of "inventory’s returns" without allowing that the material is accumulated or suspended in storage points. The capacity of assure the flow materials within the factory, and derivate VALUE instead cost, implies waste elimination.. Eliminating waste and improving the flow of material improve the answer from the factory to the market allowing that the company works on the real demand instead of the prognoses. The strategy also reduces the costs of manufacture and security inventory returning capital to the Lean Business.. Make that all those actions that create value flow without interruptions, deviations or hopes. This phase marks the conversion of the type of batch operation for a type of cellular operation. The principles of this phase are especially applicable to the manufacture and assemble.. 23.

(34) Chapter II.- Research Fundamentals. Implementation of “Pull” Production System "Pull Production" is a principle that has evolved of an innovation of Toyota. The use of “Pull” techniques allows that the times of delivery are reduced and improves the flow of materials inside and between the organizations.. The application of this concept in the scale of the support flow means that the material will flow, through the complete population of suppliers. It can be used to increase the product synchronization manufactured by order instead of going "guessing" with prognoses that are by nature inexact.. This concept allow that the client is who "pull" the product that needs, more than "push" products (often not wished by the client) towards him. Producing according to the requirements of the client and not according to a prognosis.. Join individual cells within the production system and suppliers with a system where the client is the one who "pull". The success of this phase results from the “Just in Time” production system that begins with the suppliers and finishes with the final client. Perfection’s Search Lean strategy goes beyond a scheme of suggestions and includes the continuous improvement by each worker, each administrator and each supplier of the plant. The Lean producers then develop the required mechanisms to promote and to develop innovations through the factory and to implement them quickly to improve the whole flow of materials in the factory.. The diverse “Lean” techniques and tools implemented in the four previous steps (Definition of Value, Identify the current or the value stream, Make that the material flows and Implementation of “Pull” Production System) are repeated and refined, taking the improvement to the following level (Kaizen).. 24.

(35) Chapter II.- Research Fundamentals. 2.4 VALUE STREAM MAPPING 2.4.1 VALUE STREAM MAPPING DEFINITION VALUE STREAM is all the actions (that add value and that do not add value) that are required to take a product through the principal “streams” of the processes. •. The production flow, from raw material to the hands of the customer.. •. The design flow, from its concept to its launching.. The Production flow will be studied, from the customer demand backing down to the raw material, which is the flow that usually is related to Lean Manufacturing, precisely the area in where the efforts are made to implement the lean methods.. Value Stream Mapping is a tool of pencil and paper that helps to see and to understand the flow of material and information of a product in its way through the value stream.. It’s simply to follow the production “road” of a product from the client to the supplier, and carefully to draw a visual representation of each process within the flow of materials and information, later some key questions raised that will help draw the map of the future state of how the value would have to flow.. Value Stream Mapping is a qualitative tool by means of which it is possible to describe in details how the factory would have to operate with the purpose of creating value. Value Stream Mapping helps to see and to focus in flow with a vision of an ideal or at least an improved future state.. Some advantages of Value Stream Mapping are the following ones: •. Help to visualize more than at level of the simple process.. 25.

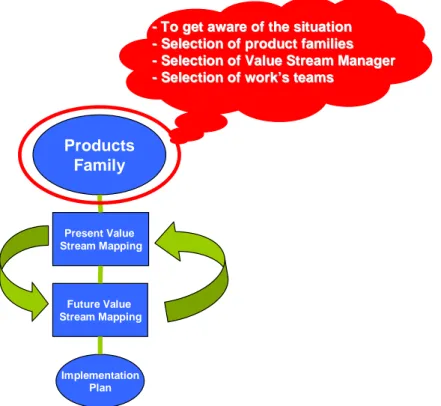

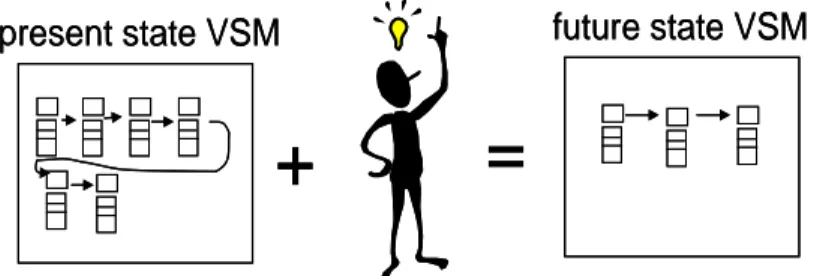

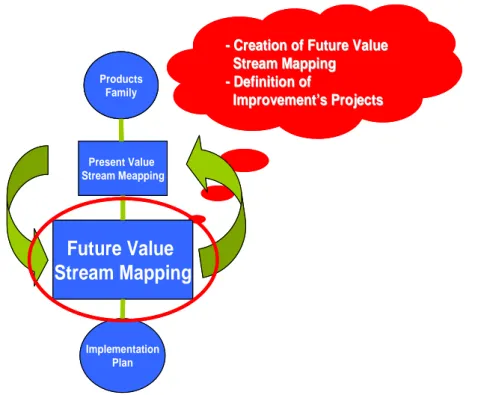

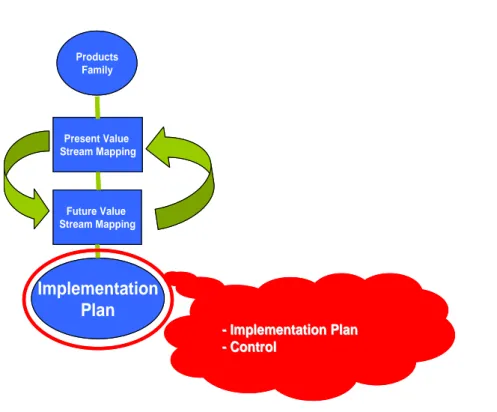

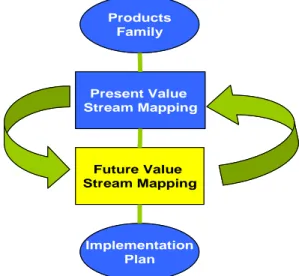

(36) Chapter II.- Research Fundamentals. •. Help to see more than the waste.. •. It provides a common language to speak about the manufacturing processes.. •. Take decisions about the flow of apparent value.. •. Binds the concepts and techniques of Lean Manufacturing. •. Show the league between the flow of information and the flow of materials.. The value stream mapping follows the next steps presented in the figure:. Products Family. Present Value Stream Mapping. Future Value Stream Mapping. Implementation Plan Figure 3 Value Stream Mapping Steps. It requires focusing in a product family. Value Stream Mapping means to walk and to draw the steps of the process (materials and information) for a products family from “door to door” in the organization.. It has to be identified the products family from the final client of the value flow, based on products that pass through similar processes and common equipments in the downstream process.. Note that the future state is marked, because the goal is to design and present a lean value stream. A present state without a future state is not of much utility. It always must have a map of the future state. 26.

(37) Chapter II.- Research Fundamentals. The arrows between the present and future state are overlapped efforts. The ideas of the future state will arise while the present value stream mapping is constructed.. The final step is to prepare and to begin actively to use an implementation plan. This plan describes in one page how it is planed to realize the transition of the present to the future state. As much as the future state becomes reality, the process of mapping is repeated because always is required a future state. This is the continuous improvement at value stream level. Next Future State. Future State. Present State. Original State Figure 4 Continuous Improvement in VSM. 2.4.2 INFORMATION AND MATERIALS STREAM Within the production flow, the movement of the material through the plant is the flow that usually come us to the mind. But it exist another flow - the information flow - that it is in charge of determining what to do in each process.. The flow of materials and information are both sides of “the same coin”. Both flows could be mapped.. PRODUCTION FLOW. Figure 5 Materials and Information Flows. 27.

(38) Chapter II.- Research Fundamentals. Information flow in Lean Manufacturing is dealt with the same importance that the materials flow. 2.4.3 VALUE STREAM MANAGER Consider that drawing the value stream from a product family requires crossing the organizational boundaries of the company. Since the companies tend to be organized by departments and functions, then nobody is responsible for the perspective of value stream.. In order to avoid these isolated areas of functionality a person is required to understand the value stream from a product family as well as of their improvements. This person is called Value Stream Manager and some of their functions are:. •. He Reports to main direction.. •. He is a person of line not of the staff.. •. He directs the creation of the present and future state value stream mappings. and the plan of implementation to arrive from the present state to the future state. •. Supervise all the aspects of the implementation. •. Every day is present in the place of the implementation.. •. He makes of the implementation the main priority.. •. He maintains and periodically updates the implementation plan.. The team in charge of mapping and implementation of the future state of the value stream needs to be directed by a person able to see through the organizational limits on which the value of a product flows.. 28.

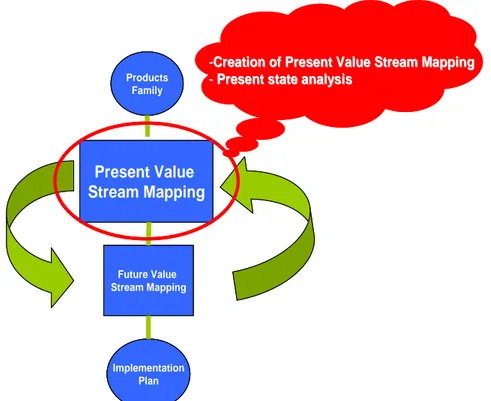

(39) Chapter II.- Research Fundamentals. The improvement of value stream – “Kaizen Flow” - is manager by Kaizen. The Kaizen flow supposes the accomplishment of a “Kaikaku” (initial radical change). 2.4.4 PRESENT VALUE STREAM MAPPING The Purpose of the present state is to document the actual situation of production through the drawing of the materials and information flows.. The map begins at the “door to door” flow level in the organization, where categories are drawn of process like “joint” or “welding”, instead of registering each step of the process. Symbols or icons are used to represent the processes and flows (we can see it in annex 2, although each company can develop its own symbols or icons). Once the flow through the organization has been seen, the level of detail can be changed; drawing the map in each individual step inside a process, or moving away to include the external value stream of the company.. Some considerations to realize a Value Stream Mapping are: •. Always collect information of the present state while one walks throughout the. real routes of the materials and information flows. •. Begin with a fast long walk throughout the value stream, to obtain the flow. direction and the process sequence. •. Begin in the shipping area upstream with the purpose of beginning with the. processes more directly related with the client. •. The ability to visualize a future value stream mapping depends to go personally. where it is the action and to understand and to take time from which is happening. •. Map the value stream personally (a single person).. •. Always draw by hand, with pencil and paper. To resist the temptation to use a. computer. 29.

(40) Chapter II.- Research Fundamentals. 2.4.5 FUTURE VALUE STREAM MAPPING The purpose of value stream mapping is to stand out the waste sources and to eliminate them by means of the implementation of the future state of a value stream mapping that can be obtained within a short period of time.. The goal is to construct a production chain where the individual processes are bound to their clients or by means of the continuous flow or a “pull” system, and that each process is so nearly possible to only produce what the client requires and when requires it.. Obvious, something of waste in the value stream will be the result of the process’s design, the machinery already bought, and the remote location of some activities.. These characteristics of the present state probably cannot be changed immediately. The first iteration of the map of the future state must consider product design, process technologies, and location of the organizations as well as look for and remove all the possible sources of waste no caused by these characteristics. The following iterations can consider the design of the product, technologies and location in general.. DEMAND ¿What is the Takt Time, based on the available working time of the downstream processes that are closest to the customer? ¿Will you build to finished goods supermarket from which the customer pulls, or directly to shipping?. 30.

(41) Chapter II.- Research Fundamentals. MATERIAL FLOW ¿Where can you use continuous flow processing? ¿Where will you need to use supermarket pull system in order to control production of upstream processes?. INFORMATION FLOW ¿At what single point in the production chain (process controller) will you schedule production? ¿How will you level the production mix at the process controller? ¿What increment of work will you consistently release and take away at the process controller?. SUPPORT IMPROVEMENTS ¿What process improvements will be necessary for the value stream to flows as your future-state design specifies?. 2.4.6 IMPLEMENTATION PLAN Value Stream Mapping is not just a tool. Unless the future state that has been drawn is obtained, the value stream mappings will not be of utility.. The first steps to obtain the future value stream mapping are: •. Draw the actual state value stream mapping.. •. Draw the future state value stream mapping.. •. Any map at level of process more in detail or distribution diagrams are. necessaries. •. An annual plan of the value stream.. 31.

(42) Chapter II.- Research Fundamentals. The future state of the value stream mapping shows towards where it is wanted to go. It is required to create an annual value stream mapping that shows: •. Exactly what is planned to do and for when, step by step.. •. Measurable goals.. The first question that arises in the implementation plan is, ¿in what order the propose improvements should be implemented? In order to choose a departure point it is suggested to look for the areas: •. Where the process is well understood by people.. •. Where implementation success is highly possible.. •. Where it is possible to predict that the improvement will cause a greater impact.. Once identified these areas it becomes necessary to emphasize them in the future state map (with pencil) and to number them according to the implementation plan. The improvements to a specific area follow this pattern: •. They develop a continuous flow that operates based in the takt time.. •. They establish a “pull” system in order to control the production.. •. They implement the balance of the work load.. The improvement in the value stream mapping is responsibility of the direction. The direction requires to dedicate time and to learn until the point to be able to teach lean techniques and value stream mapping. A form is required to cause that people follow their leader, without hoping orders from him. It is required to change the organizational approach of departments to products.. The direction requires a “value stream mapping administrator” whose work is to direct to the people who operate the process, not only in manufacture but in all the functions of the business, and to take responsibility from the cost, quality and delivery of the product in the present state while the implementation of the future state goes.. 32.

(43) Chapter II.- Research Fundamentals. It is required to select a specialist in “lean promotion” that helps to the value stream mapping administrators to see the waste and to introduce the appropriate practices required to eliminate their source.. The group of specialists in “lean promotion” must be of the organization, direct changes, put emphasis when solving the problems, while pay attention to the present necessities of the organization and the client. The group or department of specialists in the “lean promotion” supports to the implementers and reports to the high direction.. 2.5 HUMAN FACTOR An organization is, in words of Schein, “one rational coordination of the activities of a certain number of people, that they try to obtain a purpose and common and explicit objective, by means of the division of the functions and the work, and through a hierarchical structuring of the authority and the responsibility”. An organization only exists when: 1) There are people able to communicate and who 2) are arranged to act jointly 3) to obtain a common objective. The human resources are those in which the people, basic elements of an organization, appear like work elements, which they use resources and they arrange the organization to acquire other also necessary resources.. 2.5.1 HUMAN FACTOR IN THE ORGANIZATIONS The Human Factor in the organizations develops in three scopes: 9 The man like Individual 9 The man in the Group 9 The man in the Organizations. 33.

(44) Chapter II.- Research Fundamentals. The Individual man. He studies the organizational conduct, as soon as behavior of an individual with own psychological characteristics and in a certain context.. The individual level has to do, among other things, with the characteristics and psychological processes of the people, the context of the individual, its labor position, its aptitudes, skills, abilities, competitions, beliefs, values, vocational interest, goals, expectations, etc. The yield and the performance of the employees are direct consequence of the motivation, satisfaction, stress and personal development of such.. The man in the Group. In the group level there are different types from groups and units that deliberately are designed (formal) or spontaneously created (informal). The job and information streams, the configurations, the technology and the tasks, the size of the group, the degree of professionalism of the members, the cohesion, the decision making, the leadership, the coalitions, the conflicts intra and intergroups, etc.. The man in the Organizations. The Organizational Level takes place in a social context ampler than the group within the framework of the company. In this level the context is considered in which it operates the company (political, cultural and social environment, market, location, economic conjuncture, competition, etc.). 34.

(45) Chapter II.- Research Fundamentals. 2.6 AUTOMOTIVE INDUSTRY The Automotive industry is a mature industry that presents problems like: saturated markets in the third world countries, installed capacity in excess, higher segmentation degrees and product proliferation, closed competition in prices and decreasing margins of utility.. The National Automotive Industry is composed by: terminal industry, car parts industry and by national suppliers of parts and components. First of them is integrated by the companies established in Mexico, that produce or realize the final joint of the automotive vehicles. When one talks about automotive vehicles, we are talking about: automobiles (in this category are the popular ones, compact automobiles, luxury and sport), trucks (commercial, light, medium, heavy trucks, chassis), tract trucks and buses. [AMIA, 2004]. The Second one is integrated by the companies that operate in the country, with an invoicing of parts and components destined to provide like original equipment to the established terminal industry in the country.. The classification given for the structure of parts and components is the following: The system a) electrical, b) Cooling, c) motors and their parts, d) transmission, suspension, direction and clutch, e) brakes and their parts, f) accessories, g) printings and their parts, h) glasses, i) carpets, seats and their parts. [INA, 2004]. The Third is denominated like national suppliers, and it is constituted by the set of companies that provide to the automotive industry parts and components.. At present, the environment that faces this industry is not very heartening, since it concentrates higher fixed costs, it develops in restrictive labor conditions and continuously it requires developing new technologies by competition and bye the changes of regulation in environmental aspects.. 35.

(46) Chapter II.- Research Fundamentals. The Mexican automotive industry does not escape to this difficult situation. In agreement with the most recent data emitted by the Mexican Association of the Automotive Industry (AMIA) and the Mexican Association of Distributors of Auto engines (AMDA), during the first two months of 2004 a growth of 3,2% in the sales of vehicles in the internal market with respect to the same period of the previous year was registered; nevertheless, a reduction in the production generated by the participation of imported vehicles is considered, since from each 10 cars sold in the national market, 6,5 come from abroad.. Figure 6. National Sales [AMIA]. In agreement with the AMDA, this situation origins that in 2003, Mexico has descended to the tenth first place at word-wide level like vehicles producer instead of the ninth place obtained in the 2002. On the other hand, in the first two months of 2004, AMIA reported a fall of 13.1% in exports of vehicles produced in Mexico.. Figure 7 Vehicles Exportation [AMIA]. 36.

(47) Chapter II.- Research Fundamentals. Nevertheless the difficult present situation of the automotive industry, Mexico is considered an excellent place to produce vehicles, being considered that has cheap manual labor and comparatively well prepared, combined to the existing facilities for this industry established in the relative laws.. This is reflected in the recent plans of investment of the main established automotive companies in Mexico, destined to the modernization and extension of its plants, as well as the establishment of diverse strategic alliances with object to assure the technology, training and material and human resources that allow them to face the adverse conditions that prevail in the market. An example of this is the investment programmed by the American shipbuilder Motor Ford Company, who plans to invest 1.600 million dollars in the city of Hermosillo for the extension of its facilities with a new line of joint. Another example is the one of the Japanese shipbuilder Nissan Motor Company who in the 2004 decided to increase substantially his investments, which will be canalized to increase the capacity of construction of motors and transmissions. In the 2005 this important company will try to send a new line of vehicles that will be assembled in Mexico, with object to increase his participation in the national market from 20% to 22%. Additionally, Johnson Controls Inc., main world-wide supplier of systems for the automotive industry, announced that he will carry out the transfer to Mexico of the production of mirrors for automobiles and trucks of two plants located in the United States of America. This operation represents a generation of 1.800 employments in the country. The level of the manufacturing industry of Nuevo Leon incorporates efforts again to be supplier of raw materials and material for the automotive industry. Most of the car companies of auto parts and materials for the industry counts on with certificates of quality "QS", considered like ticket of entrance as supplier of the terminal industry. 37.

(48) Chapter II.- Research Fundamentals. 2.7 ELECTRONIC INDUSTRY The electronic industry in Mexico arises during the Sixties with the manufacture of electronic products of consumption like stereophonic and televising radio receivers, consoles, phonographs, etc. Towards the Seventies, the policy of substitution of imports stimulates the growth of the sector sustained solely in the national market. However, the lack of external competition originated the low development of manufacturers of components, as well as delays in the adoption of new technologies.. In 1986, Mexico joins to the General Agreement on Tariffs and Commerce, giving origin to an important reconstruction of the electronic industry. From this year an important exporting sector initiates his development, sustained mainly in the assembly plants, besides of the growth in parallel form the companies conducted to the internal market.. With the entrance of the Free Trade Agreement of North America in 1994, the electronic industry obtains an important impulse. The preferential entrance of Mexican products to the market of North America, as well as the access to parts and components imported to competitive prices, stimulated the growth of the exports, the attraction of foreign investments and the generation of employments.. However, the low level of competitiveness developed by the manufacturing companies of components and electronic raw materials destined to the internal market caused its virtual disappearance, in addition to its substitution by new manufacturers of components. Consequently, the segment of the oriented electronic industry to the internal market, was guide to a sector with degrees of national integration of until 80 percent but overprotected and inefficient, towards one competitive industry that by effect of the opening and the external competition, now reaches average levels of integration of 14 percents, and 5 percents specifically in the industry assembly plant.. 38.

(49) Chapter II.- Research Fundamentals. The companies that operate under the assembly plant scheme distinguish of the rest of the electronic industry as a result of the high levels of globalization in their productive processes, reason why they must import great part of the raw materials, parts and components that use.. In the international scene, from December of 1996, 56 countries create in the framework of the OMC the International Information Technology Agreement. By means of this Agreement, the participant countries decided to reduce to rate zero in a term of four years, all the taxes of import of intermediate products and final consumption related to the information technologies. The characteristics and cover have originated that more than the ninety percent of the international trade of products of these sectors, at the moment is made under this agreement. Mexico, for not being member of this Agreement, will have to take actions that allow maintaining the competitiveness in duty, according to the new conditions of the international environment.. The electronic sector in Mexico had a very favorable evolution during the Nineties, especially towards second half of the decade. The leadership of this sector has continued at the beginning of this century, being obtained to consolidate like one of the industries with greater participation in the national manufacturing sector.. Sustained in companies mainly directed to the export markets (PITEX4 and assembly plants), in the 2001 electronic industry represented an important source of growth of the Gross Domestic Product of the manufacturing sector (5.8 percents) and of generation of employments (9,3 percents in the manufacturing sector), besides to generate one of the greater commercial interchanges with the external (30 percents of the exports).. 39.

(50) Chapter II.- Research Fundamentals. The electronic industry in Mexico includes the branches of audio and video, computers, telecommunications, commercial equipment and office equipment, electronics measurement and control, biomedical electronic and parts for automotive vehicles. Each one of these branches makes in Mexico great variety of products, some of which are detailed next. [DGI, Secretary of Economy 2003]. AUDIO AND. CÓMPUTER. VIDEO. PARTS AND COMPONENTS. OFFICE AND TELECOMUNICATIONS. COMERCIAL EQUIPMENT. Television. PC’s. Modular Circuits. Telephonic Centrals. Photocopier. Chassis. CPU’s. Power Supply. Telephonic Devices. Typewriters. Radio recorders. Notebooks. Kinescopes. Cellular Phones. Calculators. Video recorders. Monitors. Yokes deflection. Radio Equipment. Cash register. Auto radios. Printers. Channel Tuner. Telephonic Transmission Equipment. Table 1 Electronic Industry branches, [Secretary of Economy 2003]. In Mexico work original producing plants of the leader’s countries in the electronic industry, mainly of the U.S.A. and Japan. Besides, these plants have been concentrated in different regions from the country, which has allowed the development of important industrial groups (clusters), in the North zones, the West and center of the country. Also, it has been developed a specialization at a regional level by type of product, distinguishing itself four great groups by value of production: Baja California in the manufacture of audio and video equipment;. 40.

(51) Chapter II.- Research Fundamentals. Jalisco in the segment of computer equipment and telecommunications; State of Mexico in telecommunications; and Chihuahua in video and audio products.. In Nineties, the electronic industry in Mexico had his greater peak. During those years they settled down, besides to a great amount of assemblers companies, organizations that generated investments in some areas of supplies like plastic, metallic, cables, harnesses and packing. To this process contributed important internal and external factors.. Moreover to the internal and external factors that in one way impulses the development of the electronic industry during the Nineties, three competitive advantages exist that have allowed Mexico to be placed like a strategic center of production and businesses at world-wide level:. 1. Demographic dynamic; 2. Geographic position; and 3. The commercial treaty network.. However, these advantages must be supported with political and actions that allow their fortification, in order to adapt them to the new conditions of competition that impose the processes of globalization and opening of the electronic industry. In case of not being adopting a consistent vision to this new environment, the competitive advantages of Mexico will be losing effectiveness until disappearing completely, eliminating the electronic industry of any possibility of continuing competing in the international markets.. 41.

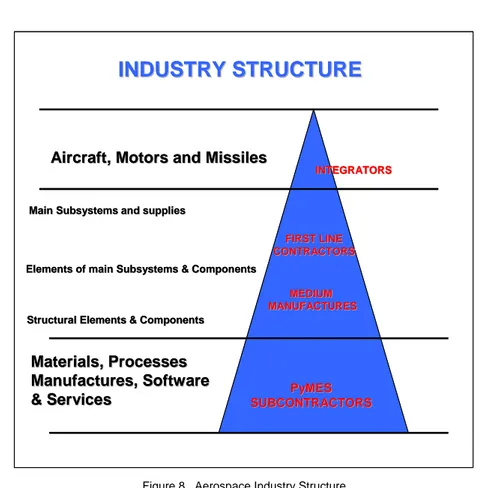

(52) Chapter II.- Research Fundamentals. 2.8 AEROSPACE INDUSTRY The aerospace industry of the United States of America is at the top of the aerospace industry with nearly half of the world-wide production. Maintained by a goodwill leadership, it constitutes the reference in the sector, as much as for the innovation as in the reach of the product range. The European Union is in second position with a production nearly half of one of the United States.. It constitutes his main competitor, especially in the. sectors of the civil aviation and the space. As far as Russia, it has inherited of the Soviet Union an elevated technological level, but its capacity has been degraded because of its economic difficulties. Behind the dominant countries are emergent capacities of forward edge, that is, those of countries that seek to have an aerospace industry able to locate them between the great ones: one is concretely about China, Japan and India, three great nations that aim at different geostrategic objectives, but that they want to have means of the great countries. Its situation is characterized by the fact that they practically are absent in the sector of the civil aviation, whereas they are already in a phase outpost within the space sector, basis fundamentally in cooperation with the more advanced countries. Canada and Brazil have become world-wide suppliers of regional airplanes. On the other hand, Israel has happened to be leader in the manufacture of tactical and ballistic missiles. Other countries exist besides at the same time persecuting economic and military objectives in the development of their aeronautical policy. We can mention like examples Indonesia, Taiwan, South Korea, Australia and Turkey. We can consider that the aerospace industry treated globally follows two tendencies. First it goes in the sense of the dispersion based on national considerations that concern mainly to the defense. Second, of economic nature, it. 42.

Figure

![Figure 1 Determinants of the national competitive advantage [Porter]](https://thumb-us.123doks.com/thumbv2/123dok_es/2286831.514943/15.892.276.618.159.495/figure-determinants-national-competitive-advantage-porter.webp)

![Figure 6. National Sales [AMIA]](https://thumb-us.123doks.com/thumbv2/123dok_es/2286831.514943/46.892.215.676.420.629/figure-national-sales-amia.webp)

![Table 1 Electronic Industry branches, [Secretary of Economy 2003]](https://thumb-us.123doks.com/thumbv2/123dok_es/2286831.514943/50.892.116.777.336.799/table-electronic-industry-branches-secretary-economy.webp)

Documento similar

teriza por dos factores, que vienen a determinar la especial responsabilidad que incumbe al Tribunal de Justicia en esta materia: de un lado, la inexistencia, en el

In the preparation of this report, the Venice Commission has relied on the comments of its rapporteurs; its recently adopted Report on Respect for Democracy, Human Rights and the Rule

The draft amendments do not operate any more a distinction between different states of emergency; they repeal articles 120, 121and 122 and make it possible for the President to

In the case of crosstalk and reference masses, this value is the most intense peak in the MS 2 spectrum; while for coelution of isobaric species, the value is given

Nuestra implicaciones teóricas se centran en el sector de las PBFs, donde se han realizado dos estudios que colaboran de un modo activo y eminentemente

The purpose of the research project presented below is to analyze the financial management of a small municipality in the province of Teruel. The data under study has

In the “big picture” perspective of the recent years that we have described in Brazil, Spain, Portugal and Puerto Rico there are some similarities and important differences,

Chapter 3 developed a measure for shareholder value orientation of ex- ecutives and classified 38 Spanish and European companies 10 according to their orientation towards